3.2.

Inspection and Measurement

3.2.1.

Cylinder block

1) Clean the cylinder block thoroughly and make a visual inspection for cracks or damage.

2) Replace if cracked or severely damaged, and correct if slightly damaged.

3) Check oil and water flow lines for restriction or corrosion.

4) Make a hydraulic test to check for any cracks or air leaks.

Hydraulic test

Stop up each outlet port of water/oil passages in the cylinder block, apply air pressure of about

4kg/cm

2

against the inlet ports, then immerse the cylinder block in water for about 1 minute to

check any leaks. (Water temperature: 70

˚C)

3.2.2.

Cylinder head

1) Inspection

•

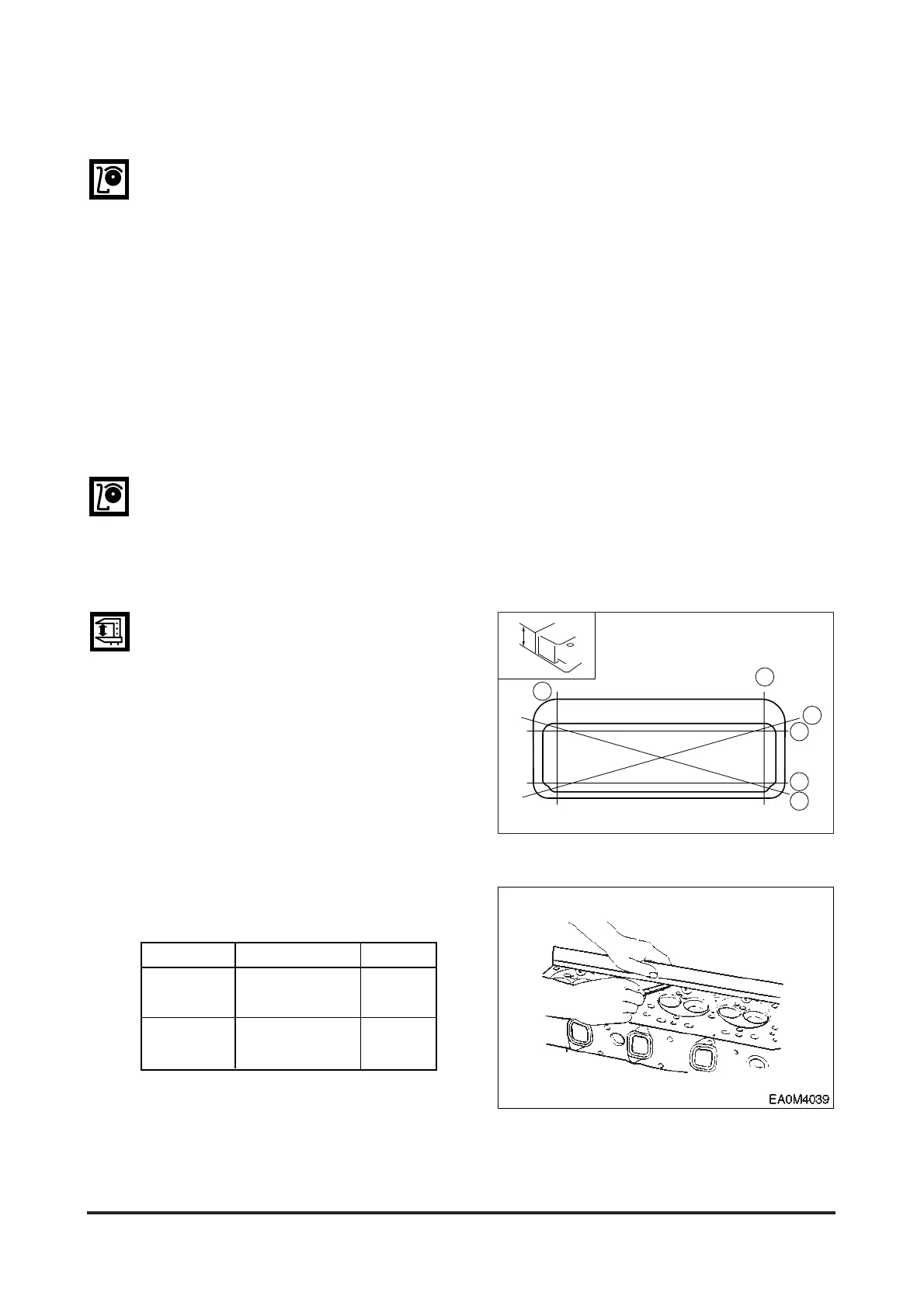

Carefully remove carbon from the lower lace of the cylinder head using nonmetallic materi-

al to prevent scratching of the valve seat faces.

