•

Do not ground one frequency converter to another

in a “daisy chain” fashion

•

Keep the ground wire connections as short as

possible

•

Use of high-strand wire to reduce electrical noise is

recommended

•

Follow motor manufacturer wiring requirements

2.4.2.1 Leakage Current (>3,5mA)

Follow national and local codes regarding protective

earthing of equipment with a leakage current > 3,5mA.

Frequency converter technology implies high frequency

switching at high power. This will generate a leakage current

in the earth connection. A fault current in the frequency

converter at the output power terminals might contain a DC

component which can charge the filter capacitors and cause

a transient earth current. The earth leakage current depends

on various system configurations including RFI filtering,

screened motor cables, and frequency converter power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3,5mA.

Earth grounding must be reinforced in one of the following

ways:

•

Earth ground wire of at least 10mm

2

•

Two separate earth ground wires both complying

with the dimensioning rules

See EN 60364-5-54 § 543.7 for further information.

Using RCDs

Where residual current devices (RCDs), also known as earth

leakage circuit breakers (ELCBs), are used, comply with the

following:

Use RCDs of type B only which are capable of

detecting AC and DC currents

Use RCDs with an inrush delay to prevent faults

due to transient earth currents

Dimension RCDs according to the system configu-

ration and environmental considerations

2.4.2.2 Grounding Using Shielded Cable

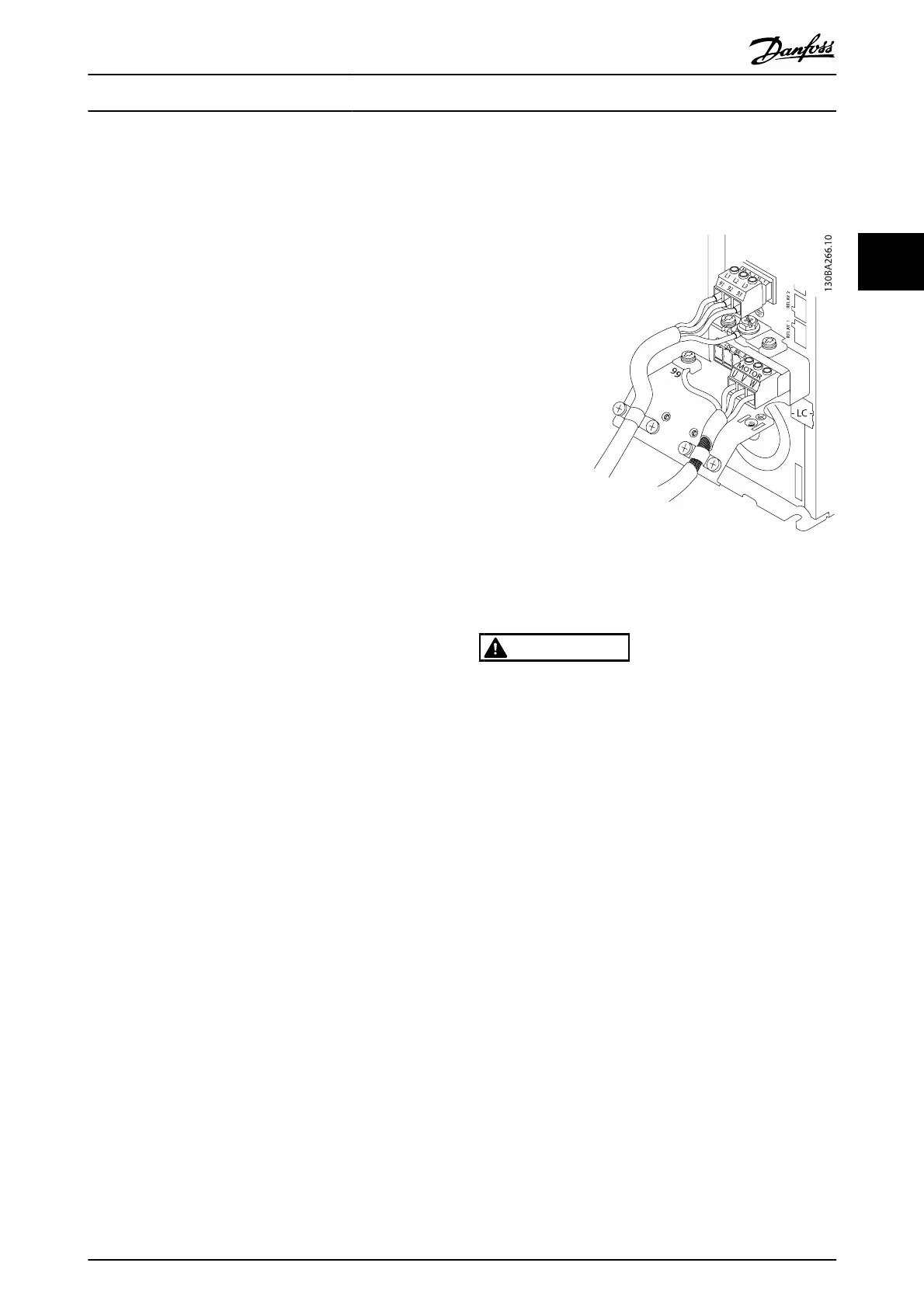

Earthing (grounding) clamps are provided for motor wiring

(see Illustration 2.7).

Illustration 2.7 Grounding with Shielded Cable

2.4.3 Motor Connection

WARNING

INDUCED VOLTAGE!

Run output motor cables from multiple frequency converters

separately. Induced voltage from output motor cables run

together can charge equipment capacitors even with the

equipment turned off and locked out. Failure to run output

motor cables separately could result in death or serious

injury.

•

For maximum wire sizes see 10.1 Power-dependent

Specifications

•

Comply with local and national electrical codes for

cable sizes

•

Motor wiring knockouts or access panels are

provided at the base of IP21 and higher

(NEMA1/12) units

•

Do not install power factor correction capacitors

between the frequency converter and the motor

•

Do not wire a starting or pole-changing device

between the frequency converter and the motor

•

Connect the 3-phase motor wiring to terminals 96

(U), 97 (V), and 98 (W)

•

Ground the cable in accordance with grounding

instructions provided

•

Torque terminals in accordance with the

information provided in 10.4.1 Connection

Tightening Torques

Installation

VLT

®

AutomationDrive Operating

Instructions

MG.33.AJ.02 - VLT

®

is a registered Danfoss trademark 13

2

Loading...

Loading...