1-17

1-171-17

1-17

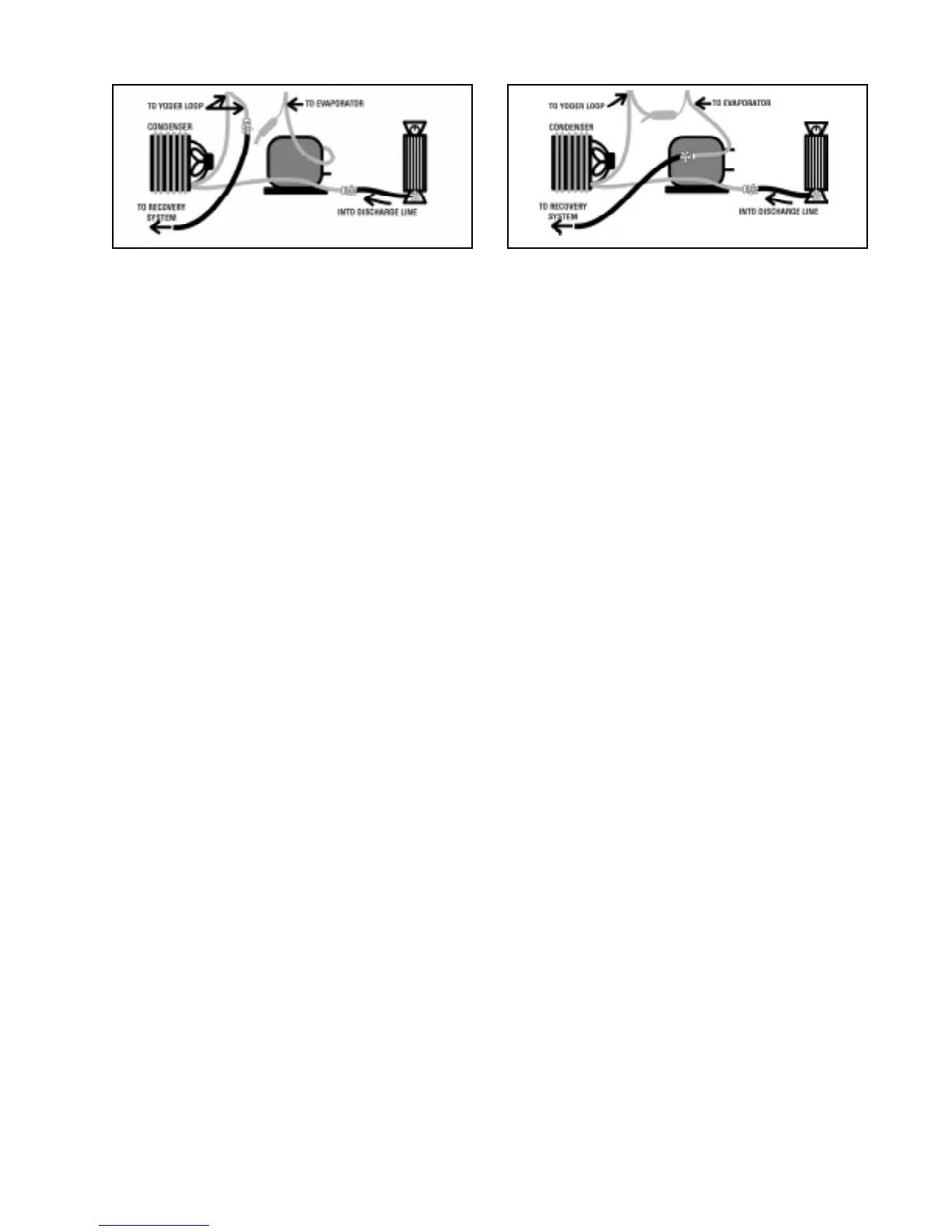

FIGURE 2FIGURE 2

FIGURE 2FIGURE 2

FIGURE 2

Flush the entire system (less compressor)

out the suction line.

Flush into discharge line, through hi-side

and out the yoder loop at drier inlet.

FIGURE 1FIGURE 1

FIGURE 1FIGURE 1

FIGURE 1

2. Replace the Drier2. Replace the Drier

2. Replace the Drier2. Replace the Drier

2. Replace the Drier

Score and break either one of the two inlet

lines on the new drier (the other line will

remain sealed until the sweep charge, at

which time it will be the process tube). Pre-

pare the drier outlet side for connection to

the capillary tube. The capillary tube should

be inserted about 3/4 inch into the drier to

prevent solder alloy from plugging the cap-

illary tube or the capillary tube extending

too far into the drier and contacting the

screen. To facilitate the installation, place a

slight bend in the capillary tube about 3/4

inch from the end and insert into the drier.

Remove the process tube adapter from the

yoder outlet and prepare the tube for con-

nection to the drier inlet. The drier inlet joint

will be the only copper-to-steel connection

which will require the silver solder and flux.

To help prevent flux from entering the sys-

tem, first insert the line from the yoder loop

into the drier inlet, then apply the flux. Braze

both the inlet and the outlet joints of the re-

placement drier.

