62

Mechanical Adjustment

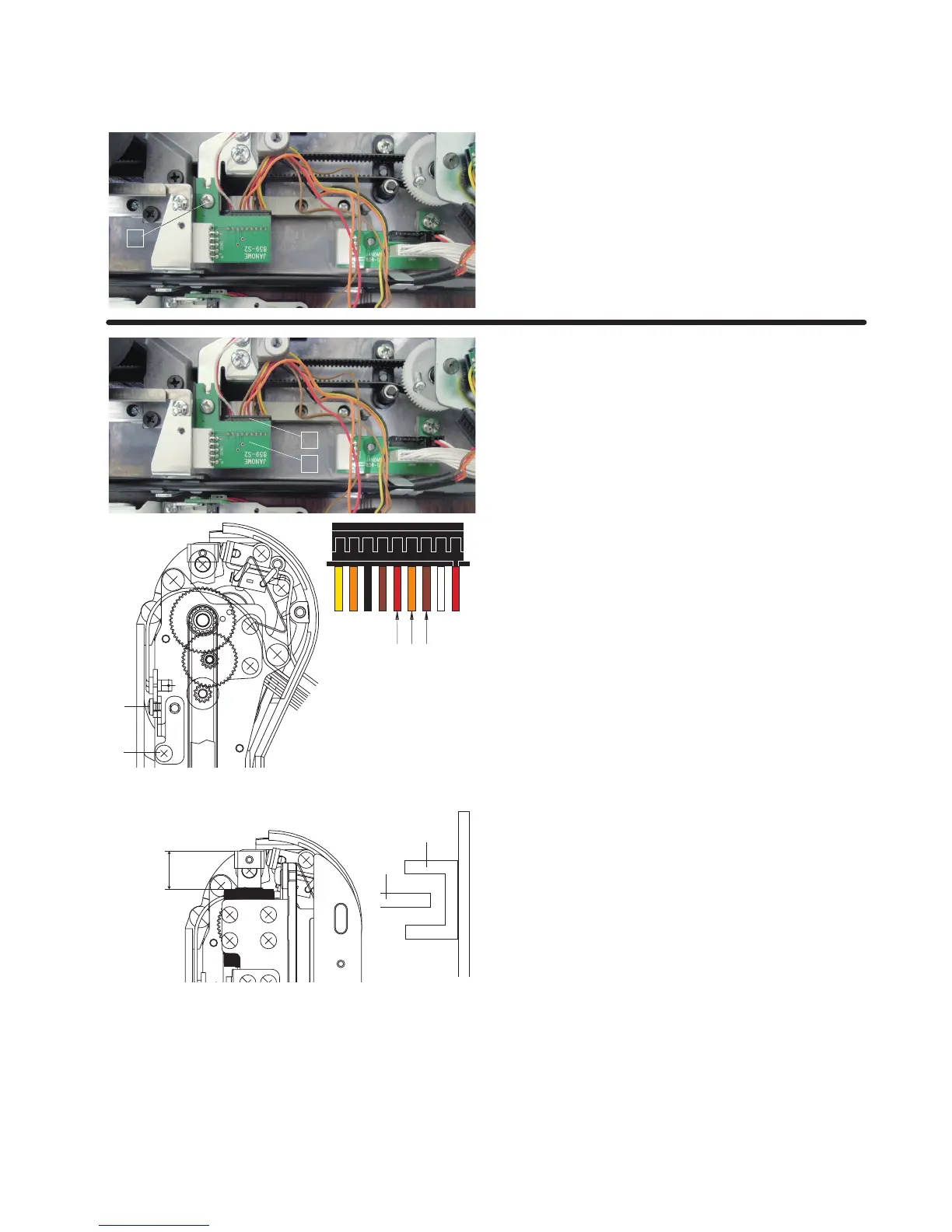

Replacing Printed Circuit Board S2

z Remove the Y-carriage cover (lower) (refer to pages 51-

52).

Remove the setscrew

q.

Disconnect the connector and flexible cable from the

printed circuit board S2.

Remove the printed circuit board S2.

q

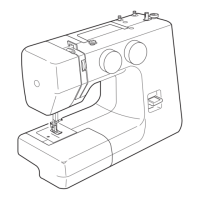

ReplacingY-sensor

•RemovingY-sensor

z

Remove the Y-carriage cover (lower) (refer to pages 51-

52).

Disconnect the connector

q from the printed circuit board

S2

w.

x Pry up the lock tab of the connector with a precision driver

and pull out the red

e, orange r and brown t.

c Remove the setscrew y.

