Appendix - User info codes_02/2017 - 29 -

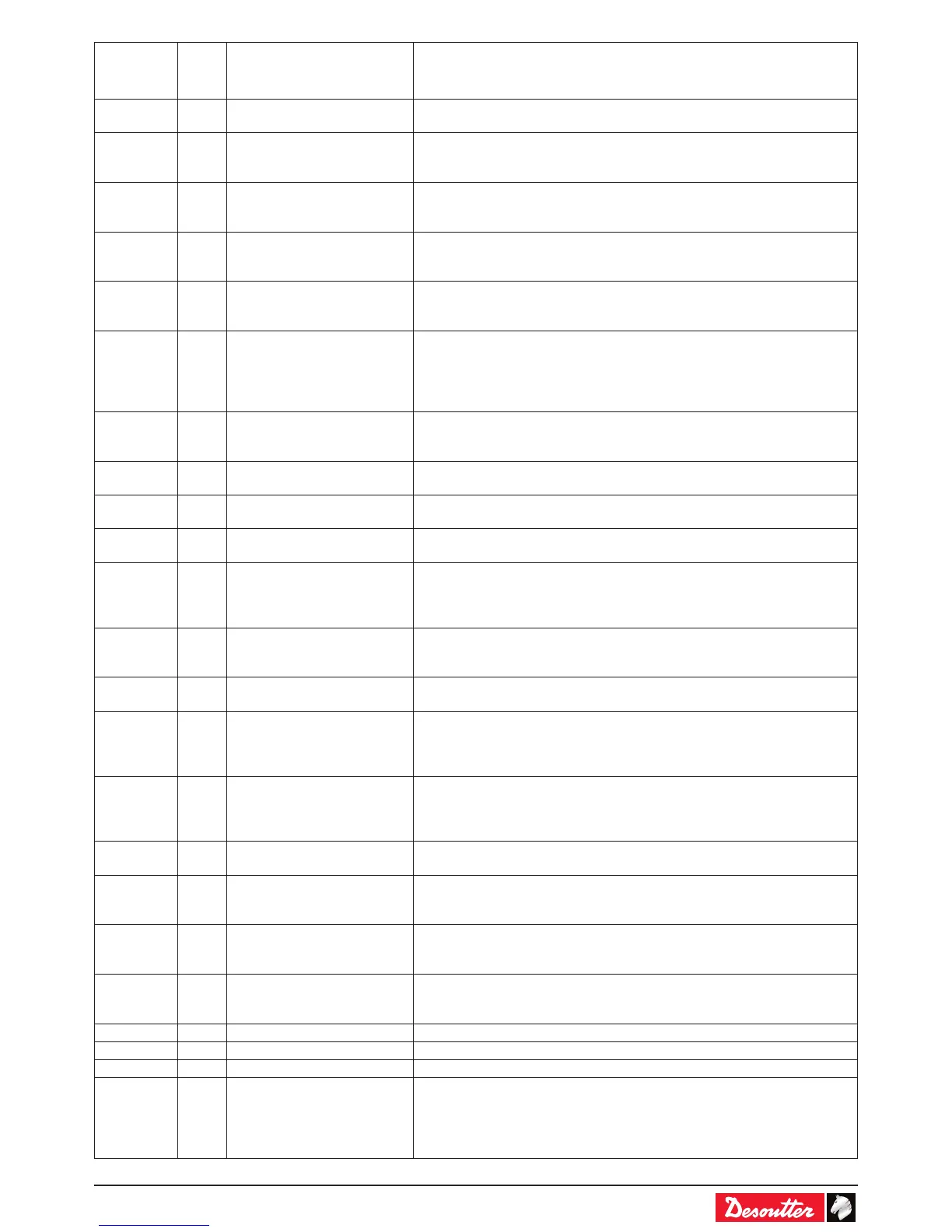

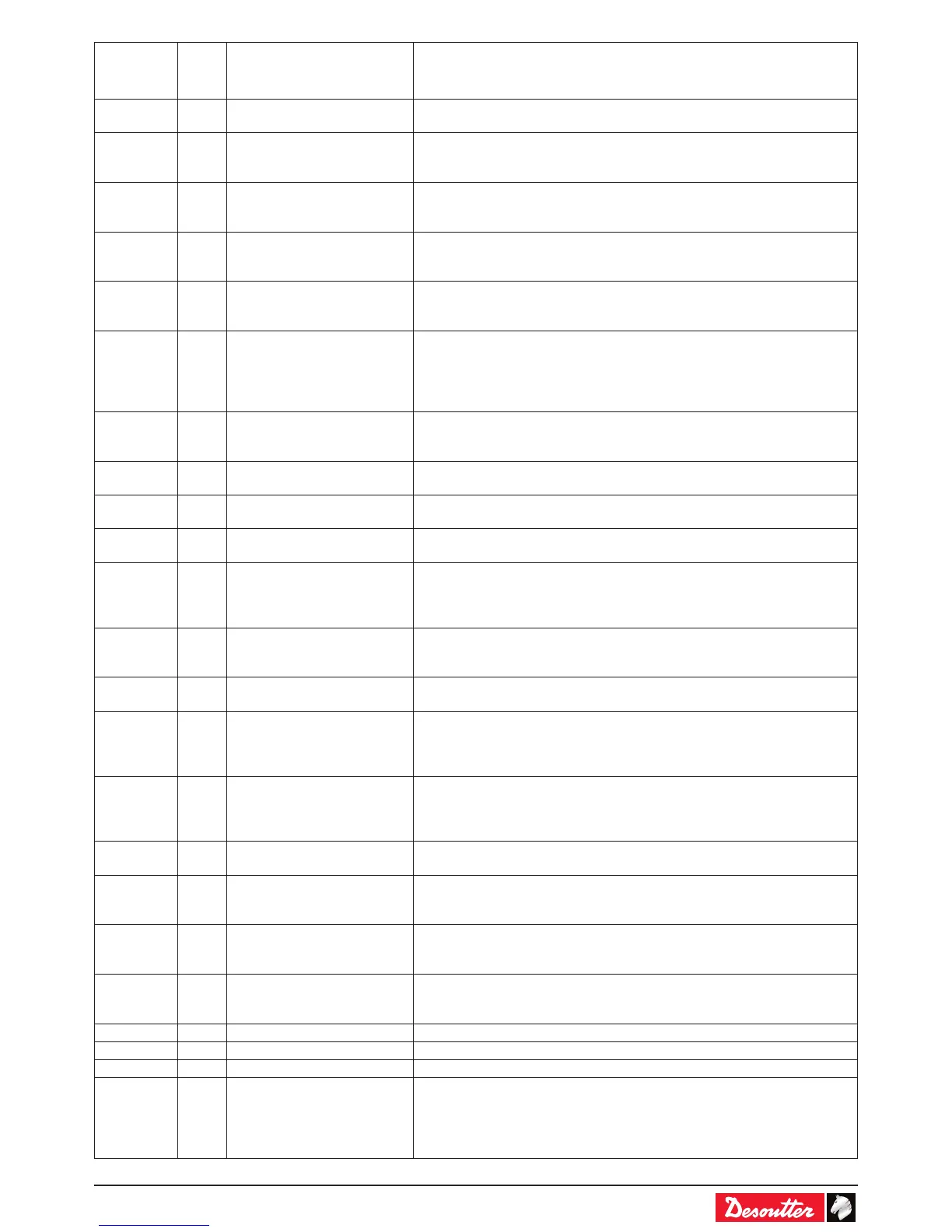

Type of

code

Code

no.

Description Resolution procedure

Info 61 ExBC connection conict 1- 2 ExBC are congured with the same network settings

2- Verify communication ports and IP addresses

Info 100 Cable id invalid param 1- Invalid tool cable parameter, check that the tool cable is Desoutter

certied

2- Contact your Desoutter representative for support

Info 101 Cable id not detected 1- Tool cable communication error, check that the tool cable is Desoutter

certied

2- Contact your Desoutter representative for support

Info 102 Cable id not certif 1- Tool cable authentication error, check that the tool cable is Desoutter

certied

2- Contact your Desoutter representative for support

Info 199 Console activated 1- The serial console is activated.

2- Warning, this console is dedicated only to debug purposes and should

not be used in production

Info 202 Fieldbus lost 1- Fieldbus connection with PLC is lost.

- no heartbeat is received from PLC

- the cable is broken or disconnected

- the PLC is off line or not powered

2- Check the Fieldbus conguration.

Info 204 Tool not validated 1- Tool locked by I/O.

2- Check the I/O settings: the "Tool validation" must be active to unlock the

tool.

Info 205 Torque settings 1-Invalid Torque setting, torque is greater than tool characteristics

2-Check Pset settings with the current tool characteristics

Info 206 Speed settings 1-Invalid speed setting, speed is greater than tool characteristics

2-Check Pset settings with the tool max. speed.

Info 207 Assembly done 1- Assembly Process is done, the tool is locked

2- Select new Assembly Process to unlock the tool

Info 208 Invalid run reverse param 1-Invalid Run reverse setting, torque or speed are greater than tool

characteristics or reverse strategy is not supported

