5. Testeachpintoground;readingshouldbeopenorinfinite.

6. Iftheintegrityofthebearingsensorfeedthroughisinquestion,isolatethecompressor,recoverthe

refrigerantaccordingtoindustrystandards,removethefeedthroughandrepeattheabovesteps

directlyattheinternalsensorconnector.

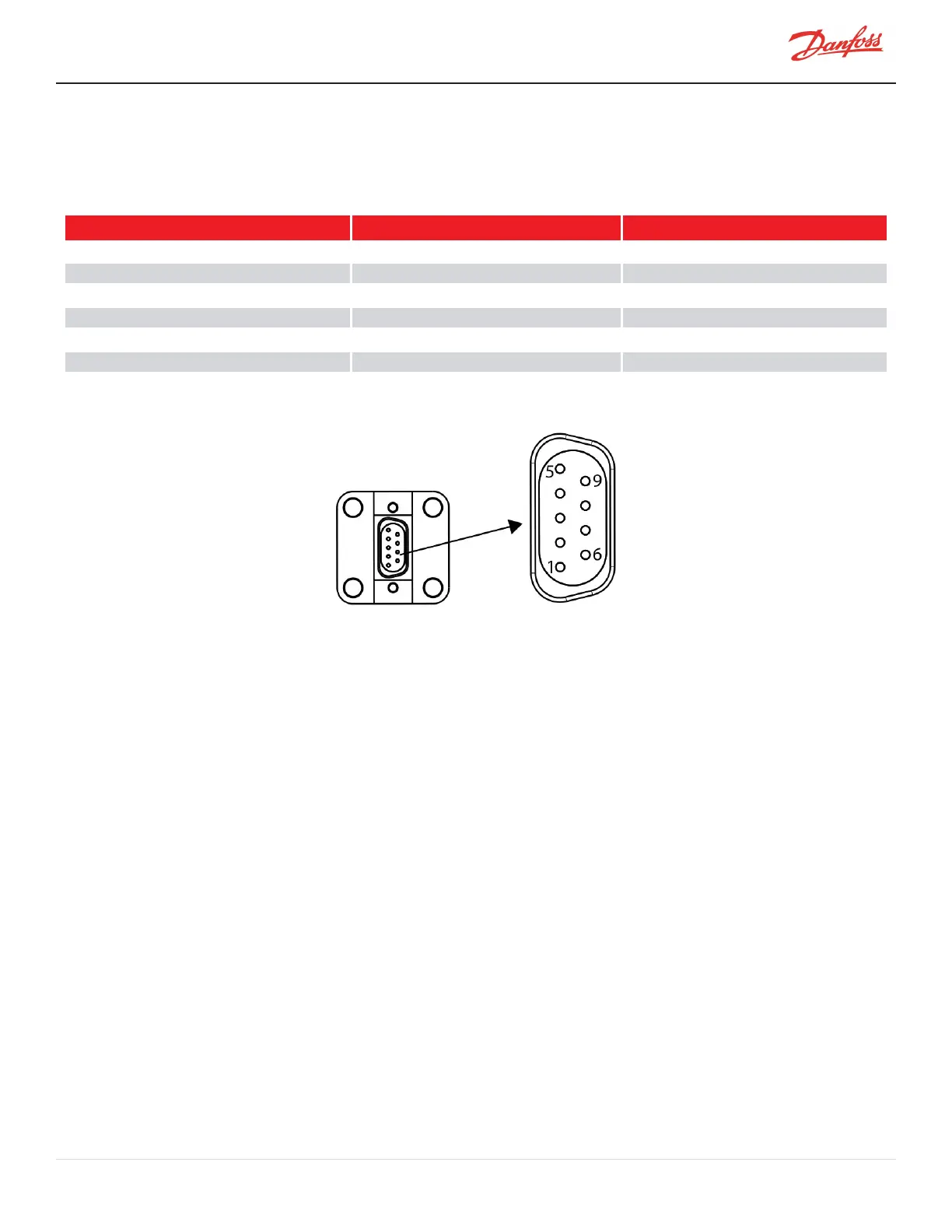

Table 4-48 Bearing Sensor Coil Resistance

Pin Combination Front Sensor Rear Sensor

5-2 2.0Ωto3.5Ω 2.0Ωto3.5Ω

5-3 2.0Ωto3.5Ω 2.0Ωto3.5Ω

6-7 2.0Ωto3.5Ω 2.0Ωto3.5Ω

6-8 2.0Ωto3.5Ω 2.0Ωto3.5Ω

1-4 2.0Ωto3.5Ω Open

1-9 2.0Ωto3.5Ω Open

Figure 4-263 Bearing Sensor Pin Locations

4.30.3.2 Bearing Sensor Cable Verification

Ifanyunexpectedbehaviorexists,itcouldbetheresultofanintermittentconnection.Ifnotproperlydiagnosed,the

issuemayleadtounnecessarilyreplacingcomponentsinthebearingcontrolloop,suchastheBMCC,PWM,Bearing

PowerFeedthroughs,orBearingSensorCables.

Thissectionprovidesverificationdetailsshouldacompressorexperienceabearingfaulttypewhereother

verification,testing,andtroubleshootingprocesseshavenotbeenabletoidentifythecause.

1. RemovetheModbusandInterlockconnectionsfromthecompressorI/OBoard.

2. ConnecttothecompressorusingtheSMTsoftwareandopentheCalibrationTool.

3. Performabearingcalibrationbyclickingon“StartCalibration.”

4. Aftercalibrationiscomplete,reviewthedata.Doallorbitsandgainvaluesappearnormal?

a. Yes:ContinuetoStep5.

b. No:ContinuetoStep7.

5. Performavalidationbyclickingon“Validate.”

6. Aftervalidationiscomplete,didtheshaftlevitateasexpected?

a. Yes:ContinuetoStep21.

b. No:ContinuetoStep7.

7. Isolatecompressorpower.

8. RemovetheServiceSideCover.RefertoSection4.1.3.1ServiceSideCoverRemovalandInstallationon

page54.

9. DisconnecttheBearingSensorCablesfromJ9andJ10attheBackplane.

M-SV-001-EN Rev. H-1/23/2023 Page 237 of 294

Loading...

Loading...