70

2009 DURATECH TUB GRINDER OPERATING INSTRUCTIONS

MOUNTING

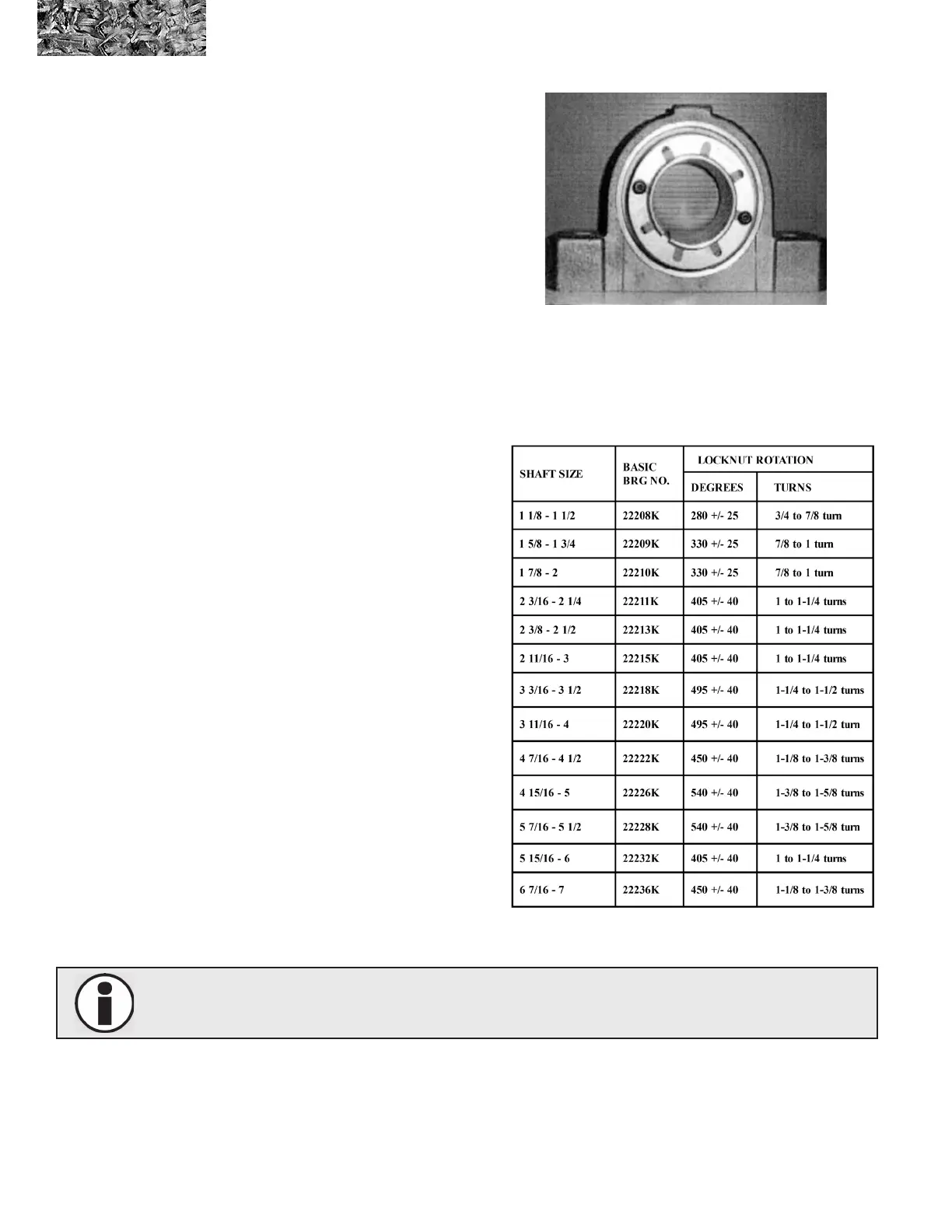

Install the non expansion unit rst.

1. Apply a coating of light oil or other rust inhibitor to

the adapter area of the shaft.

2. Before mounting bearing to shaft, remove

lockplate from bearing and turn locknut

counterclockwise one to two turns to allow adapter

to expand fully. The unit is now shaft ready. Slide

the bearing to the desire position on the shaft.

3. Proper locking of this unit to the shaft is based

on turning the locknut clockwise a predetermined

number of degrees shown for each bore size on

Table 1. The turning of the locknut must start from

a “ZERO reference point.” This “ZERO reference

point’ is dened as the point when the clearance

between adapter sleeve, shaft and bearing bore

has been removed, and all surfaces are in metal to

metal contact

3A. To reach the ‘ZERO Reference Point,” rotate

locknut clockwise, using both hands, as tight as

possible When mounting bearings with shaft sizes

3 15/16” and larger the following TEST must be

performed. As a test to insure you have reached

the “ZERO Reference Point” tap on the face of the

nut with a hammer and attempt to rotate the nut

using both hands

If the nut will not rotate then you

have reached the ‘ZERO Reference Point’ and you

should proceed to step 4. if you can rotate the nut,

using both hands, then you have not reached the

true ‘ZERO Reference Point,” and should repeat

step 3A until ‘ZERO Reference Point” is obtained.

NOTE: All Weight Must Be Removed From The Bearing When Obtaining The “ZERO Reference

Point.”

Picture 1

Loading...

Loading...