1-14

1-141-14

1-14

YY

YY

Y

oder Loopoder Loop

oder Loopoder Loop

oder Loop

YY

YY

Y

ODER LODER L

ODER LODER L

ODER L

OOP DIAGNOSTIC TESTOOP DIAGNOSTIC TEST

OOP DIAGNOSTIC TESTOOP DIAGNOSTIC TEST

OOP DIAGNOSTIC TEST

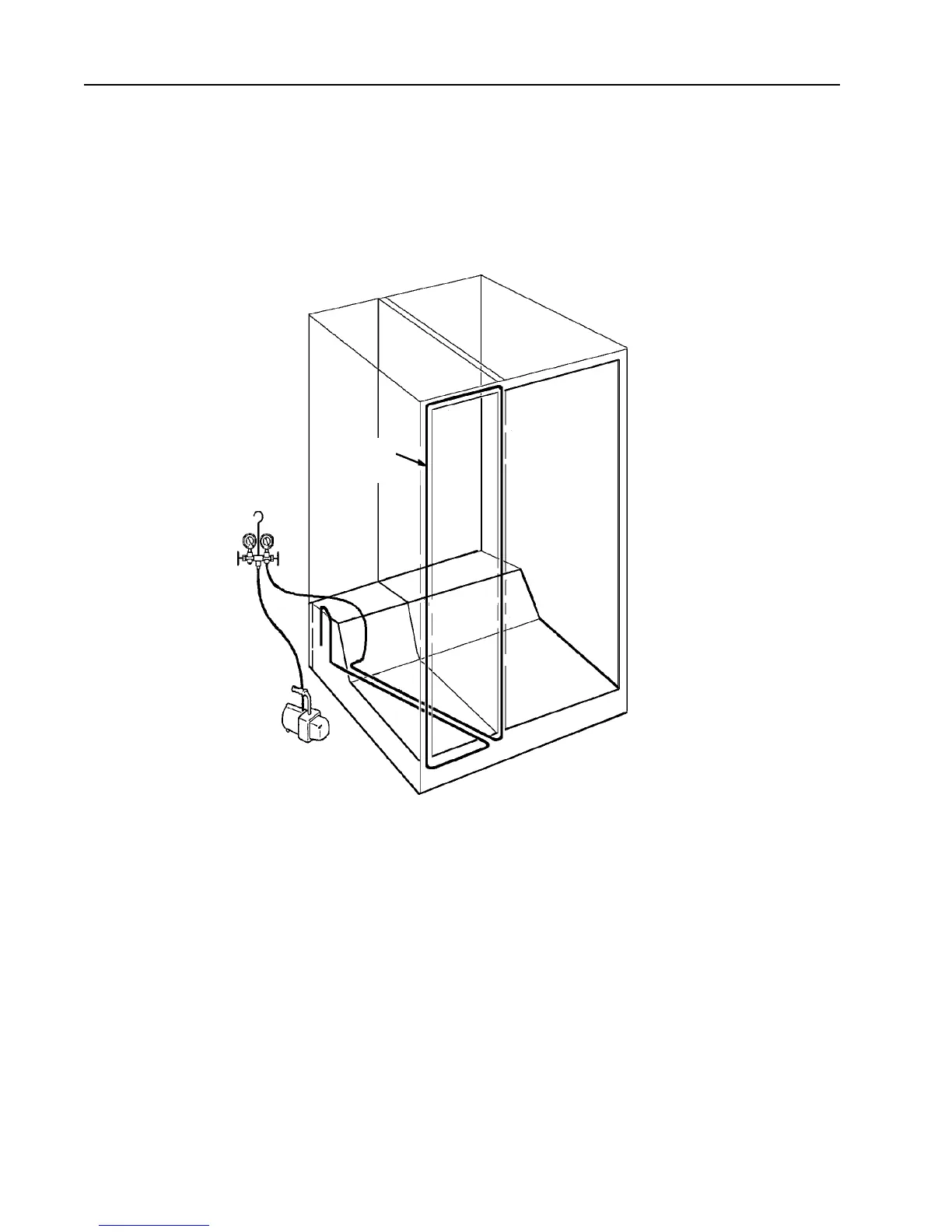

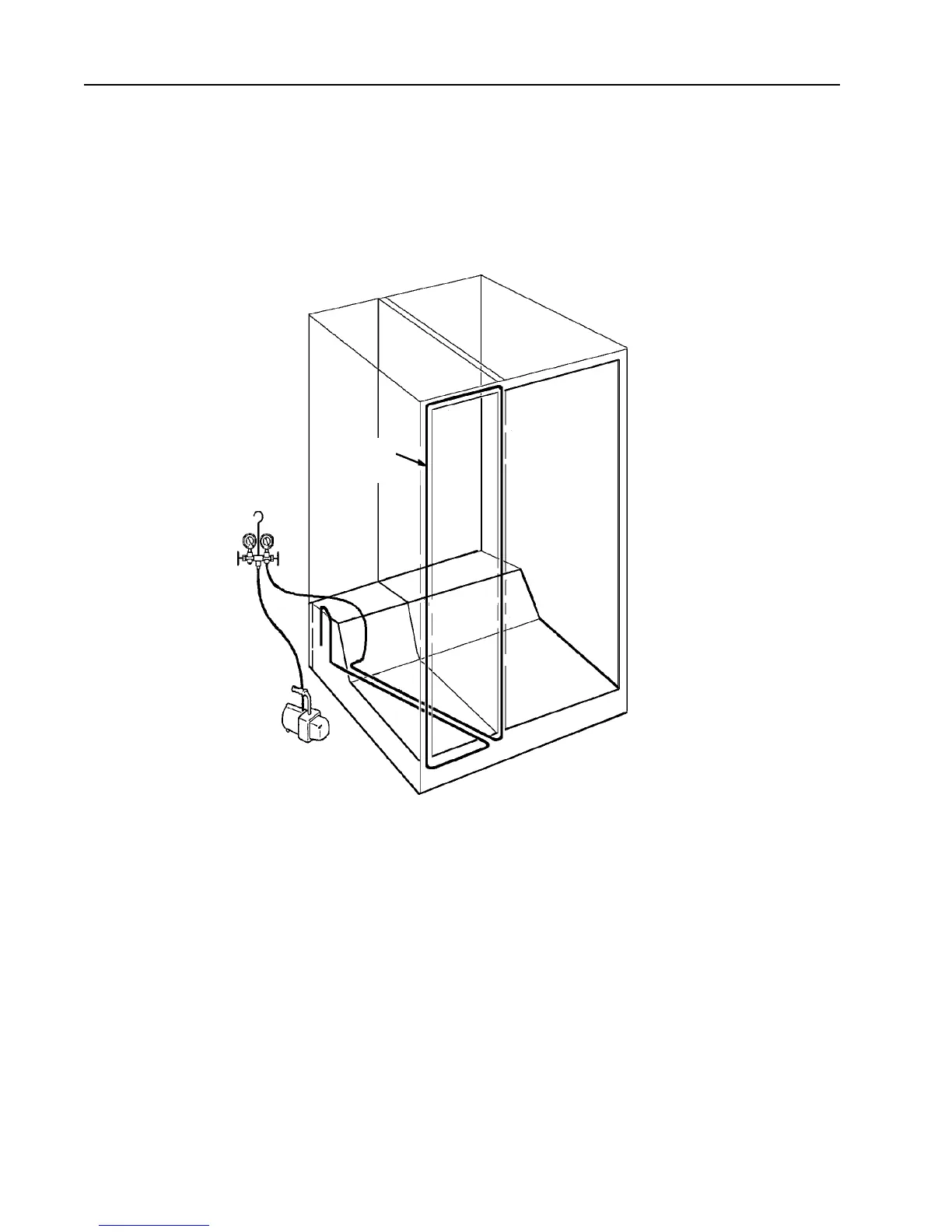

1. Isolate yoder loop from remainder of sealed system.

2. Cap or seal one end of the loop (braze or use process adaptor and cap).

3. Attach process adaptor to open end of loop.

4. Attach compound gauge and vacuum pump to the loop.

5. Pull a vacuum and close valve to test for leak in the loop.

6. If unit holds a vacuum, no leak is indicated. Reconnect the yoder loop to the system, replace

the drier and recharge the system to specifications.

A VA V

A VA V

A V

ACUUM WILL BE MAINTACUUM WILL BE MAINT

ACUUM WILL BE MAINTACUUM WILL BE MAINT

ACUUM WILL BE MAINT

AINED IF THE SYSTEM IS GOODAINED IF THE SYSTEM IS GOOD

AINED IF THE SYSTEM IS GOODAINED IF THE SYSTEM IS GOOD

AINED IF THE SYSTEM IS GOOD

..

..

.

The yoder loop is a non-replaceable component of the sealed system routed within the

walls of the cabinet. To diagnose the yoder loop, the tubing must be isolated from the

sealed system. This procedure is shown below. If the loop fails to hold the vacuum, a

heater repair assembly is to be installed and the loop bypassed by connecting the con-

denser outlet tube directly to the inlet of the drier.

YY

YY

Y

oderoder

oderoder

oder

CondenserCondenser

CondenserCondenser

Condenser

LoopLoop

LoopLoop

Loop

Loading...

Loading...