2-Check Pset settings with the current tool characteristics

3-Reduce max number of turns

Info 209 Pset invalid parameters 1 - Software internal error.

2 - Pset is corrupted. Try to transfer it again to the controller.

3 - If the error persists contact your Desoutter representative for support.

Info 210 Invalid Pset selected 1- The Pset currently selected does not match the selectable one in the

Assembly Process.

Info 211 Invalid trigger conf 1- The tool currently connected to the CVI3 is not equipped with the trigger

required by the tool trigger conguration

2- Adjust your tool trigger conguration to the tool connected or change the

tool according to the expected trigger conguration

Info 215 Current calib. err. 1- Current calibration failed.

2- Try once again.

3- If the problem occurs again, contact your Desoutter representative for

support.

Info 224 IGBT too hot 1- Power electronics too warm.

2- Let the controller cool down.

Info 225 Err. angle 1- Tool communication error.

2- Check tool and cable connections. If the problem occurs again, contact

your Desoutter representative for support.

Info 226 Err. torque 1- Tool communication error. Check tool and cable connections.

2- Try once again, if the problem occurs again, contact your Desoutter

representative for support.

Info 234 Fieldbus mismatch 1-The Fieldbus module declared in conguration is not the same that the

one present in controller (e.g. Probus declared but a Pronet module in

CVI3).

Info 237 Invalid data 1- The Fieldbus mapping has too many items.

Info 238 Invalid address 1- The device address affected to Fieldbus is invalid.

Info 239 Invalid com settings 1- Fieldbus communication settings are invalid

Info 241 CVINet FIFO alarm 1- The CVINet result FIFO has reached alarm threshold, the CVINet

connection has been lost

2- Check the CVI3 Ethernet cable

3- Check CVI3 Ethernet conguration

4- Check if CVINet is running correctly

Loading...

Loading...