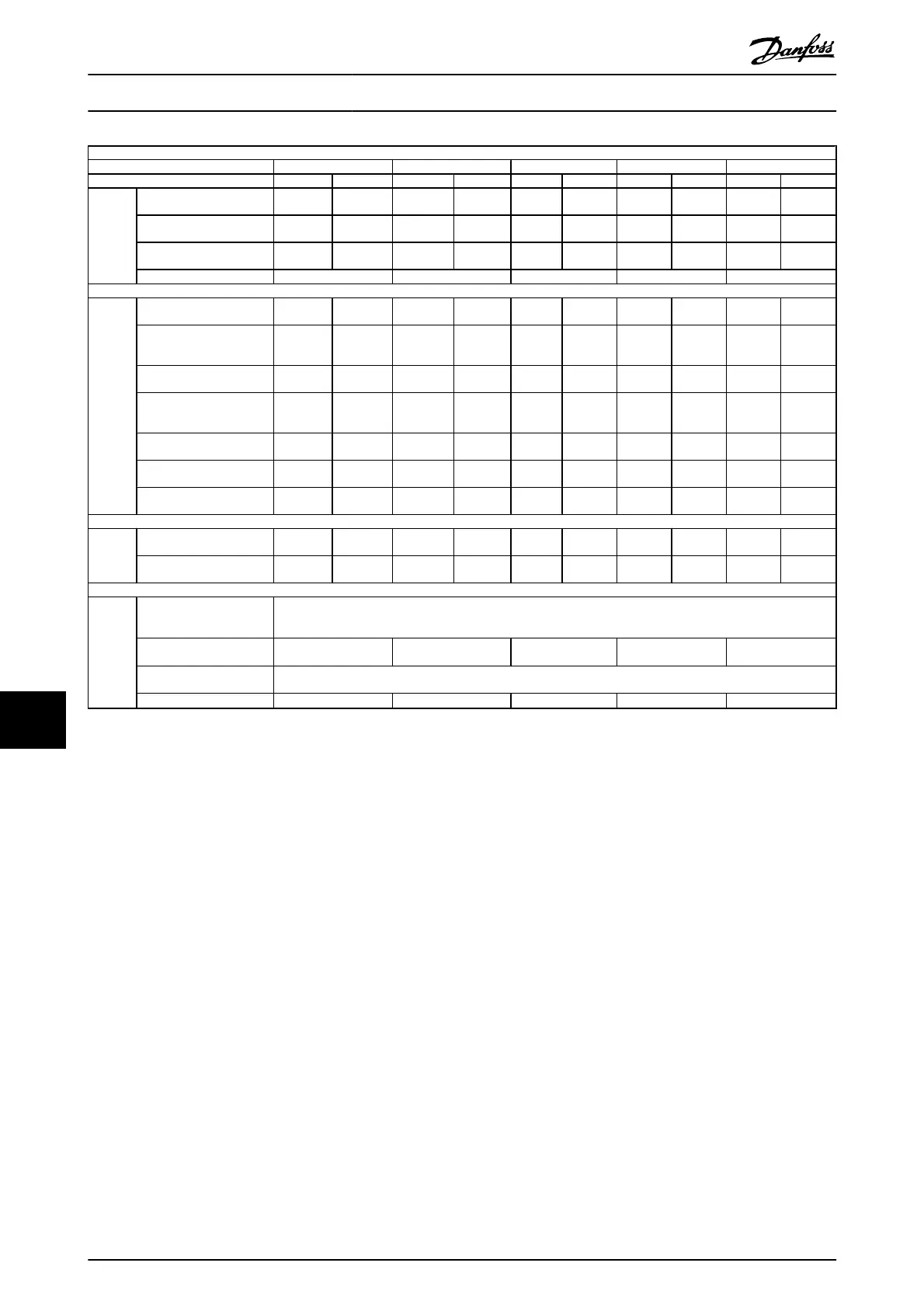

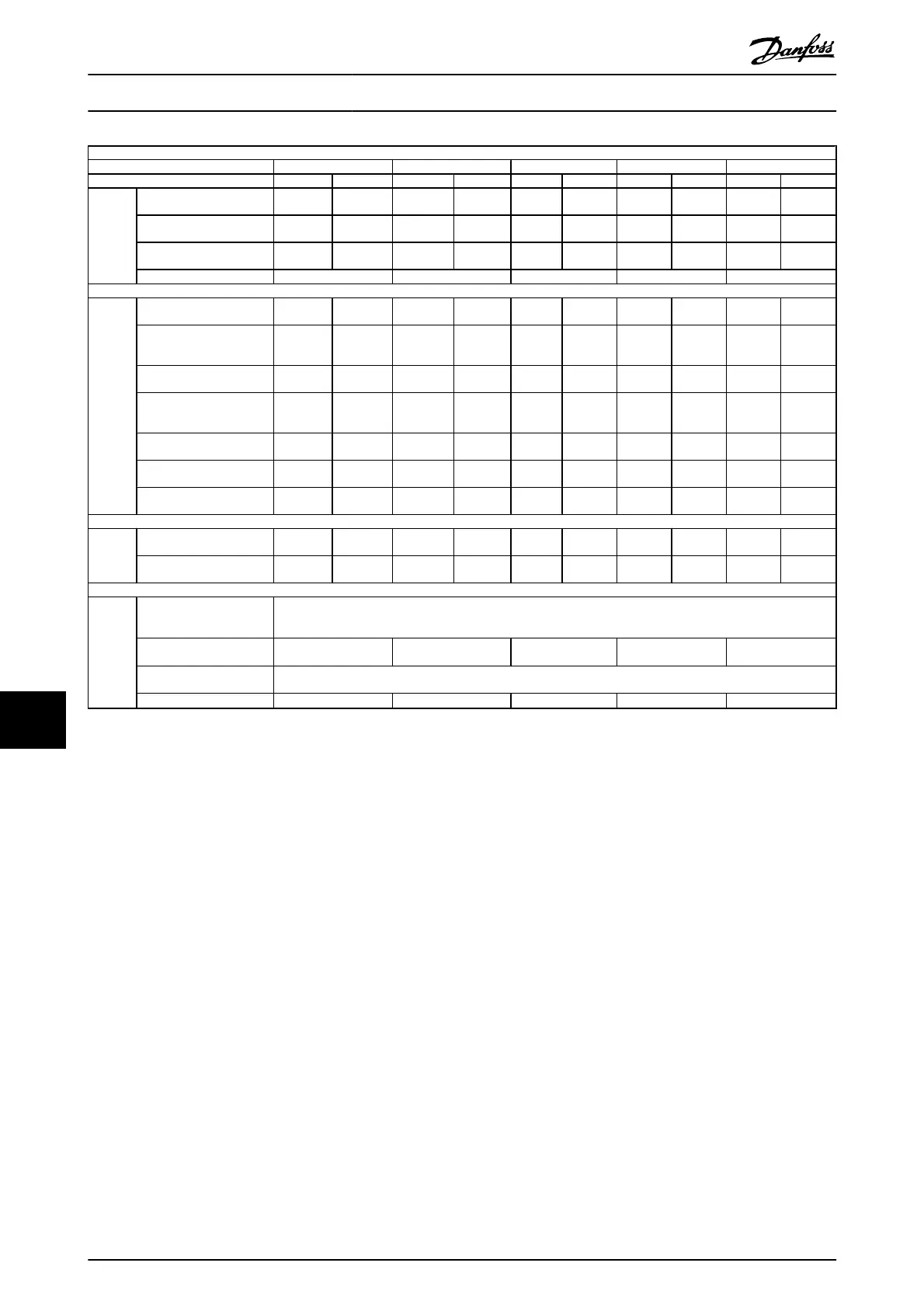

Mains Supply 3 x 525- 690V AC

FC 302 P30K P37K P45K P55K P75K

High/ Normal Load* HO NO HO NO HO NO HO NO HO NO

Typical Shaft output at 550V

[kW]

22 30 30 37 37 45 45 55 55 75

Typical Shaft output at 575V

[HP]

30 40 40 50 50 60 60 75 75 100

Typical Shaft output at 690V

[kW]

30 37 37 45 45 55 55 75 75 90

Enclosure IP21, 55 C2 C2 C2 C2 C2

Output current

Continuous

(3 x 525-550V) [A]

36 43 43 54 54 65 65 87 87 105

Intermittent (60 sec

overload)

(3 x 525-550V) [A]

54 47.3 64.5 59.4 81 71.5 97.5 95.7 130.5 115.5

Continuous

(3 x 551-690V) [A]

34 41 41 52 52 62 62 83 83 100

Intermittent (60 sec

overload)

(3 x 551-690V) [A]

51 45.1 61.5 57.2 78 68.2 93 91.3 124.5 110

Continuous KVA

(at 550V) [KVA]

34.3 41.0 41.0 51.4 51.4 61.9 61.9 82.9 82.9 100.0

Continuous KVA

(at 575V) [KVA]

33.9 40.8 40.8 51.8 51.8 61.7 61.7 82.7 82.7 99.6

Continuous KVA

(at 690V) [KVA]

40.6 49.0 49.0 62.1 62.1 74.1 74.1 99.2 99.2 119.5

Max. input current

Continuous

(at 550V) [A]

36 49 49 59 59 71 71 87 87 99

Continuous

(at 575V) [A]

54 53.9 72 64.9 87 78.1 105 95.7 129 108.9

Additional specifications

Max. cable size, mains,

motor, load share and brake

[mm

2

(AWG)]

95 (4/0)

Estimated power loss

at rated max. load [W]

4)

480 592 720 880 1200

Weight,

enclosure IP21, IP55 [kg]

65

Efficiency

4)

0.98 0.98 0.98 0.98 0.98

For fuse ratings, see 10.3.1 Fuses

1) High overload = 160% torque during 60 sec., Normal overload = 110% torque during 60 sec.

2) American Wire Gauge.

3) Measured using 5 m screened motor cables at rated load and rated frequency.

4) The typical power loss is at nominal load conditions and expected to be within +/-15% (tolerence relates to variety

in voltage and cable conditions).

Values are based on a typical motor efficiency (eff2/eff3 border line). Motors with lower efficiency will also add to the

power loss in the frequency converter and opposite.

If the switching frequency is increased compared to the default setting, the power losses may rise significantly.

LCP and typical control card power consumptions are included. Further options and customer load may add up to 30W

to the losses. (Though typical only 4W extra for a fully loaded control card, or options for slot A or slot B, each).

Although measurements are made with state of the art equipment, some measurement inaccuracy must be allowed

for (+/-5%).

Specifications

VLT

®

AutomationDrive Operating

Instructions

70 MG.33.AJ.02 - VLT

®

is a registered Danfoss trademark

100

Loading...

Loading...