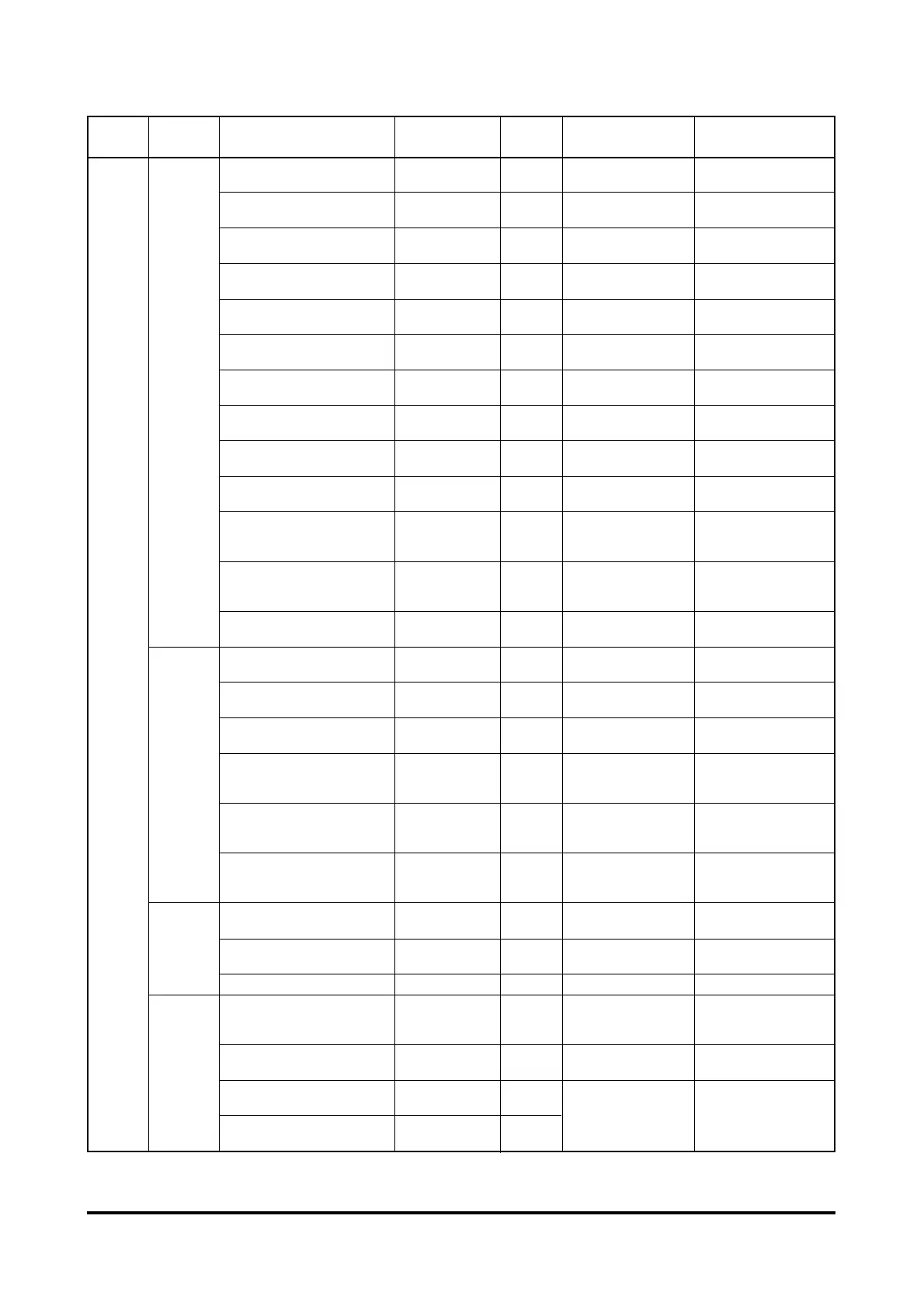

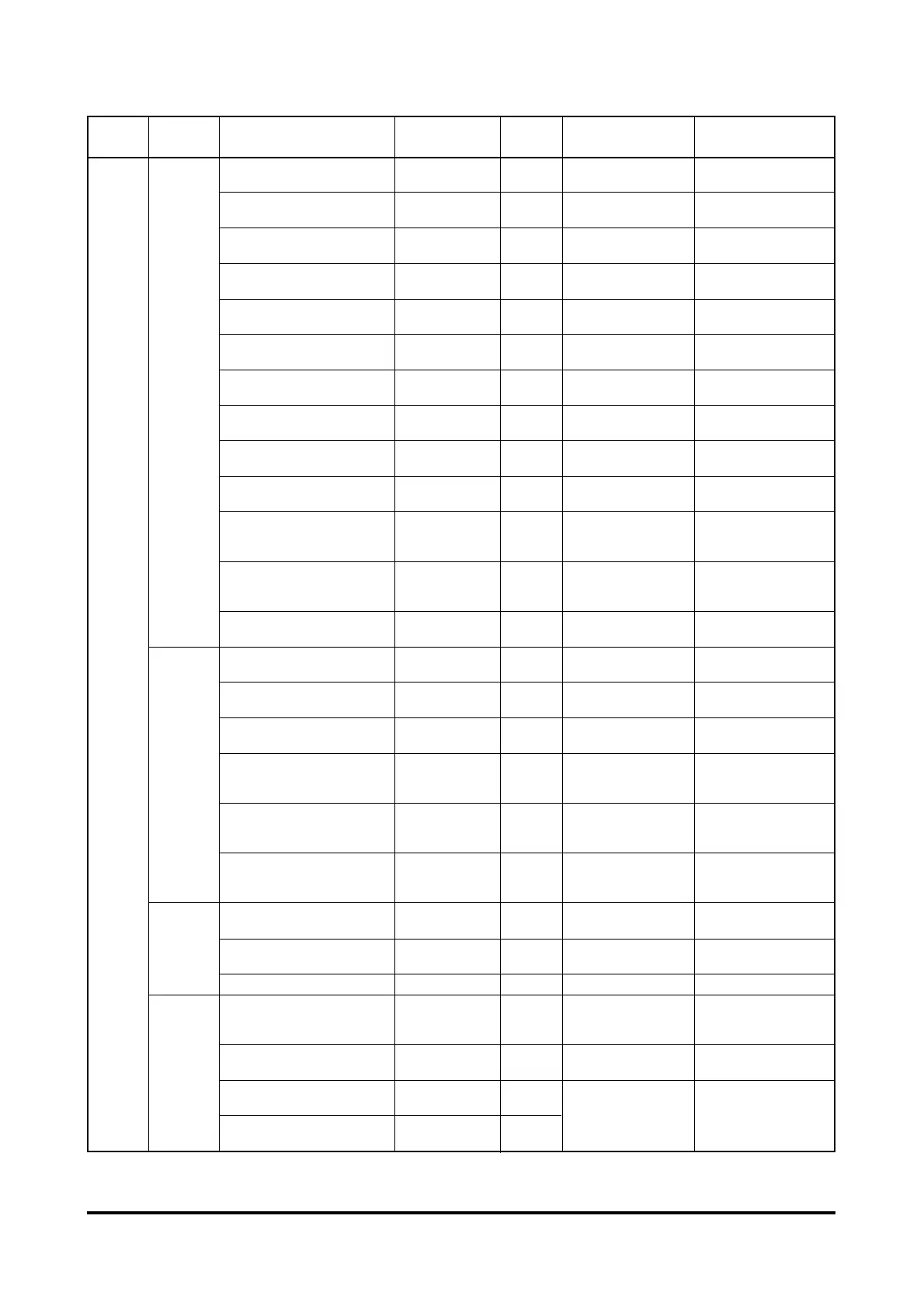

(unit : mm)

- 179 -

APPENDIX

Group Part Inspection Item

Stand value Limit

Correction Remark

for assembly for use

Axial run-out of journal

0.05 0.1

Correct In horizontal and

and pin with a grinder vertical directions

Outside diameter of

N

95.966 ~

N

94.966

Replace crankshaft N

96 g6

journal

N

95.988

Outside diameter of pin

N

82.966 ~

N

81.966

Replace crankshaft N

83 g6

N

82.988

Out of round of journal

0.008 0.025

and pin

Permissible radial run

0.01 0.03

out of journal and pin

Permissible taper of

0.02 0.03

journal and pin

Crank Clearance between

0.072 ~ 0.142 0.25 Replace bearing

Measure in the

shaft crankshaft and bearing position of crown

End play of crankshaft 0.15 ~ 0.325 0.5

Replace

thrust bearing

Run out of crankshaft 0.1

0.15 or Adjust by a press No.4 bearing

less if bent (holding no.1 & 7)

Balance of crankshaft 60

60 or Check dynamic Measure

less balance at 400 rpm

Tightening torque of No foreign, matters

journal bearing cap bolt 30 - Apply oil to bolt on bearing cap

(kg

•

m) install surface

Measure by tightening

