www.DaikinApplied.com 29 IM 817-7

Steam Modulating Valve Selection

The steam modulating control valve is expected to vary

the quantity of steam through the coil. Any movement

of the valve stem should produce some change in the

steam ow rate. To select a modulating steam valve:

1. Obtain the supply steam inlet pressure.

2. Determine the actual heat requirement of the space

to be heated.

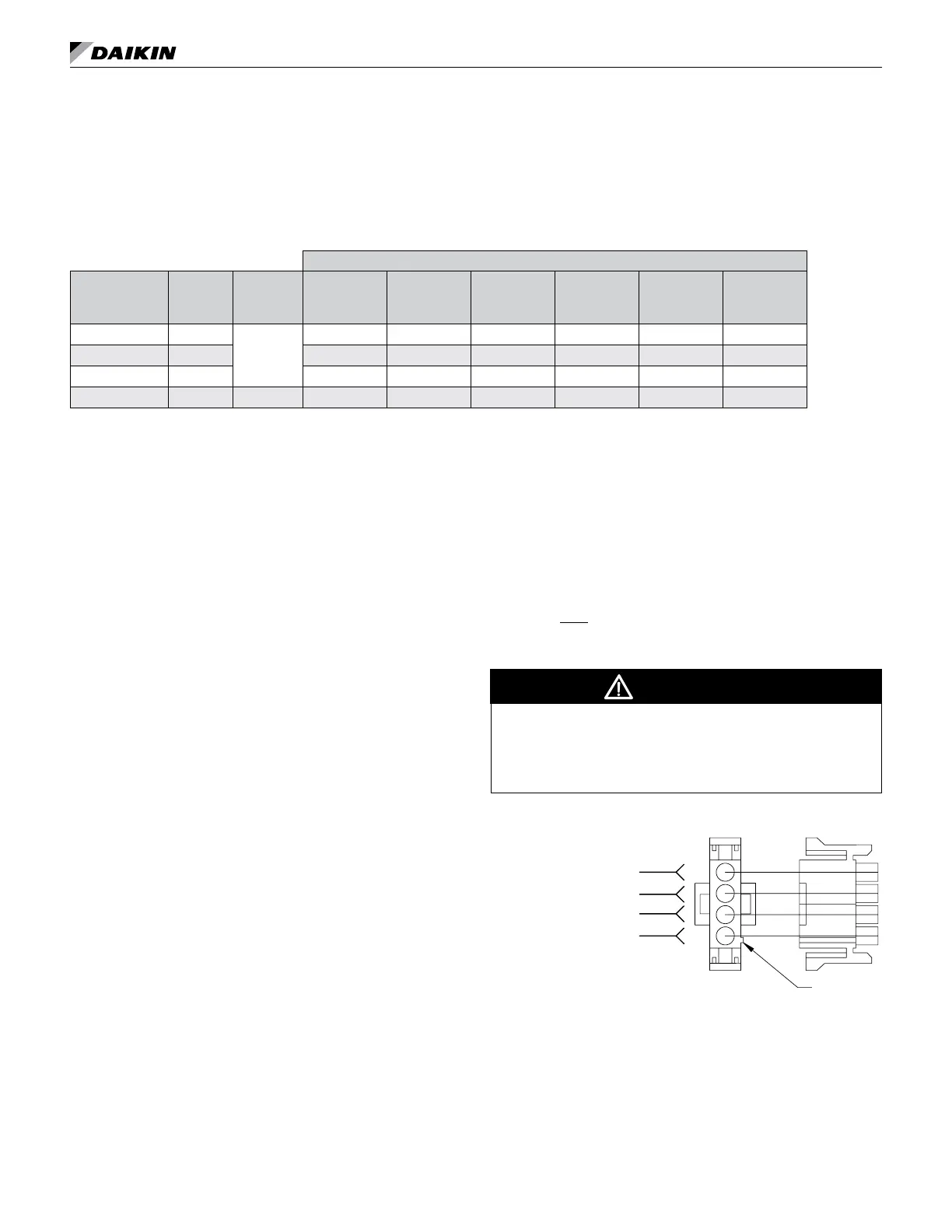

Table 28: Modulating 2-Way, Normally Open, Steam Valves – Pressure Drop

Pressure Drop Across the Valve

2-Way CCV Part

No.

Cv

Maximum

Rating

Connection

Size

2 PSI 3 PSI 4 PSI 5 PSI 10 PSI 15 PSI

B215HT073 0.73

1/2"

10.99 13.71 16.11 18.33 28.03 36.74

B215HT186 1.86 22.34 34.93 41.06 46.70 71.42 93.60

B215HT455 4.55

54.65 85.44 100.43 114.24 174.72 228.97

B220HT731 7.31

3/4 inch 110.02 137.27 161.36 183.54 280.70 367.86

2-Way and 3-Way Hot Water and

Chilled Water Modulating Valve

Selection

The unit ventilator control valve is expected to be able

to vary the quantity of water that ows through the coil in

a modulating fashion. Any movement of the valve stem

should produce some change in the amount of water that

ows through the coil. Oversized control valves cannot do

this. For example, assume that when the control valve is

fully open, the pressure drop through the coil is twice as

great as the drop through the valve. In this case, the control

valve must travel to approximately 50% closed before it

can begin to have any inuence on the water ow through

the coil. The control system, no matter how sophisticated,

cannot overcome this. Oversized control valves can also

result in “hunting” which will shorten the life of the valve and

actuator and possibly damage the coil.

