1-20

1-201-20

1-20

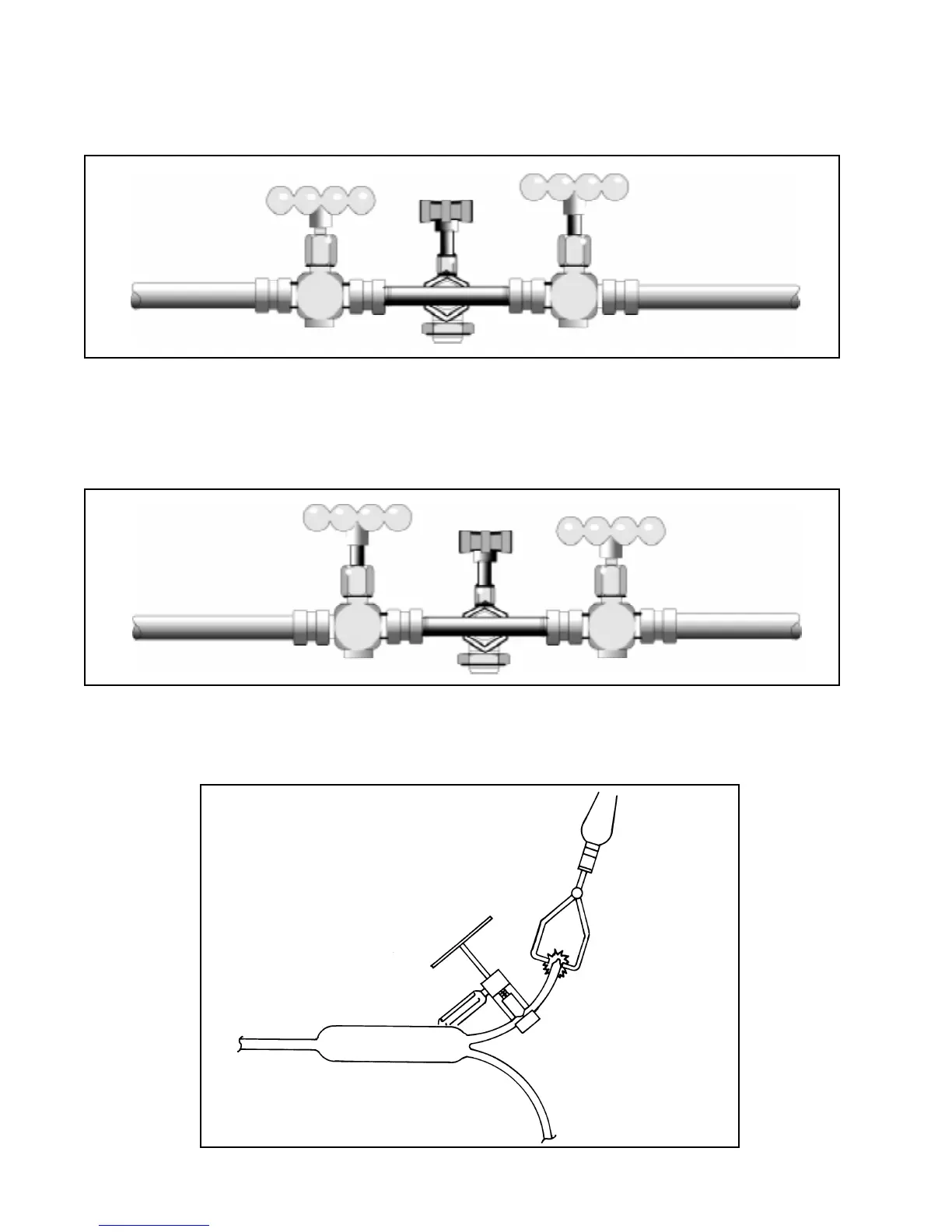

TOTO

TOTO

TO

CHARGINGCHARGING

CHARGINGCHARGING

CHARGING

CYLINDERCYLINDER

CYLINDERCYLINDER

CYLINDER

TOTO

TOTO

TO

RECOVERYRECOVERY

RECOVERYRECOVERY

RECOVERY

SYSTEMSYSTEM

SYSTEMSYSTEM

SYSTEM

AA

AA

A

BB

BB

B

CC

CC

C

ACCESS VACCESS V

ACCESS VACCESS V

ACCESS V

ALAL

ALAL

AL

VEVE

VEVE

VE

TOTO

TOTO

TO

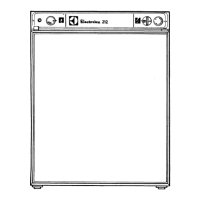

CHARGINGCHARGING

CHARGINGCHARGING

CHARGING

CYLINDERCYLINDER

CYLINDERCYLINDER

CYLINDER

AA

AA

A

CC

CC

C

BB

BB

B

ACCESS VACCESS V

ACCESS VACCESS V

ACCESS V

ALAL

ALAL

AL

VEVE

VEVE

VE

TOTO

TOTO

TO

RECOVERYRECOVERY

RECOVERYRECOVERY

RECOVERY

SYSTEMSYSTEM

SYSTEMSYSTEM

SYSTEM

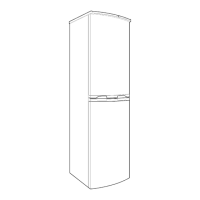

Step 3.Step 3.

