11.11.5 Conversion Factor

The different attributes for each parameter can be seen in

the section on factory settings. Since a parameter value

can only be transferred as a whole number, a conversion

factor must be used to transfer decimals. Please refer to

the Parameters section.

11.11.6 Parameter Values

Standard Data Types

Standard data types are int16, int32, uint8, uint16 and

uint32. They are stored as 4x registers (40001 – 4FFFF). The

parameters are read using function 03HEX "Read Holding

Registers." Parameters are written using the function 6HEX

"Preset Single Register" for 1 register (16 bits), and the

function 10HEX "Preset Multiple Registers" for 2 registers

(32 bits). Readable sizes range from 1 register (16 bits) up

to 10 registers (20 characters).

Non standard Data Types

Non standard data types are text strings and are stored as

4x registers (40001 – 4FFFF). The parameters are read

using function 03HEX "Read Holding Registers" and written

using function 10HEX "Preset Multiple Registers." Readable

sizes range from 1 register (2 characters) up to 10 registers

(20 characters).

11.12

Danfoss FC Control Profile

11.12.1 Control Word According to FC

Profile (8-10 Control Profile = FC

profile)

Speed ref.CTW

Master-slave

130BA274.10

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

no.:

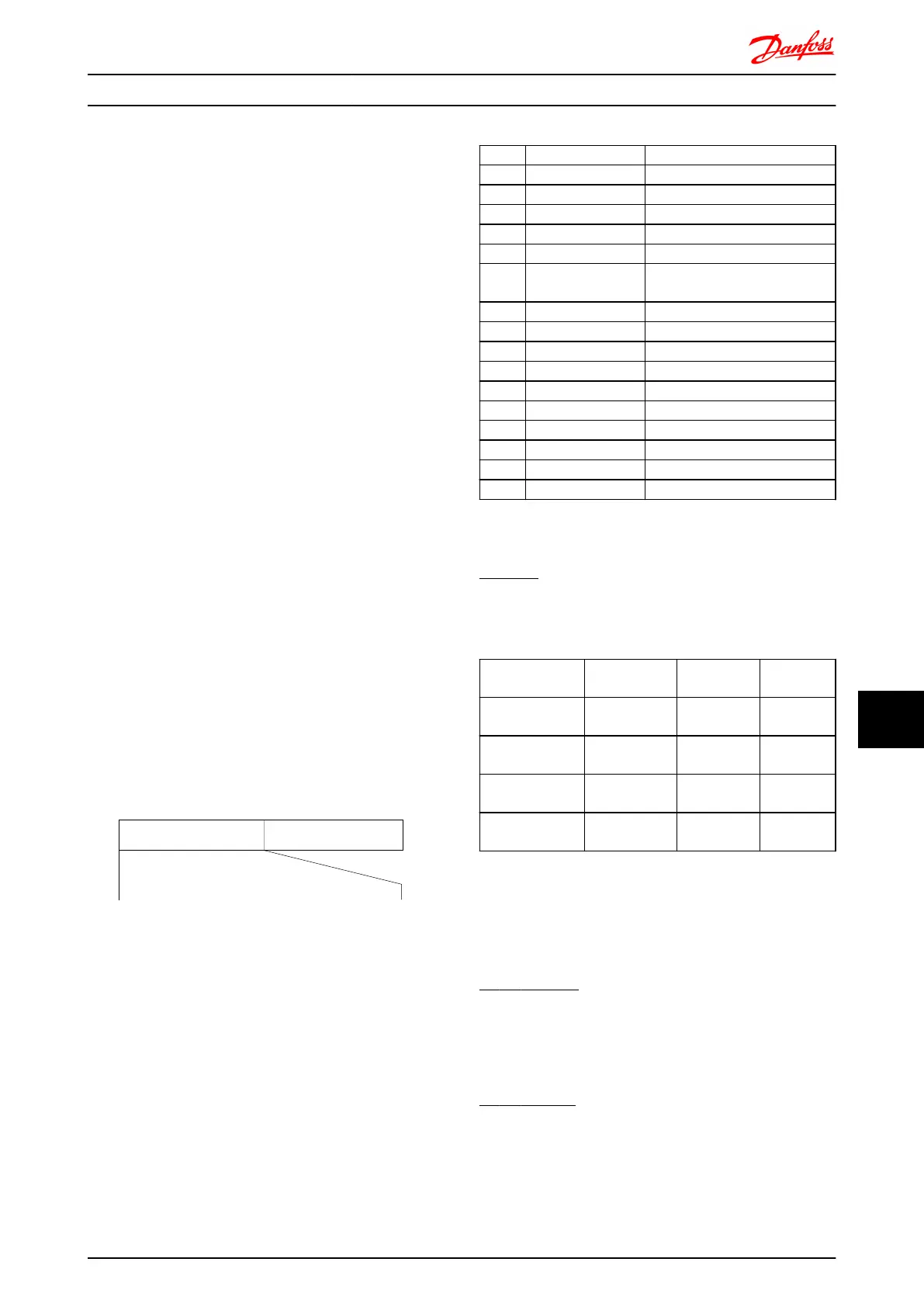

Bit Bit value = 0 Bit value = 1

00 Reference value external selection lsb

01 Reference value external selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output

frequency

use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 02 active

13 Parameter set-up selection lsb

14 Parameter set-up selection msb

15 No function Reverse

Explanation of the Control Bits

Bits 00/01

Bits 00 and 01 are used to choose between the four

reference values, which are pre-programmed in 3-10 Preset

Reference according to the following table:

