Parking

This function is the recommended choice for applications

where the motor is rotating at slow speed, e.g., windmilling

in fan applications. 2-06 Parking Current and 2-07 Parking

Time can be adjusted. Increase the factory setting of these

parameters for applications with high inertia.

Start the motor at nominal speed. If the application does not

run well, check the VVC

plus

PM settings. Recommendations in

different applications can be seen in Table 5.6.

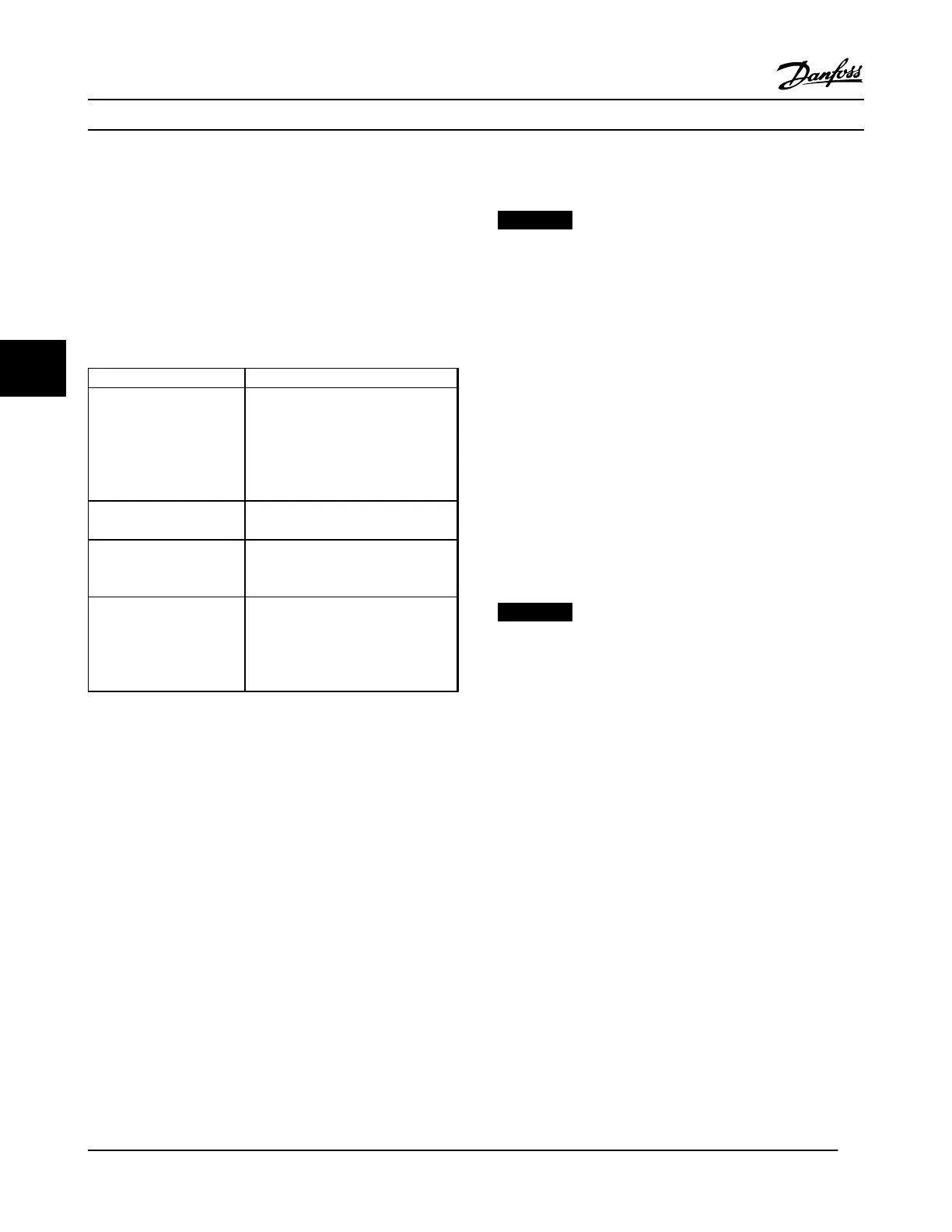

Application Settings

Low inertia applications

I

Load

/I

Motor

<5

1-17 Voltage filter time const. to be

increased by factor 5 to 10

1-14 Damping Gain should be

reduced

1-66 Min. Current at Low Speed should

be reduced (<100%)

Low inertia applications

50>I

Load

/I

Motor

>5

Keep calculated values

High inertia applications

I

Load

/I

Motor

> 50

1-14 Damping Gain, 1-15 Low Speed

Filter Time Const. and 1-16 High Speed

Filter Time Const. should be increased

High load at low speed

<30% (rated speed)

1-17 Voltage filter time const. should

be increased

1-66 Min. Current at Low Speed should

be increased (>100% for a prolonged

time can overheat the motor)

Table 5.6 Recommendations for Different Applications

If the motor starts oscillating at a certain speed, increase

1-14 Damping Gain. Increase the value in small steps.

Depending on the motor, a good value for this parameter

can be 10% or 100% higher than the default value.

Starting torque can be adjusted in 1-66 Min. Current at Low

Speed. 100% provides nominal torque as starting torque.

5.4.5

Automatic Energy Optimization (AEO)

NOTICE!

AEO is not relevant for permanent magnet motors.

Automatic Energy Optimization (AEO) is recommended for

•

Automatic compensation for oversized motors

•

Automatic compensation for slow system load

change

•

Automatic compensation for seasonal changes

•

Automatic compensation for low motor loading

•

Reduced energy consumption

•

Reduced motor heating

•

Reduced motor noise

To activate AEO, set parameter 1-03 Torque Characteristics to

[2] Auto Energy Optim. CT or [3] Auto Energy Optim. VT.

5.4.6

Automatic Motor Adaptation (AMA)

NOTICE!

AMA is not relevant for permanent magnet motors.

Automatic motor adaptation (AMA) is a procedure that

optimizes compatibility between the adjustable frequency

drive and the motor.

•

The adjustable frequency drive builds a

mathematical model of the motor for regulating

output motor current. The procedure also tests the

input phase balance of electrical power. It compares

the motor characteristics with the data entered in

parameters 1-20 to 1-25

•

The motor shaft does not turn and no harm is done

to the motor while running the AMA.

•

Some motors may be unable to run the complete

version of the test. In that case, select [2] Enable

reduced AMA.

•

If an output filter is connected to the motor, select

Enable reduced AMA.

•

If warnings or alarms occur, see 7.3 List of Warnings

and Alarms.

•

Run this procedure on a cold motor for best results.

Commissioning

VLT

®

HVAC Drive Instruction Manual

30 MG11AJ22 - Rev. 2013-09-13

55

Loading...

Loading...