VLT

®

5000 FLUX

All about FCD

300

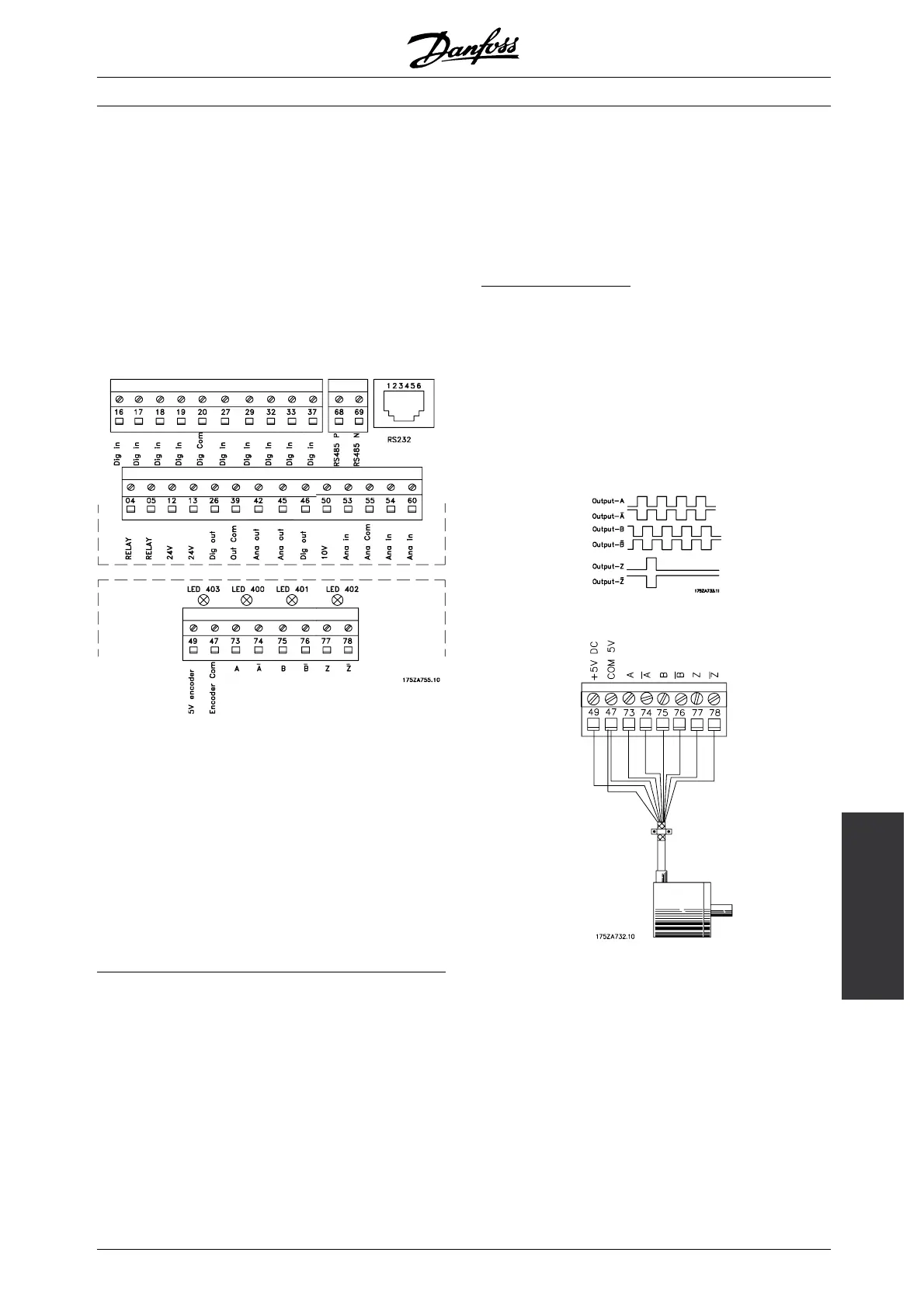

Terminal 37 is a "Hardware Coast" input function

for disabling the output stages (inverter). Terminal

37 cannot be disabled, handled or adjusted by

any parameters. Terminal 37 must be pulled up

to 24 V DC for the unit to work.

Installation of Control Cables

Tightening-up torque: 0.22 - 0.25 Nm

Screw size: M2

Screw driver type: 0.4 x 2.5 x 80 mm

See Earthing of Braided Screened/Armoured

Control Cables for correct earthing.

LEDs on encoder board:

When all LEDs are ON the connection to encoder

and encoder condition are OK.

LED 403 OFF: 5 V supply missing

LED 400 OFF: Channel A or inv. A missing

or shortcircuited

LED 401 OFF: Channel B or inv. B missing

or shortcircuited

LED 402 OFF: Channel Z or inv. Z missing

or shortcircuited.