•

Check the entire cylinder head for very fine cracks or damage invisible to ordinary sight

using a hydraulic tester or a magnetic flaw detector.

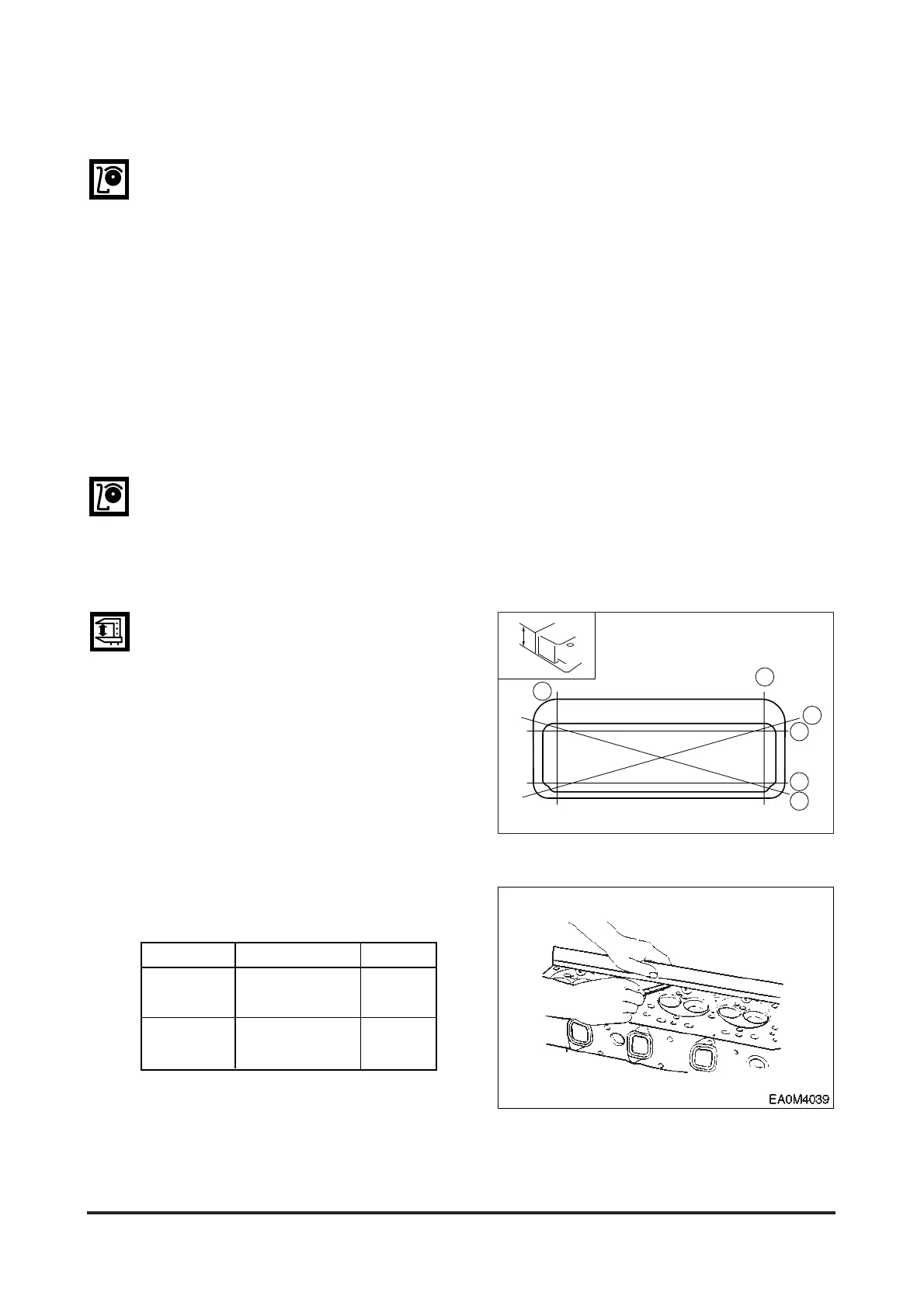

2) Distortion at the lower face

•

Measure the amount of distortion

using a straight edge and a feeler

gauge at six positions (A ~ F) as

shown in the right figure.

•

If the measured value exceeds the

standard value, retrace the head with

grinding paper of fine grain size to cor-

rect such defect.

•

If the measured value exceeds the

maximum allowable limit, replace the

cylinder head.

Low face warpage and height

- 61 -

INSPECTION AND MEASUREMENT

Loading...

Loading...