6 Device installation

6.1 Hydraulic installation

6.1.1 Installation examples

The installation examples and applications provided here are of a functional nature.

They give an overview of installation types which are correct or to be avoided for the correct

functioning of the pump.

Specific measures and protection devices for the metering of dangerous or aggressive

chemicals are not provided here.

When using such chemicals, always observe the legal regulations and the relevant product

datasheet.

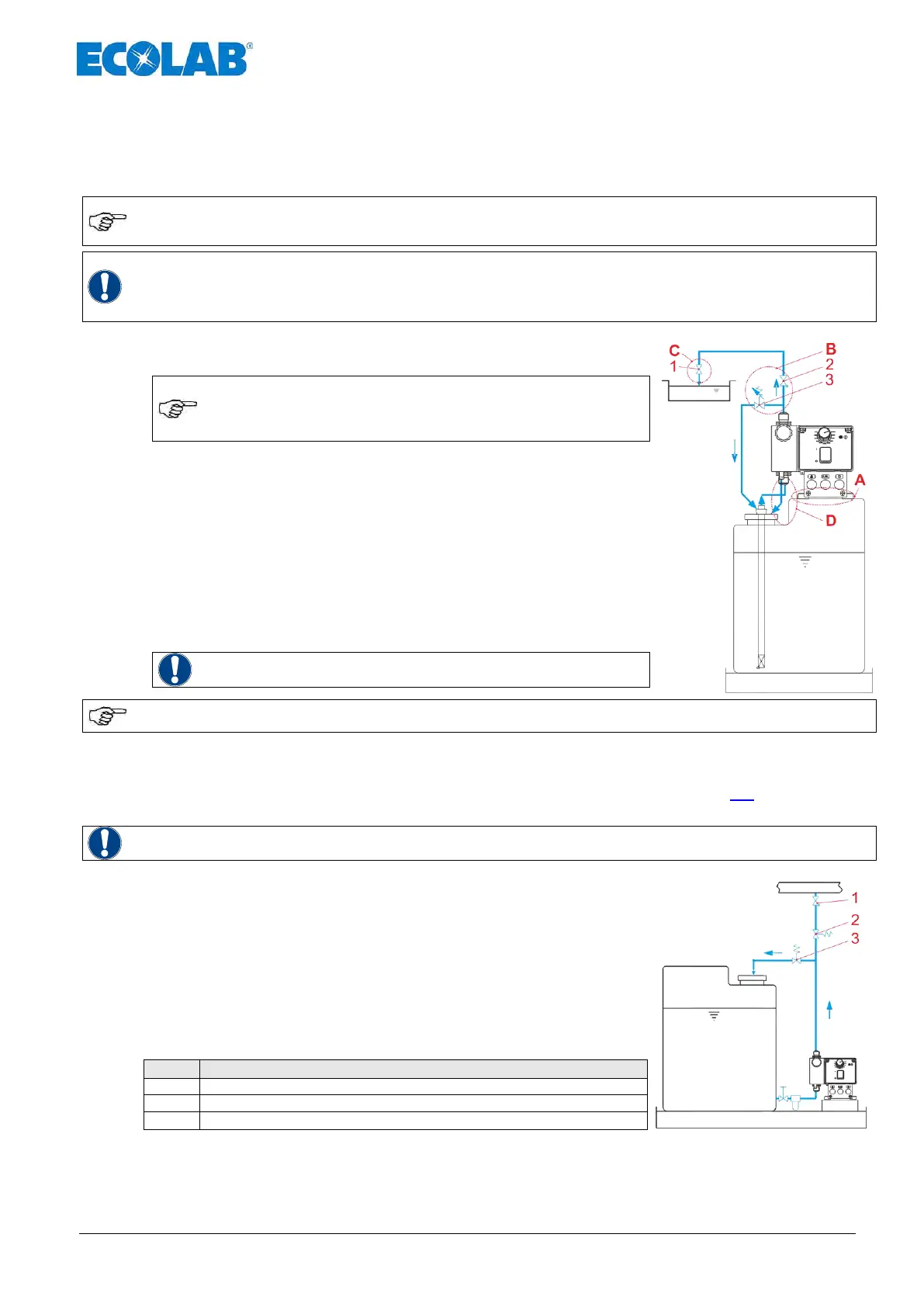

A) The arrangement of the metering pump should preferably be

made on and/or over the metering container.

For media with a tendency towards sedimentation,

the bottom admission valve or foot valve of the

suction line / suction lance must be fitted above

the anticipated layer of sludge.

B) Between the back-pressure in the injection point and the

pressure at the metering pump a positive difference of

pressure must prevail of at least 0.1 MPa (1 bar). If this is not

the case, a pressure control valve (pos. 2) must be built into

the metering line.

In addition it recommends to install itself for the avoidance of

inadmissibly high pressures in the metering line an

appropriate safety overflow valve (pos. 3). The by-pass pipe

of this valve should be led back pressure-free into the

container.