■ Feedback System

The feedback system is necessary when the drive is

set to closed loop operation (Parameter 100 [1] or [5] ).

The VLT 5000 Flux accepts incremental encoders

as feedback system from motor.

C

onnection of encoder

VLT 5000 Flux supports most types of 4 channel + zero

pulse incremental encoders as feedback device.

Power

supply

5 V DC max 250 mA

(Encoder power consumption max

0.75 watt).

Max cable

length

(according to RS422 spec) < 150 m

If longer cables are used, please

contact Danfoss Drives.

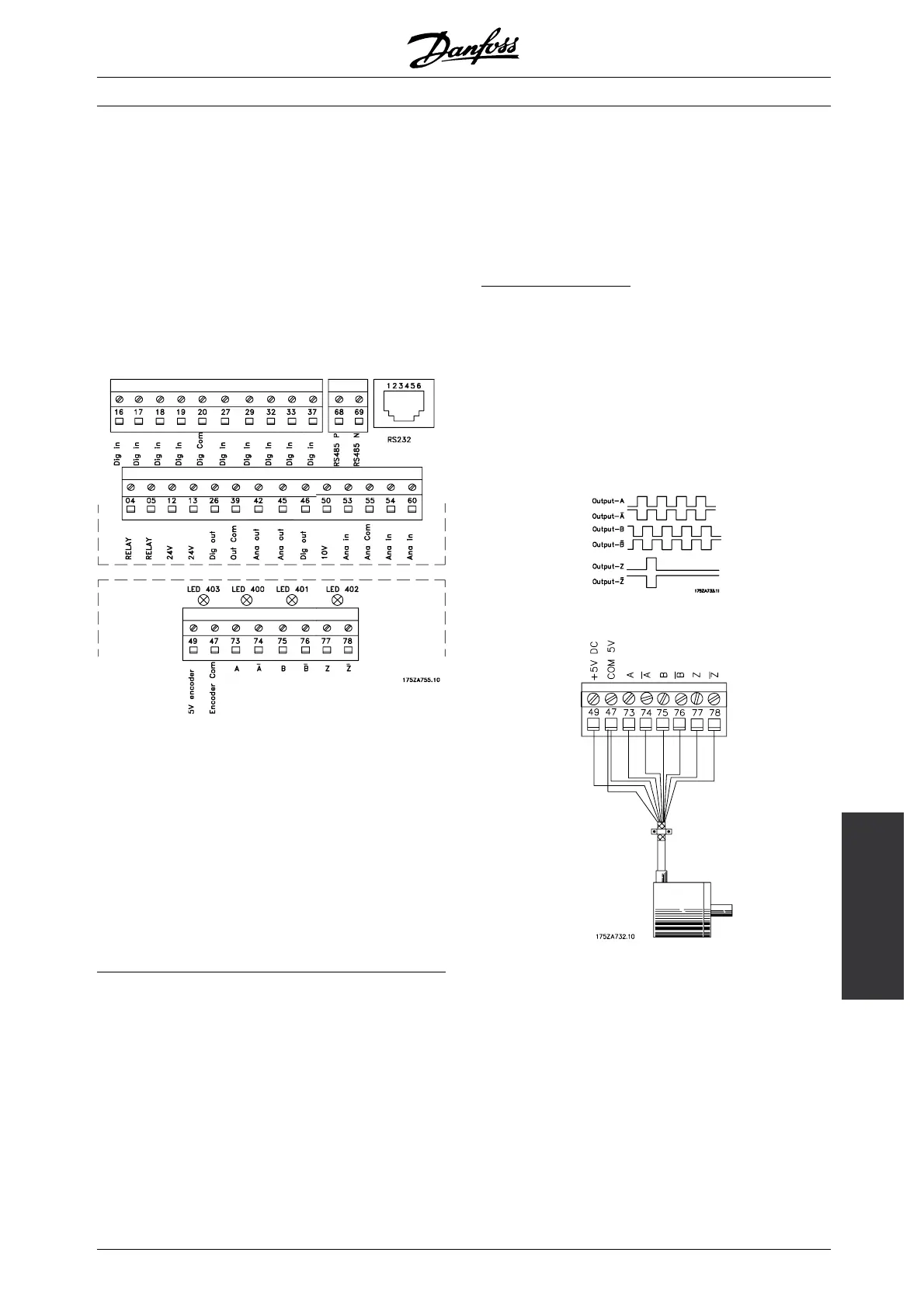

Typical impulse pattern from an incremental encoder

Basic encoder connection

MG.55.A6.02 - VLT is a registered Danfoss trademark

33

Loading...

Loading...