Step 3.Step 3.

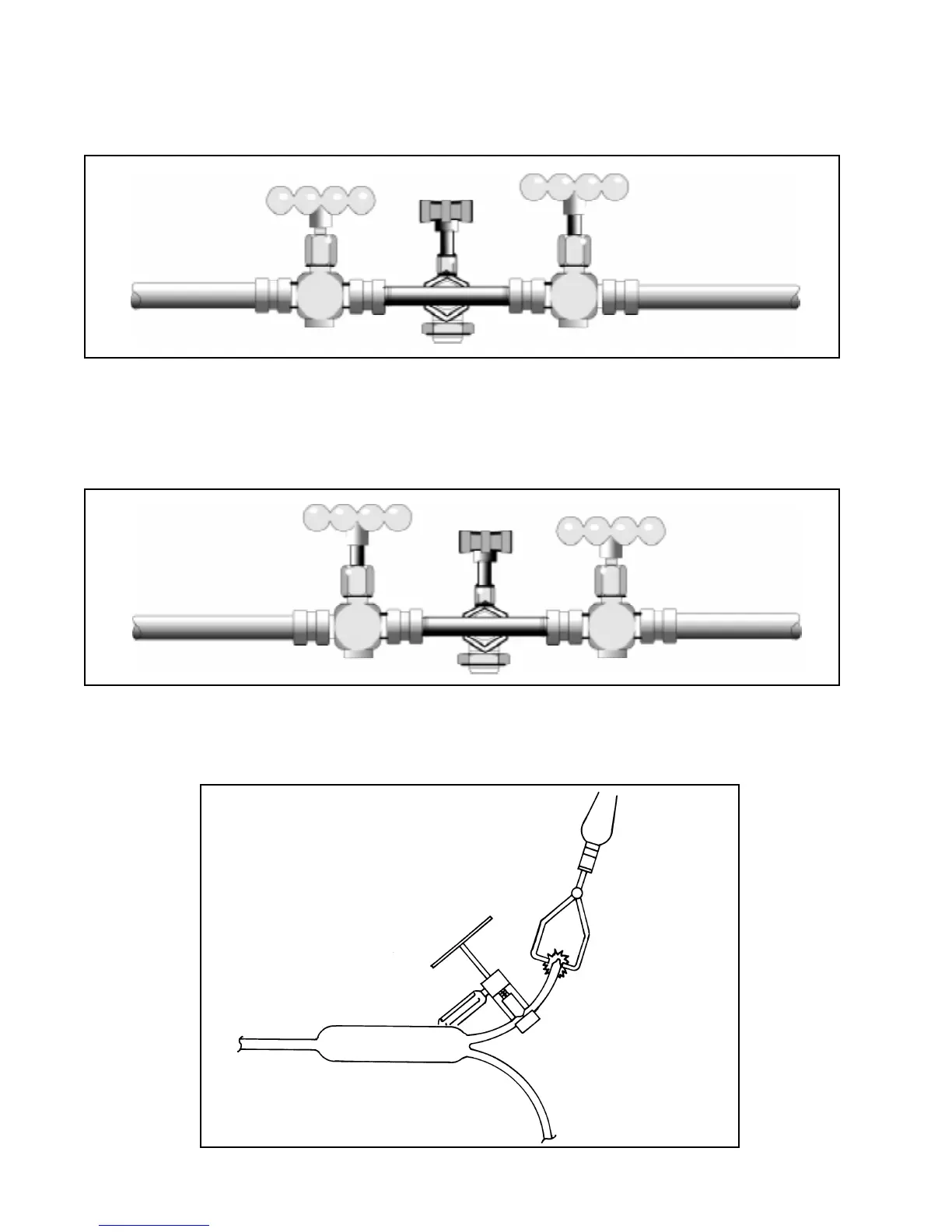

Step 3. Leave valve A closed and valve C open. System compressor still running,

open valve B to allow refrigerant to flow into the recovery system. After vacuum

has been held, turn off system compressor.

Step 4.Step 4.

Step 4.Step 4.

Step 4. Close valve B. Liquid refrigerant still present to valve A and charging cylinder

pressure is 30 p.s.i.g. above room ambient. Open valve A to slowly allow the proper

refrigerant charge into the system. Close valve A. If needed, valve C can be closed

and valves A and B opened to recover refrigerant in the hoses and charging cylinder.

Step 5.Step 5.

Step 5.Step 5.

Step 5. Use pinch-off tool to seal the process tube between the drier and the access

valve. Remove the access valve and braze the opening. After the required five minute

equalization time, start the system compressor.

Loading...

Loading...