The overflow line never be fed back into the

suction line of the metering pump.

In place of a pressure valve and an overflow valve also a multifunction valve (MFV) from our

delivery program can be used.

C) A spring-loaded injection or metering valve (pos. 1) should be installed at the injection point

(including with supplying metered amounts into depressurised systems).

D) For easy venting of the metering pump, the vent connection (see chapter 5.1, “Setup”,

Pos. 6) should be fed back into the metering medium container via a separate pipe.

The venting pipe must never be fed back into the suction side of the metering pump!

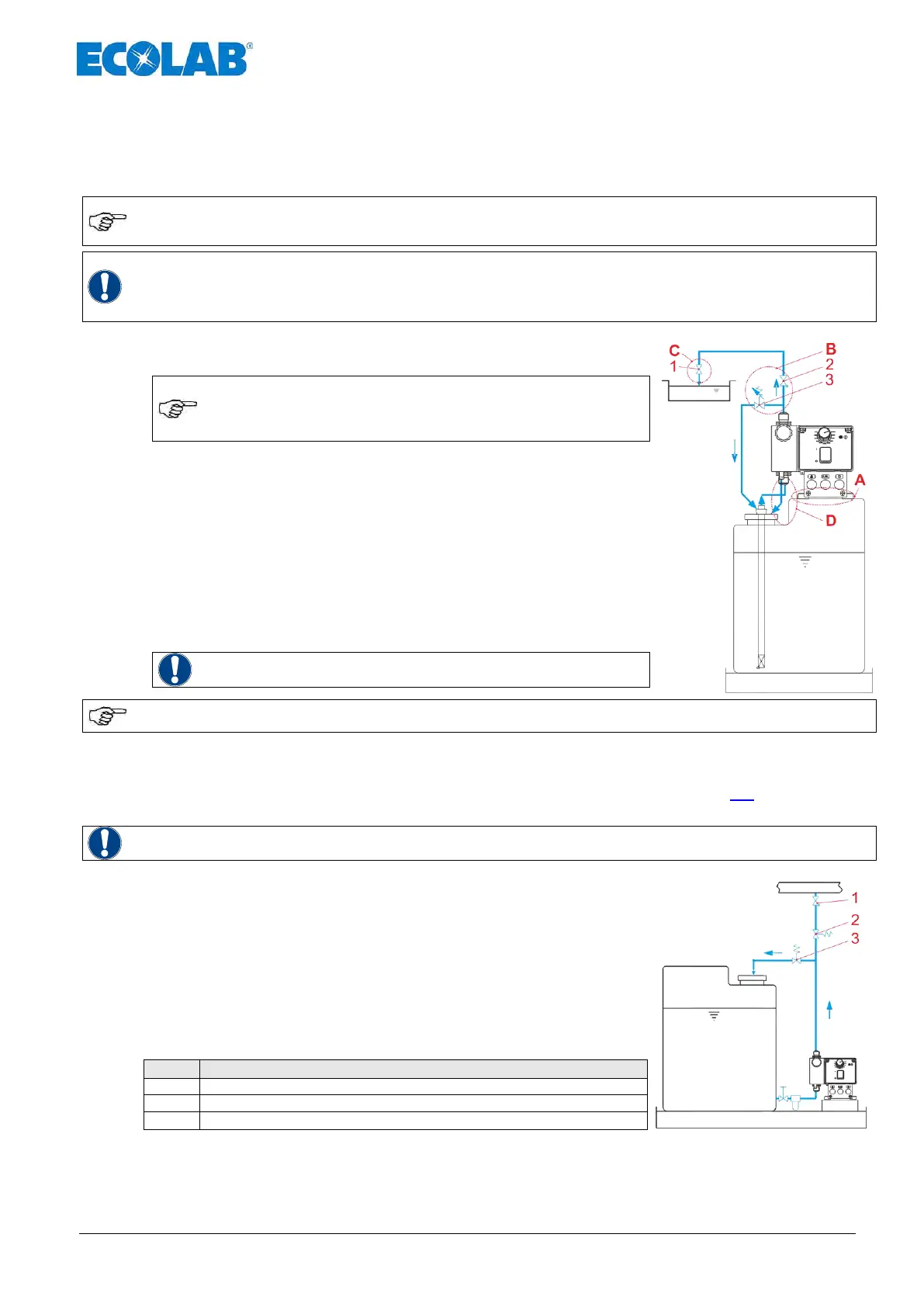

For outgassing media and products with a viscosity of

> 100 mPas, flooded suction is recommended.

In using this method, however, ensure that the injection point is

positioned over the discharge container and/or an appropriate

pressure control valve (pos. 2) is installed.

These measures prevent the discharge container from being

siphoned empty.

Injector valve / Metering valve

Loading...

Loading...