3. Isolate and flush the remainder of3. Isolate and flush the remainder of

3. Isolate and flush the remainder of3. Isolate and flush the remainder of

3. Isolate and flush the remainder of

the systemthe system

the systemthe system

the system

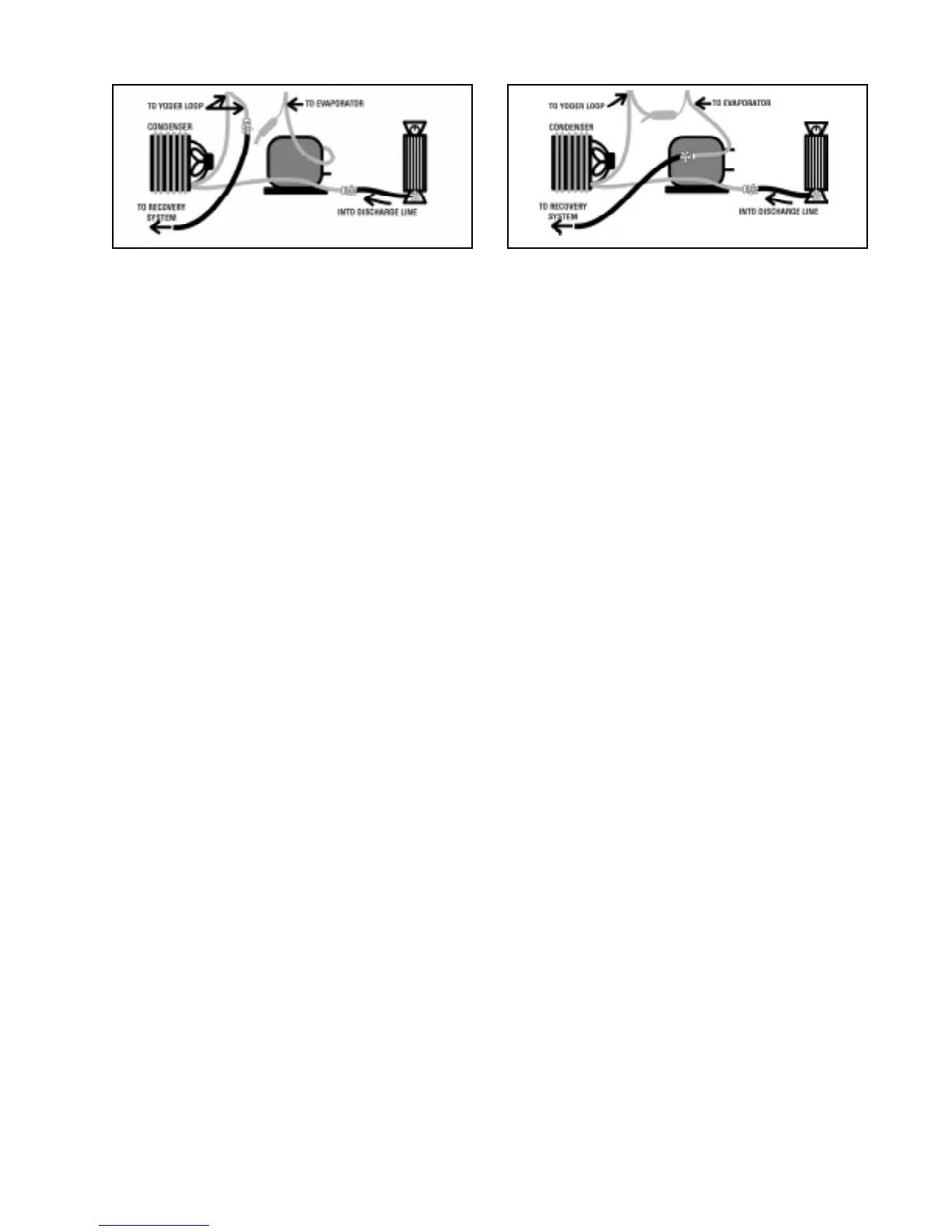

Score and break the suction line close

enough to the old compressor to be able

to reconnect it to the replacement com-

pressor later. Attach a process tube adapter

to the evaporator side of the suction line.

Connect the hand valve and hose from the

recovery equipment to this adapter

(figure(figure

(figure(figure

(figure

2)2)

2)2)

2). Be certain that the pressure in the charg-

ing cylinder is about 30 p.s.i.g. above ambi-

ent temperature. Start the recovery unit and

open the hand valve to the suction line.

Release four (4) ounces of R134a from the

charging cylinder into the system. It will take

about 15 minutes for the refrigerant to pass

through the condenser, yoder loop, drier,

capillary tube, evaporator, suction line and

into the recovery system. This 15 minutes

time can be utilized to remove the old com-

pressor

(figure 3)(figure 3)

(figure 3)(figure 3)

(figure 3) and prepare the new com-

pressor by mounting into place and wiring

electrically. Remember to leave the plugs

in place until brazing

(refer to (refer to

(refer to (refer to

(refer to

figure 4).figure 4).

figure 4).figure 4).

figure 4).

Loading...

Loading...