1-10

1-101-10

1-10

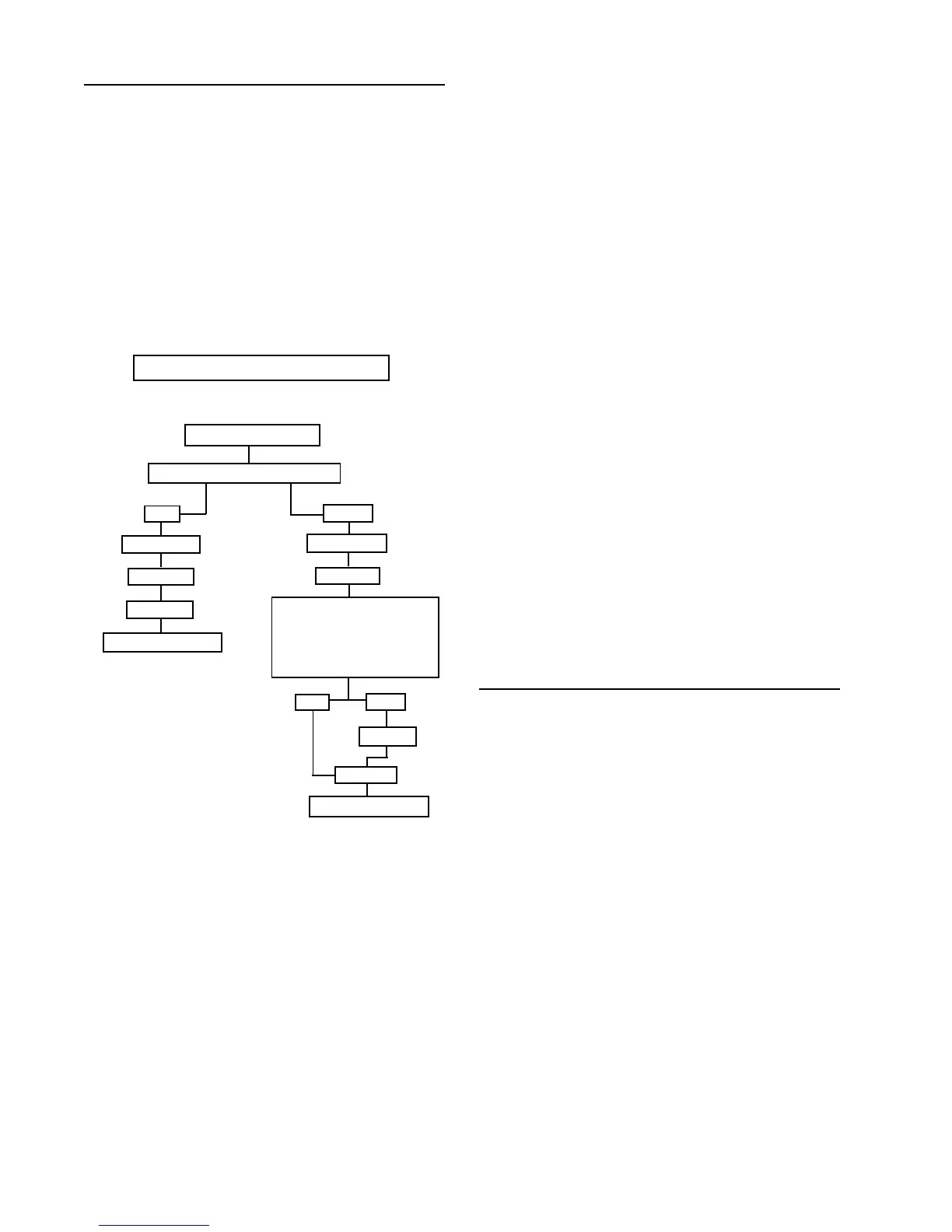

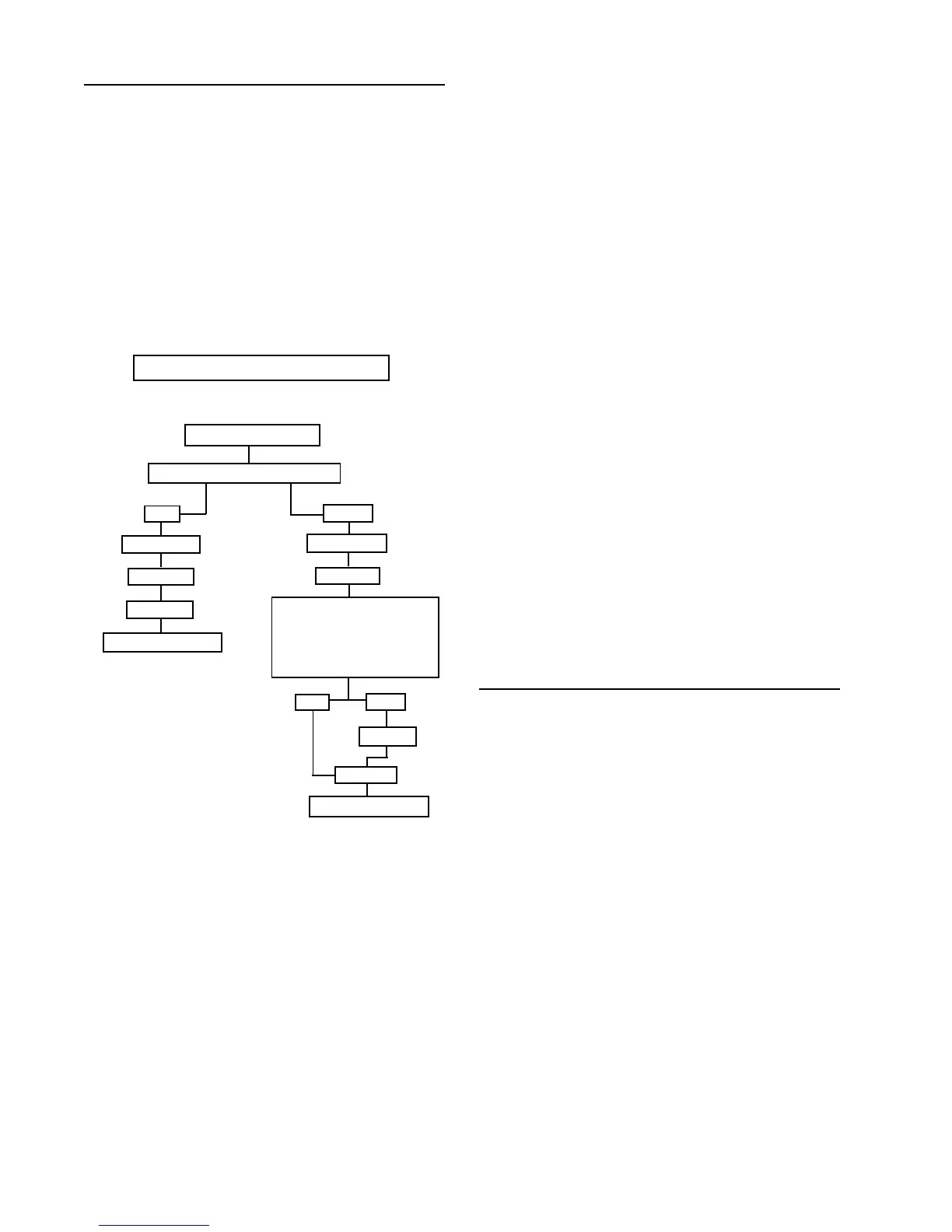

Sealed system diagnosis of R134A refriger-

ant systems is to be performed identically

to that of R12 systems. In fact, as shown in

the following flow chart, the service proce-

dures are virtually the same, except for low

side leaks, plugged capillary tube or com-

pressor failure which results in a system

flush.

