www.DaikinApplied.com 23 IM 817-7

Typical Valve Packages

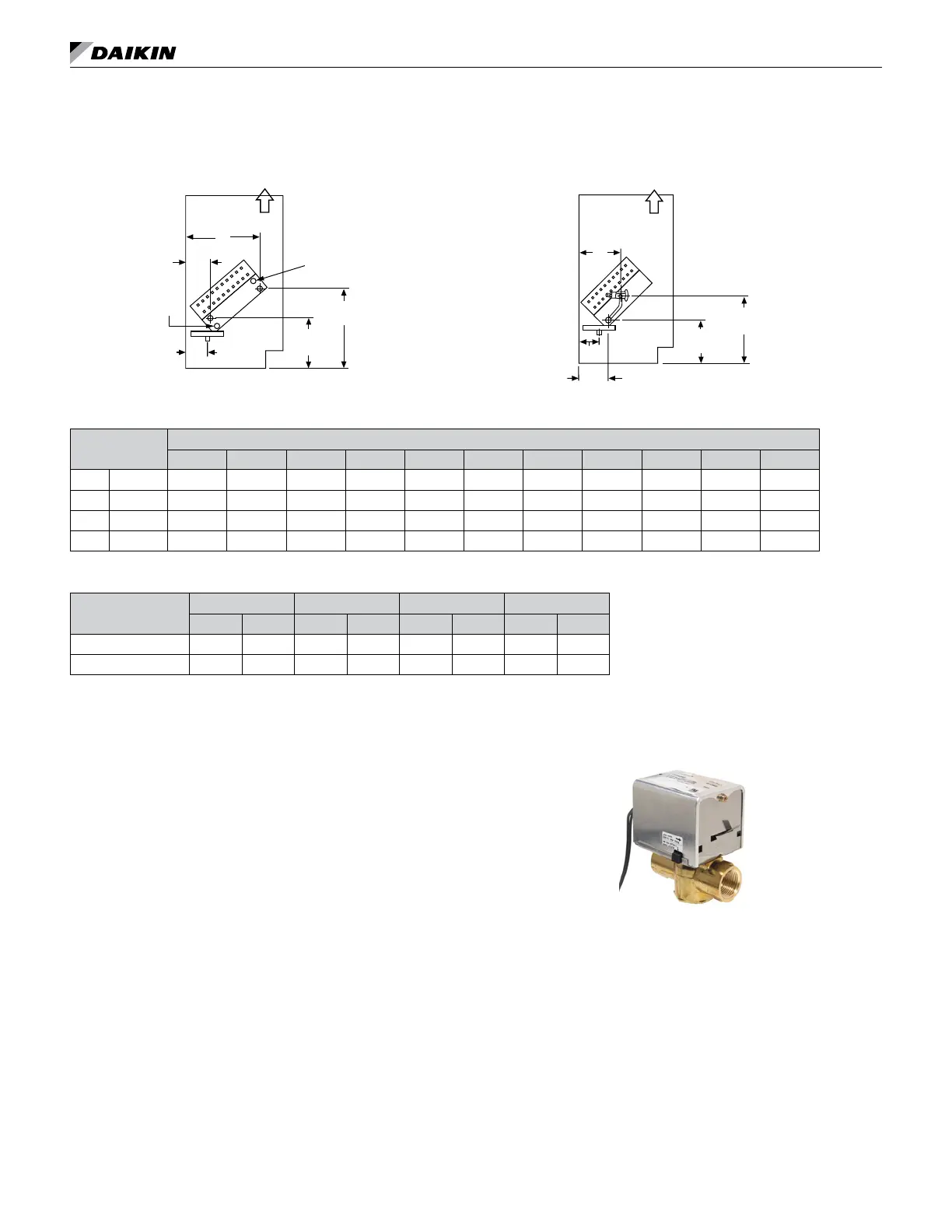

The optional factory-supplied Daikin Control Valve(s) for

water applications are either 2-way or 3-way type, and

are shipped separate from the unit ventilator itself to help

avoid shipping damage to the piping of the connection

stub from the weight of the valve, and to provide the

installer with maximum exibility in making the eld

piping connection. Before proceeding, see Figure 69

through Figure 92 as applicable, as well as the job-

specic piping drawings.

Notes:

1. See label furnished on 2-way valve to determine direction of ow through the

valve.

2. Adhere to the port orientation shown for the 3-way valve.

3. For hot water applications and chilled water/hot water (2-pipe) applications,

the 2-way valve furnished is normally piped open to the coil; the 3-way valve

is piped normally open to the coil.

4. For chilled water applications, the 2-way valve furnished is normally piped

closed to the coil; the 3-way valve is piped normally closed to the coil.

5. The 3-way valve is generally selected for diverting water back to the return

main, where a constant pump head pressure is required.

6. All water coil stubs are 7/8” I.D. female sweat. Coil connections terminate 9”

(229mm) from the end of the unit. Hot water connections may be same end as

cooling coil connections, but are recommended to be at opposite ends from

each other. When using MicroTech controls, they must be at opposite ends.

Face & Bypass End of Cycle Valves

2-Way End of Cylce Valve

When piping the 2-Way End of Cycle valve, refer to label

to determine the direction of ow. The valve should be

installed so that there is a 2” (51mm) minimum clearance

to remove the actuator from the valve body. Provide

unions for removal of unit coil and/or control valve as

a future service consideration. Hot water connections

may be same end as cooling coil connections, but are

recommended to be opposite end to facilitate piping.

