43

2009 DURATECH TUB GRINDER OPERATING INSTRUCTIONS

3.28 Adjusting the conveyor belt tracking

A. When a new belt is installed, use only genuine DuraTech Industries parts.

1. Begin by adjusting the drive roller so that the mounting bearings are the same distance from the end of the

conveyor frame. This ensures that the roller centerline is square with conveyor frame. Adjust the idler

roller bolts so that they are equal on both sides of the conveyor.

B. If the belt is running to the right side, perform the following steps:

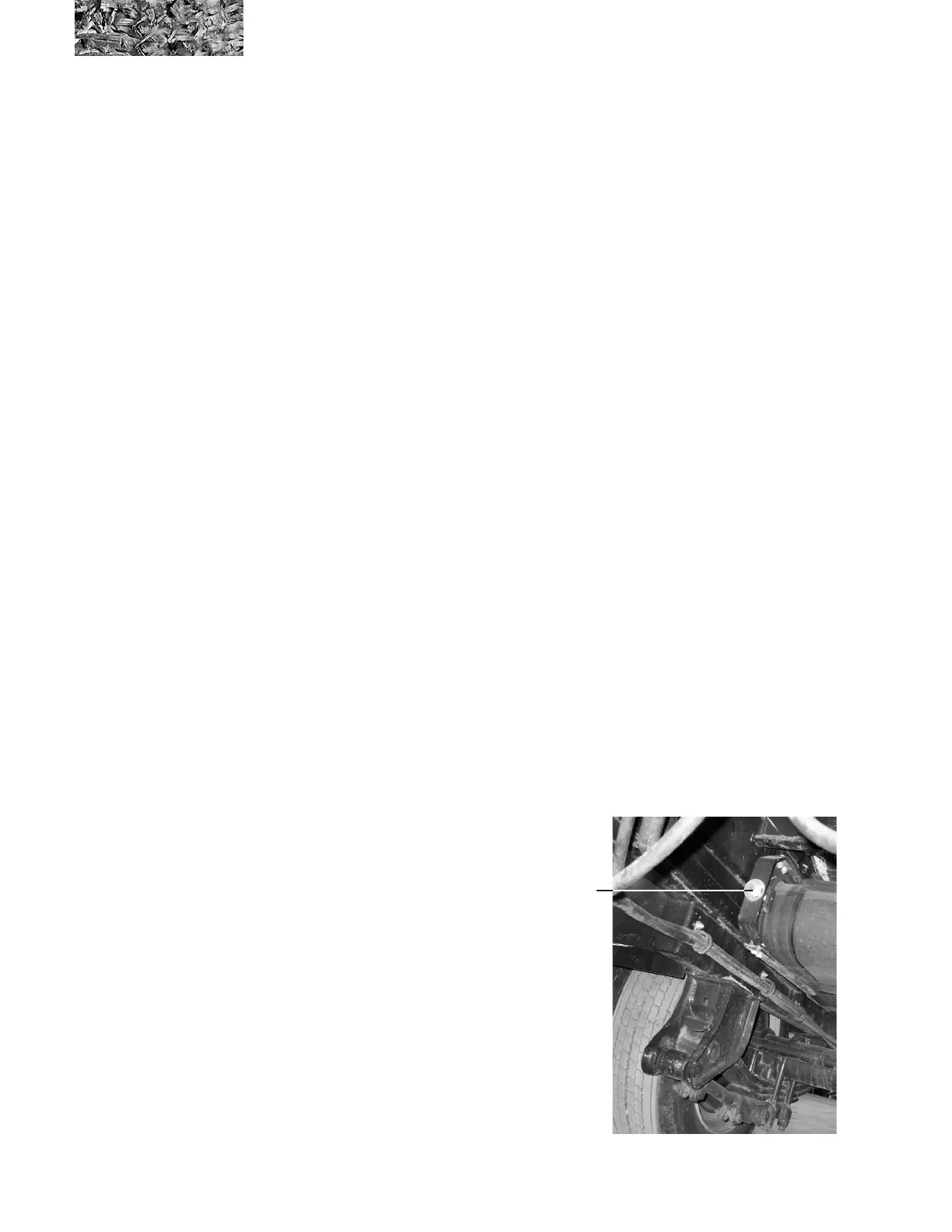

1. Adjust the idler roller adjustment bolt on the right side of the conveyor (gure 3.4 & 3.5). Increase

tension by approximately 1/2 turn of the adjusting nut.

2. Make certain that all personnel are clear of machine and the start engine. Engage the hydraulic conveyor

drive switch.

3. Observe conveyor belt tracking from a safe location.

4. If further adjustment is required, disengage hydraulic conveyor drive switch and shut down the machine

using the normal shutdown procedure.

5. Some adjustment of the drive roller may be required if no improvement is noted by adjusting the idler

roller tension.

6. Repeat steps 1‑5 until proper tracking is achieved.

C. If the belt is running to the left side, perform the following steps:

1. Adjust the idler roller tension bolt on the right side of the conveyor. Decrease the tension by

approximately 1/2 turn of the adjusting nut.

2. Make certain that all personnel are clear of machine and start engine. Engage the hydraulic conveyor

drive switch.

3. Observe the tracking of the conveyor belt from a safe location.

4. If further adjustment is required, disengage hydraulic conveyor drive switch and shutdown using the

normal shutdown procedure.

5. Some adjustment of the drive roller may be required if no improvement is noted by adjusting the idler

roller tension.

6. Repeat steps 1‑5 until proper tracking is achieved.

gure 3.5

tracking adjustment

bolt

(belly conveyor)

( REV. 08-04 )

Loading...

Loading...