Journal bearing crush 0.11 ~ 0.13 - metal cap & then

Major

loosening one stud bolt

moving

Oil seal for wear - -

Replace oil seal Replace with new

parts

if oil leaking one, use shim

Clearance between con-

0.049 ~ 0.119 0.20 Replace bearing

rod bearing & crank pin

End play of con-rod

0.22 ~ 0.319 0.5 Replace con-rod

crush

Clearance between small

0.050 ~ 0.080 0.12

end bush & piston pin

Connec-

Connecting rod bearing

After completing of

ting rod

crush height

0.086 ~ 0.116 - bearing loosen one

stud bolt & measure

Permissible weight

difference of each con-

L

18 g -

rod

Tighening torque of

con-rod bearing cap bolt 28 - Apply oil to bolt

(kg

•

m)

Outside diameter of cam

N

59.860 ~

N

59.52

N

60

shaft

N

59.880

Cam

Clearance between cam

0.050 ~ 0.128 0.20

shaft

shaft and bush

Axial play of camshaft 0.13 ~ 0.27 0.30

Replace thrust place

Clearance between idle

gear shaft and inserting 0.025 ~ 0.091 0.15

hole

Timing

End play of idle gear

0.043 ~ 0.167 0.3

Replace thrust collar

gear

shaft

Between crank gear &

0.10 ~ 0.20 -

idle gear

Replace gear

Between idle gear &

0.10 ~ 0.20 -

camshaft gear

Loading...

Loading...