1-41 Motor Angle Offset

Range: Function:

0

*

[0 - 65535] Enter the correct offset angle between the PM motor and the

index position (single-turn) of the attached encoder or resolver.

The value range of 0 – 65535 corresponds to 0 - 2 * pi (radians).

To obtain the offset angle value: After drive start-up apply DC-

hold and enter the value of par. 16-20

Motor Angle

into this

parameter.

This parameter is only active when par. 1-10

Motor construc-

tion

is set to

PM, non-salient SPM

[1] (Permanent Magnet Mo-

tor).

2.4.5. 1-5* Load Indep. Setting

Parameters for setting the load-independent motor settings.

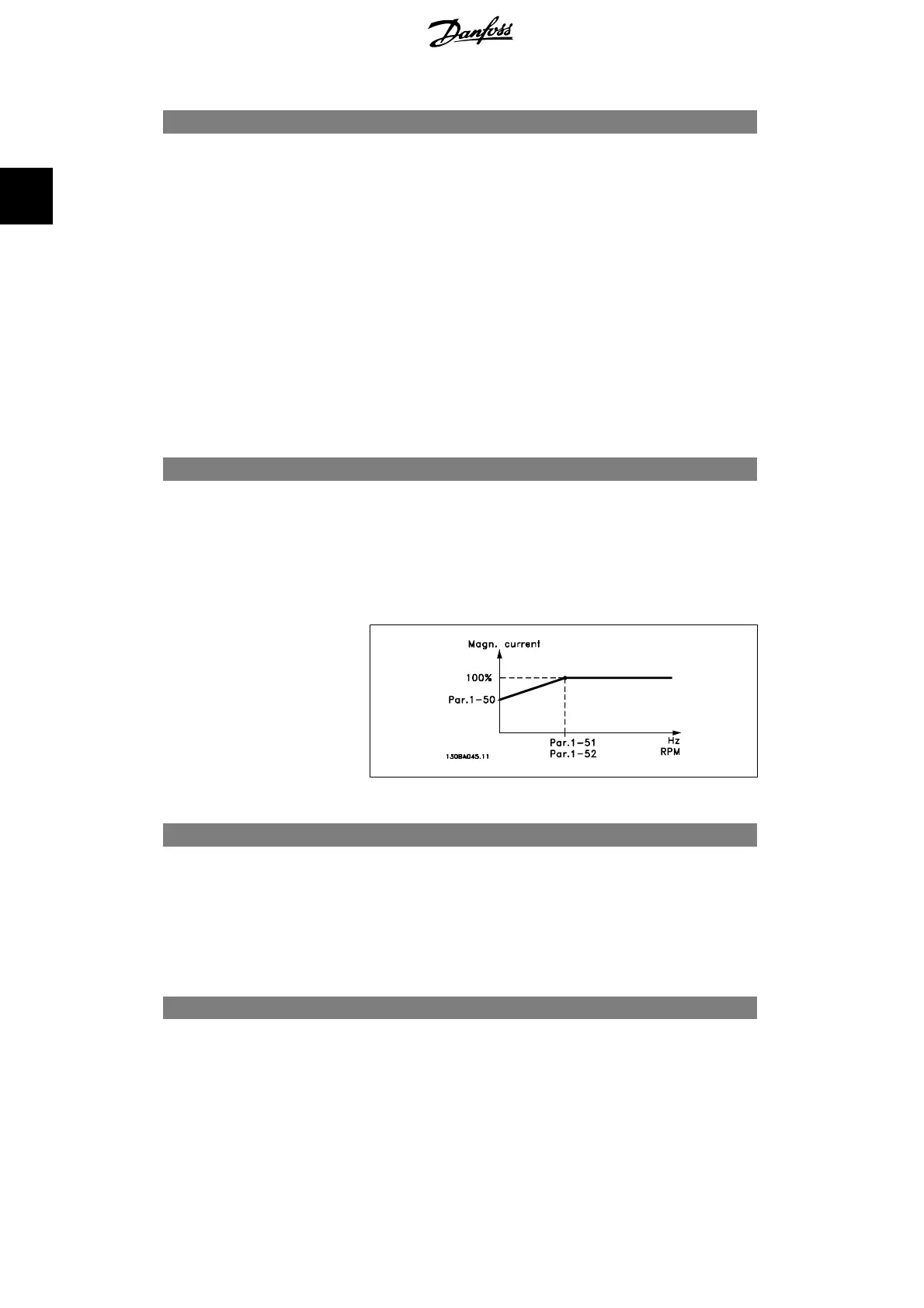

1-50 Motor Magnetisation at Zero Speed

Range: Function:

100% [0 - 300 %] Use this par. along with par. 1-51

Min Speed Normal Magnetis-

ing [RPM]

to obtain a different thermal load on the motor when

running at low speed.

Enter a value which is a percentage of the rated magnetizing

current. If the setting is too low, the torque on the motor shaft

may be reduced.

1-51 Min Speed Normal Magnetising [RPM]

Range: Function:

15

RPM

*

[10 - 300 RPM] Set the required speed for normal magnetising current. If the

speed is set lower than the motor slip speed, par. 1-50

Motor

Magnetisation at Zero Speed

and par. 1-51 are of no signifi-

cance.

Use this par. along with par. 1-50. See drawing for par. 1-50.

1-52 Min Speed Normal Magnetising [Hz]

Option: Function:

[Size re-

lated]

0 - 250 Hz Set the required frequency for normal magnetising current. If

the frequency is set lower than the motor slip frequency, par.

1-50

Motor Magnetisation at Zero Speed

is inactive.

Use this par. along with par. 1-50. See drawing for par. 1-50.

2. How to Programme FC 300 Programming Guide

50

MG.33.M2.02 - VLT

®

is a registered Danfoss trademark

2

Loading...

Loading...