21

2009 DURATECH TUB GRINDER OPERATING INSTRUCTIONS

2.3 Dry Clutch

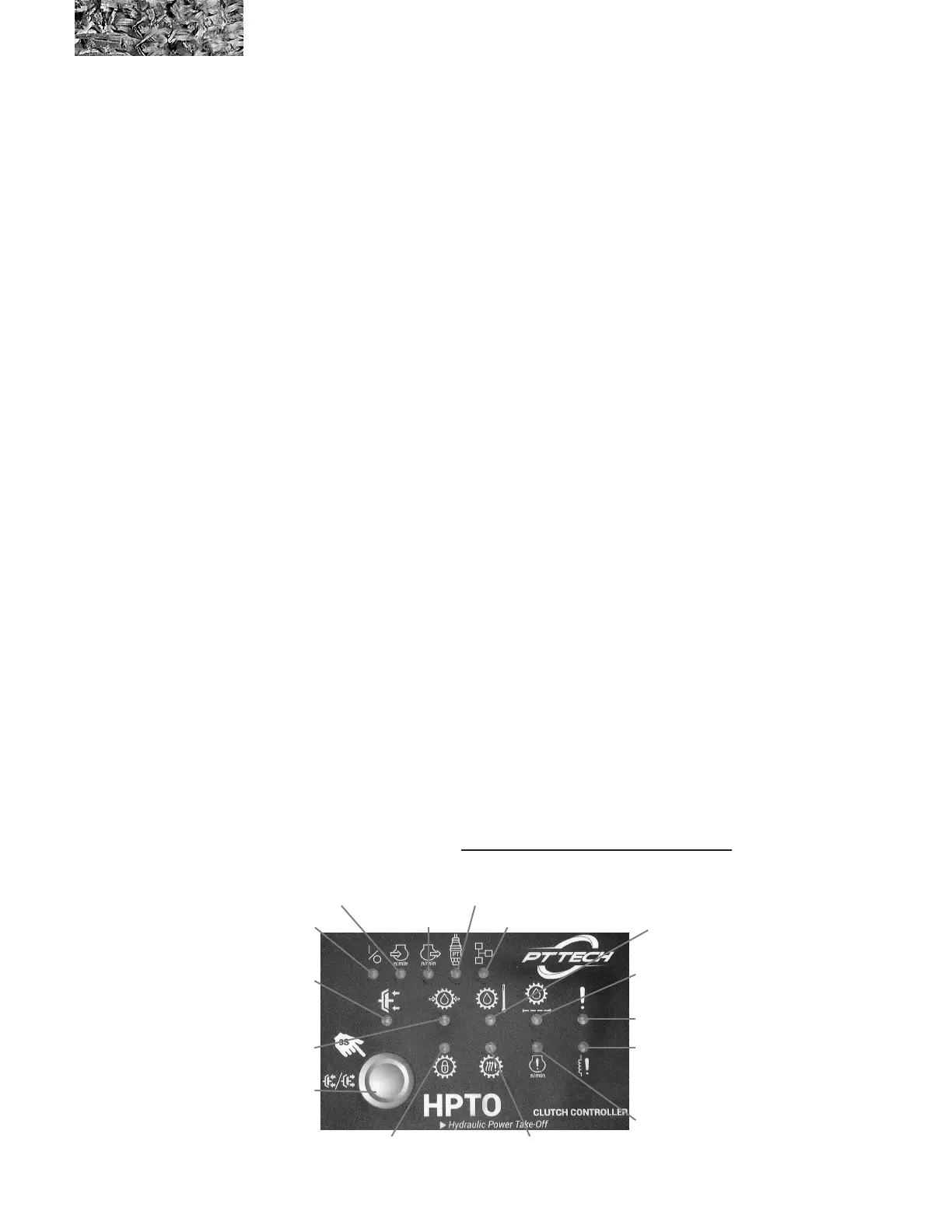

The HPTO™ Hydraulic Power Take-off is a hydraulically actuated, enclosed dry clutch that requires no adjustment

throughout its wear life. During a torque spike, the clutch will act as a torque limiter by slipping to absorb the

shockload. The bearings in the clutch are greased for the life of the product.

A Microprocessor Controller provides remote push button controlled clutch engagement of the HPTO. The controller

monitors clutch pressure, engine speed, and an equipment safety switch.

A Hydraulic Manifold Assembly controls the pressure required for clutch engagement. System components include a

DC coil, a pressure regulating cartridge, and a pressure switch.

The pre‑programmed setting of the controller determines how the HPTO unit will function during startup.

The “Power” LED illuminates to notify the operator that the controller is receiving switched power from the engine

ignition switch.

The “Engine RPM” LED illuminates when the engine is running.

To engage the clutch, set the engine rpm below 1100 rpm, press and hold the “Engage/Disengage Button” for 3

seconds. Once the “Clutch Engage Symbol” illuminates, the button can be released. The controller will begin the

engagement of the clutch and perform a series of “bumps” to bring the driven equipment up to engine speed.

Note that there is a safety switch that prevents the rotor from engaging when the tub platform is raised.

If the engine speed is above 1100 rpm while attempting to engage the clutch, the “Engine Over‑Speed Symbol” will

illuminate. Reduce engine speed below 1100 rpm and the light will turn off.

To disengage the clutch, set engine speed below 1200 rpm and push the “Engage/Disengage Button”. The clutch will

immediately disengage.

The controller will allow 3 failed clutch startup attempts in a row. After the 3

rd

failed clutch startup attempt, the

controller will prevent the clutch from being engaged for 10 minutes.

There are 3 different conditions that are considered as “failed start attempts”. They are:

- The engine speed goes to zero and the engine stalls while the clutch is engaging.

- The operator attempts to increase engine speed while the clutch is engaging.

‑ The operator pushes the green engage/disengage button to disengage the clutch while the clutch is engaging.

If there is a pressure loss while the clutch is engaged, the controller will disengage the clutch and the “Oil Pressure Loss

Symbol” will FLASH to indicate that there was as pressure loss while the clutch was engaged.

( REV. 9-17 )

Safety Switch

Coil Fault

RPM Too High

Filter Clogged

Oil Temperature

Clutch Overload

Timed Lockout

Engage / Disengage Button

Oil Pressure

Clutch Engage

Input Speed Detected

Power

Output Speed

Detected

Pressure Transducer Detected

SAE J1939CAN

Loading...

Loading...