3.5 Check Motor Rotation

Prior to running the frequency converter, check the motor

rotation.

1. Press [Hands on].

2. Press [►] for positive speed reference.

3. Check that the speed displayed is positive.

When 1-06 Clockwise Direction is set to [0]* Normal (default

clockwise):

4a. Verify that the motor turns clockwise.

5a. Verify that the LCP direction arrow is clockwise.

When 1-06 Clockwise Direction is set to [1] Inverse (counter-

clockwise):

4b. Verify that the motor turns counter-clockwise.

5b. Verify that the LCP direction arrow is counter-

clockwise.

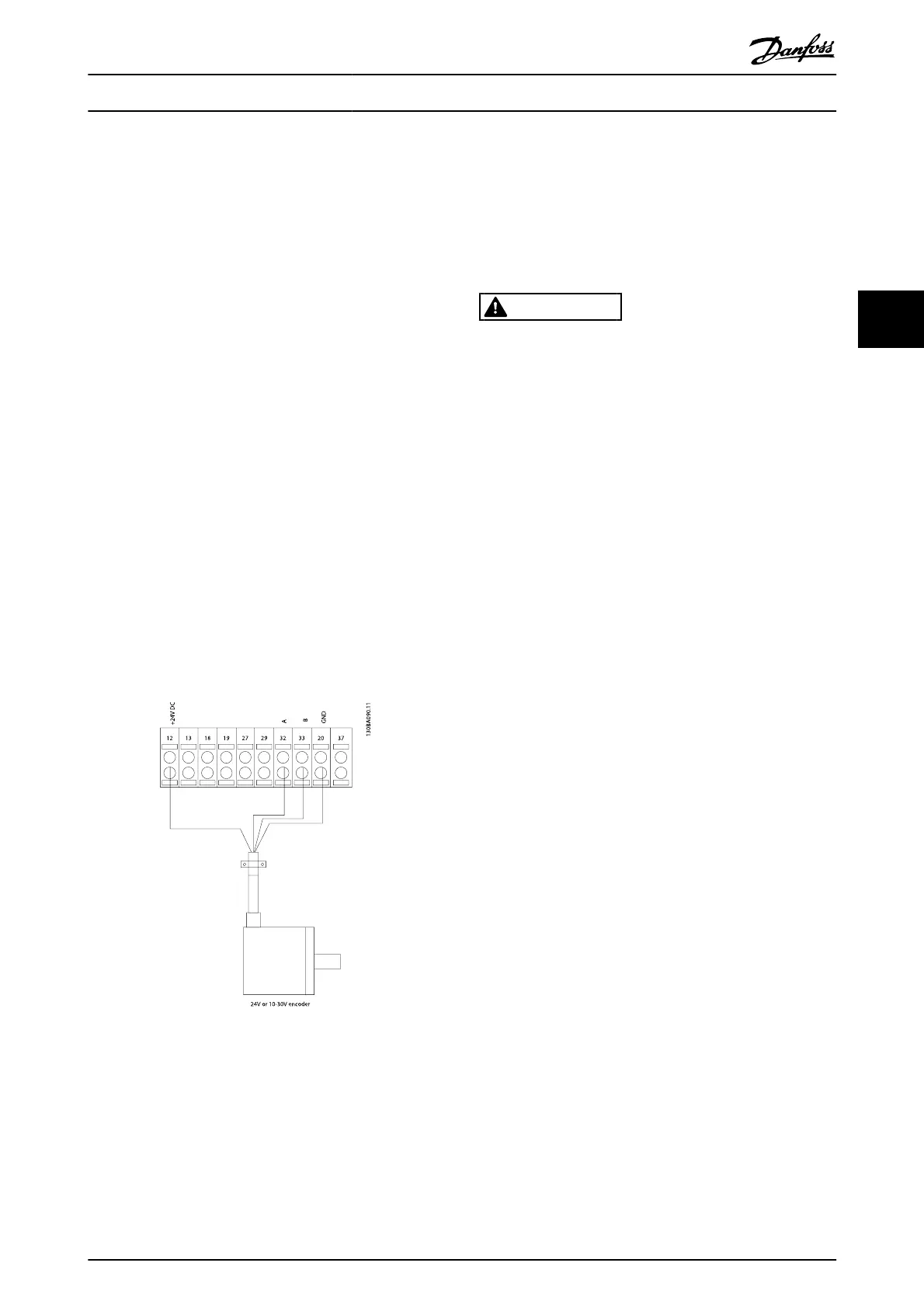

3.6 Check Encoder Rotation

Check encoder rotation only if encoder feedback is used.

Check encoder rotation in default open loop control.

1. Verify that the encoder connection is according to

the wiring diagram:

NOTE

When using an encoder option, refer to the option manual

2. Enter the Speed PID feed-back source in 7-00 Speed

PID Feedback Source.

3. Press [Hand On]

4.

Press [►] for positive speed reference

(1-06 Clockwise Direction at [0]* Normal).

5. Check in 16-57 Feedback [RPM] that the feed-back is

positive

NOTE

If the feedback is negative, the encoder connection is wrong!

3.7 Local-control Test

CAUTION

MOTOR START!

Ensure that the motor, system, and any attached equipment

is ready for start. It is the responsibility of the user to ensure

safe operation under any operational condition. Failure to

ensure that the motor, system, and any attached equipment

is ready for start could result in personal injury or equipment

damage.

NOTE

The hand on key on the LCP provides a local start command

to the frequency converter. The OFF key provides the stop

function.

When operating in local mode, the up and down arrows on

the LCP increase and decrease the speed output of the

frequency converter. The left and right arrow keys move the

display cursor in the numeric display.

1. Press [Hand On].

2.

Accelerate the frequency converter by pressing [

▲

]

to full speed. Moving the cursor left of the decimal

point provides quicker input changes.

3. Note any acceleration problems.

4. Press [OFF].

5. Note any deceleration problems.

If acceleration problems were encountered

•

If warnings or alarms occur, see 8 Warnings and

Alarms

•

Check that motor data is entered correctly

•

Increase the ramp-up time in 3-41 Ramp 1 Ramp Up

Time

•

Increase current limit in 4-18 Current Limit

•

Increase torque limit in 4-16 Torque Limit Motor

Mode

If deceleration problems were encountered

•

If warnings or alarms occur, see 8 Warnings and

Alarms

•

Check that motor data is entered correctly

•

Increase the ramp-down time in 3-42 Ramp 1 Ramp

Down Time

Start Up and Functional Tes...

VLT

®

AutomationDrive Operating

Instructions

MG.33.AJ.02 - VLT

®

is a registered Danfoss trademark 25

3

Loading...

Loading...