When using MicroTech® controls, they must be opposite

end. The End of Cycle valve accessory must be eld

installed on the unit for which it was selected.

Chilled Water and Electric Heating Coils

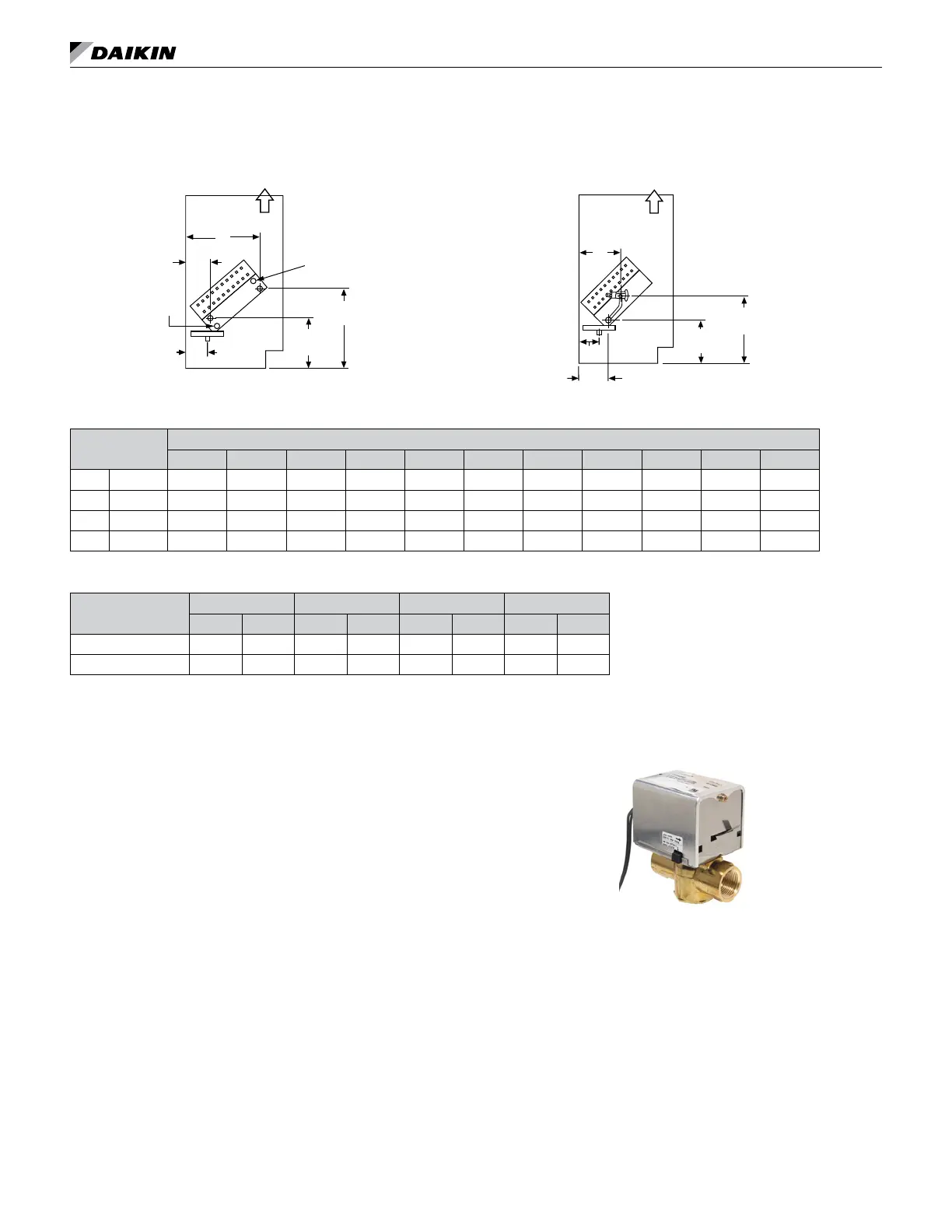

Figure 67: Chilled Water (1st Position) and Electric Heating

(Cooling Coils V[5], S[6], W[7]), (Heating Coils 12, 13)

R

S

13-3/4"

(350mm)

A

B

J

8-1/2"

(216mm)

Air Flow

Vent

CW

Direct Expansion and Electric Heating Unit

Figure 68: Direct Expansion (1st Position) and Electric

Heating (Cooling Coils G[9]), (Heating Coils 12, 13)

LL = Liquid Line

SL = Suction Lin

LL

SL

J

D

C

7-1/4"

(184mm)

Air Flow

11-3/4"

(299mm)

Table 8: Coil Connection Dimensions For Lettered Values

1

Unit Depth

Dimensions

A B C D E F G H I J K

in. 16-5/8 3-3/4 12-1/4 4-7/8 7-3/4 1-5/8 10-1/8 2-3/4 2-7/8 5-5/8 3 5

mm 422 95 311 124 198 41 257 70 73 143 76 127

in. 21-7/8 9 17-1/2 10-1/8 13 6-7/8 15-3/8 8 8-1/8 10-7/8 8-1/4 10-1/4

mm 556 229 445 257 330 175 391 203 206 276 210 260

Table 9: Direct Expansion (DX) Coil G[9] Connection Tubing

Unit Series

07 10 13 15

in mm in mm in mm in mm

Suction Line OD: 3/4 19 3/4 19 7/8 22 7/8 22

Liquid LIne OD: 1/4 6.35 1/4 6 3/8 10 3/8 10

Loading...

Loading...