To correctly select the proper Chilled Water Modulating

Valve:

1. Determine the ow of water and the corresponding

pressure drop through the coil.

2. Obtain the pressure difference between the supply

and return mains.

3. Select a valve size (Cv) from Table 28, on the basis

of taking 50% of the available pressure difference (at

design ow) between the supply and return mains at

the valve location. The valve should have a pressure

drop greater than that of the coil.

Figure 76: Formula Equation to Calculate Cv

Q = Capacity in gallons per minute

Cv = Valve sizing coefcient determied experimentally

for each syle and size of valve, using water at

standard conditions as the test uid

∆P = Pressure differential in psi

G = Specic gravity of uid (water at 60°F = 1.0000)

Cv = Q

�

G

∆P

CAUTION

Care must be taken with modulating valves to provide proper

water ow. In freezing conditions, water ow must be maintained

through the heating coil or a suitable freeze-prevention solution

employed to prevent freeze-up. Similarly, the cooling coil must be

drained or a suitable freeze-prevention solution employed.

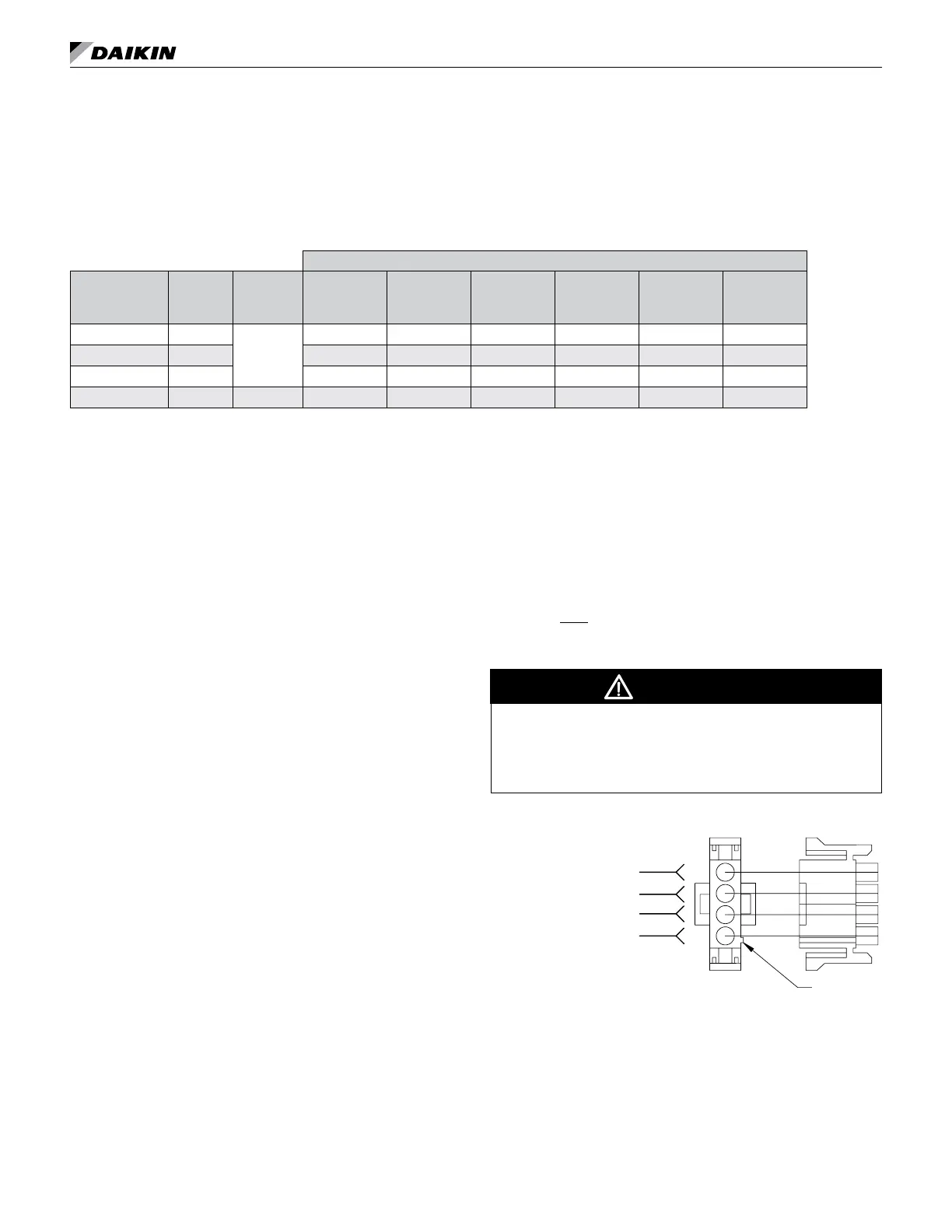

Figure 77: Actuator Wiring

WHT (Input 2 to 10 VDC)

RED (24VAC Supply)

(Output 2 to 10 VDC)

BLK (Common)

BLK

WHT

ORG

RED

Note: The actuator spring returns the valve to the open

position when the actuator is de-energized (off)

Loading...

Loading...