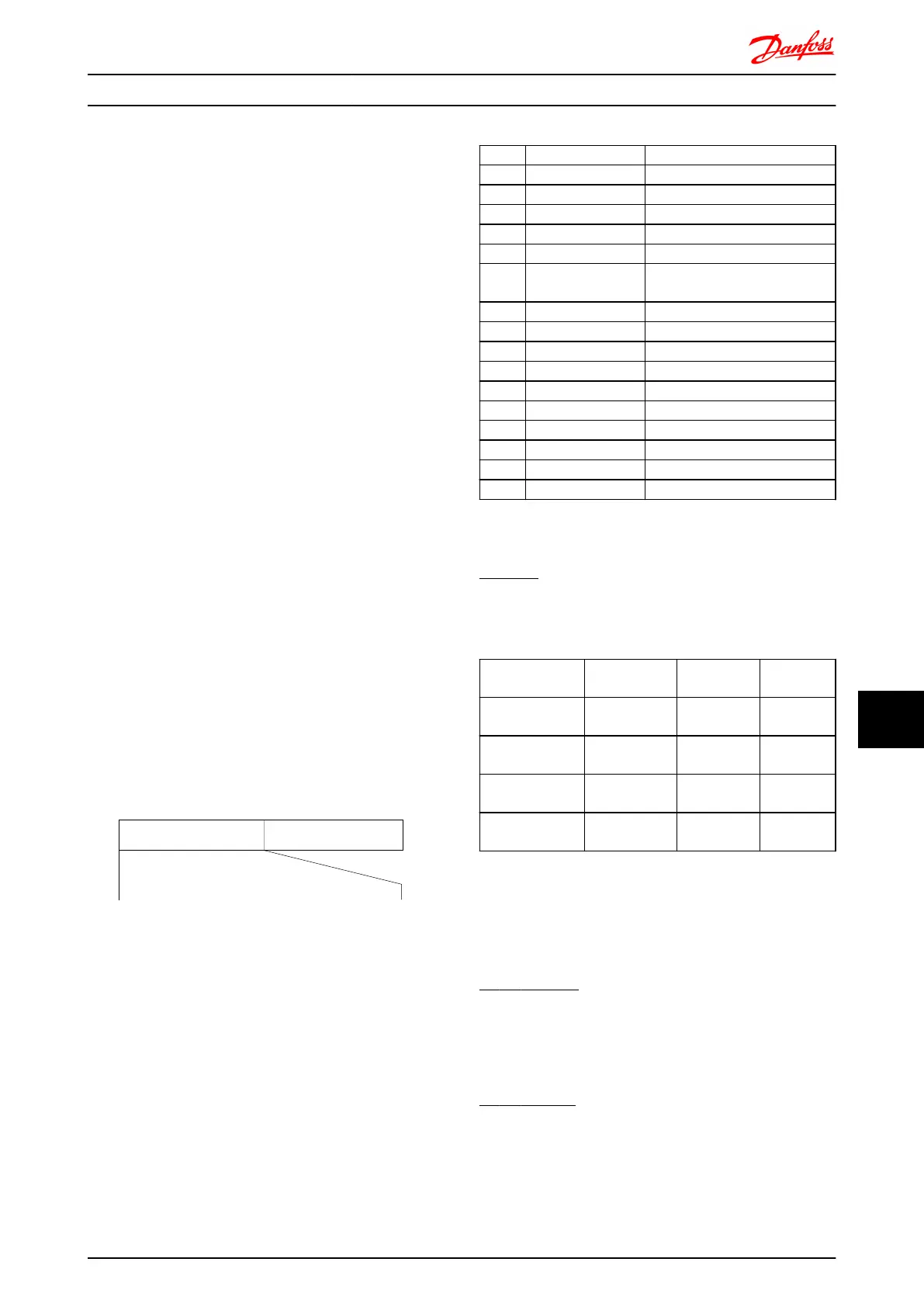

Programmed ref.

value

Parameter Bit 01 Bit 00

1

3-10 Preset

Reference [0]

0 0

2

3-10 Preset

Reference [1]

0 1

3

3-10 Preset

Reference [2]

1 0

4

3-10 Preset

Reference [3]

1 1

NOTE

Make a selection in 8-56 Preset Reference Select to define

how Bit 00/01 gates with the corresponding function on

the digital inputs.

Bit 02, DC brake:

Bit 02 = ’0’ leads to DC braking and stop. Set braking

current and duration in 2-01 DC Brake Current and 2-02 DC

Braking Time. Bit 02 = ’1’ leads to ramping.

Bit 03, Coasting:

Bit 03 = ’0’: The frequency converter immediately "lets go"

of the motor, (the output transistors are "shut off") and it

coasts to a standstill. Bit 03 = ’1’: The frequency converter

starts the motor if the other starting conditions are met.

RS-485 Installation and Set... FC 300 Design Guide

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark 267

11

11

Loading...

Loading...