IDENTIFY REFRIGERANTIDENTIFY REFRIGERANT

IDENTIFY REFRIGERANTIDENTIFY REFRIGERANT

IDENTIFY REFRIGERANT

R12R12

R12R12

R12

R134aR134a

R134aR134a

R134a

RECOVERRECOVER

RECOVERRECOVER

RECOVER

RECOVERRECOVER

RECOVERRECOVER

RECOVER

REPREP

REPREP

REP

AIRAIR

AIRAIR

AIR

REPREP

REPREP

REP

AIRAIR

AIRAIR

AIR

SWEEPSWEEP

SWEEPSWEEP

SWEEP

LOW SIDE LEAK,LOW SIDE LEAK,

LOW SIDE LEAK,LOW SIDE LEAK,

LOW SIDE LEAK,

PLUGGED CAPILLARYPLUGGED CAPILLARY

PLUGGED CAPILLARYPLUGGED CAPILLARY

PLUGGED CAPILLARY

TUBE, COMPRESSORTUBE, COMPRESSOR

TUBE, COMPRESSORTUBE, COMPRESSOR

TUBE, COMPRESSOR

REPLACEMENT?REPLACEMENT?

REPLACEMENT?REPLACEMENT?

REPLACEMENT?

FINAL CHARGEFINAL CHARGE

FINAL CHARGEFINAL CHARGE

FINAL CHARGE

NONO

NONO

NO

YESYES

YESYES

YES

FLUSH*FLUSH*

FLUSH*FLUSH*

FLUSH*

FINAL CHARGEFINAL CHARGE

FINAL CHARGEFINAL CHARGE

FINAL CHARGE

REFRIGERAREFRIGERA

REFRIGERAREFRIGERA

REFRIGERA

TT

TT

T

OR DIAGNOSISOR DIAGNOSIS

OR DIAGNOSISOR DIAGNOSIS

OR DIAGNOSIS

SWEEPSWEEP

SWEEPSWEEP

SWEEP

SEALED SYSTEMSEALED SYSTEM

SEALED SYSTEMSEALED SYSTEM

SEALED SYSTEM

* FLUSH INCLUDES COMPRESSOR

REPLACEMENT

Remember, before entering the sealed sys-

tem, all other systems must be tested and

properly repaired. These include the elec-

trical system, defrost system, control op-

eration, and air flow systems: evaporator

and condenser motors.

Before "turning aBefore "turning a

Before "turning aBefore "turning a

Before "turning a

screwdriver", many checks can be madescrewdriver", many checks can be made

screwdriver", many checks can be madescrewdriver", many checks can be made

screwdriver", many checks can be made

simply by using your senses:simply by using your senses:

simply by using your senses:simply by using your senses:

simply by using your senses:

DIAGNOSISDIAGNOSIS

DIAGNOSISDIAGNOSIS

DIAGNOSIS

LISTEN:LISTEN:

LISTEN:LISTEN:

LISTEN:

What is the customer complaint?

Are the fans operating?

Is the compressor operating?

LOOK:LOOK:

LOOK:LOOK:

LOOK:

Are ice cubes present?

Is the light on/off when the switch is

operated?

Are the controls set properly?

Do door gaskets seal properly?

Is there an ice buildup on the

evaporator cover?

Are the return air ducts free of ice?

TOUCH:TOUCH:

TOUCH:TOUCH:

TOUCH:

Is the evaporator cover warm?

Is air felt exhausting from the kick

plate?

Is air circulating in the freezer and

fresh food compartments?

Is the quarter inch discharge line

from the compressor hot?

Is the condenser warm?

SEALED SYSTEM DIAGNOSISSEALED SYSTEM DIAGNOSIS

SEALED SYSTEM DIAGNOSISSEALED SYSTEM DIAGNOSIS

SEALED SYSTEM DIAGNOSIS

Once it has been determined that the other

refrigerator systems are working properly,

a probable sealed system problem can be

confirmed through the use of a wattmeter

and checks of low and high side pressures.

Access valves are not to be left on a sealedAccess valves are not to be left on a sealed

Access valves are not to be left on a sealedAccess valves are not to be left on a sealed

Access valves are not to be left on a sealed

system after service.system after service.

system after service.system after service.

system after service. To measure low side

pressure, a temporary access valve can be

installed on the compressor process tube.

To remove the valve after repair, a pinch off

tool may be used to seal the tube while the

valve is removed and the hole brazed shut.

To check high side pressure, a temporary

access valve should be installed on the dis-

charge line. When the high side valve is in-

Loading...

Loading...