A352-03-880 Issue B

Page 4 © Edwards Limited 2015. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Introduction

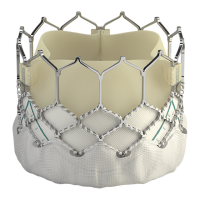

Figure 4 - Oil filter

1.2 Description

The ES range of pumps are rotary vane, oil-sealed vacuum pumps designed for reliable, long-term operation in both

laboratory and industrial environments.

The pump operating range extends from atmospheric pressure to the maximum continuous vacuum rating of the

pump.

1.3 Gas ballast

To pump high-vapour loads, gas ballast is delivered into the pump to prevent condensation of the vapour carried by

the pumped gases. This system reduces oil contamination and pump corrosion caused by condensed vapour from the

pumped gases.

Air or an inert gas can be introduced into the low-vacuum stage of the pump through the gas ballast inlet. A filter is

fitted in the gas ballast system to prevent the entry of dust into the pump.

For manual control, use the gas ballast control (Figures 1, 2, and 3, item 6). If this inlet is open to the atmosphere,

then:

With the gas ballast control open, when the pump is switched off, the pressure inside the pump will rise to

atmospheric pressure.

With the gas ballast control closed, when the pump is switched off, vacuum will slowly rise inside the pump.

These vacuum pumps are to be used for pumping non-aggressive gases containing no more than

25% oxygen. The gases must not be toxic or explosive. If the pump is to be used in an oxygen-rich

environment, it must be degreased in accordance with a specific procedure and must operate with

hydrocarbon-free oil.

Loading...

Loading...