Remove the Y-sensor.

q

w

ert

y

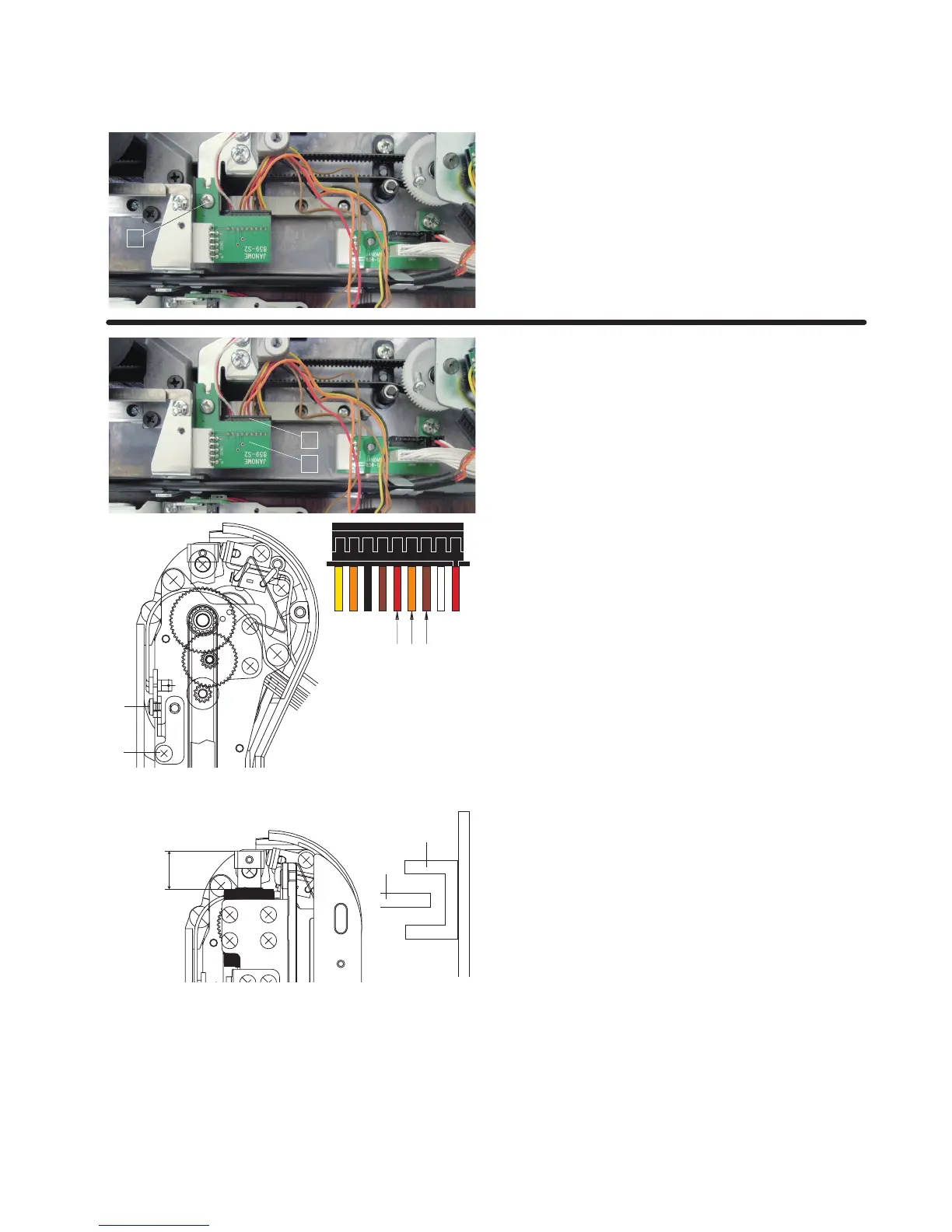

•AttachingY-sensor

z

Adjust the Y-sensor height so the shielding plate u should

be positioned at the middle of the sensor

i as illustrated.

Tighten the setscrew

y to attach the Y-sensor.

Insert the cords

e, r and t to the connector.

Plug the connector to the printed circuit board S2.

x Attach the embroidery unit to the MC12000.

Insert the machine plug into the power inlet.

Insert the power supply plug into the wall outlet and turn

the power switch on.

c The embroidery unit carriage position is initialized.

The range A (between the edge of Y-carriage LM guide

and the edge of carriage) should be 13.5 mm.

If not, turn the setscrew

o and adjust the Y-sensor

position.

If the range A is larger than 13.5 mm, move the Y-sensor

set plate in the direction of “B”.

If the range A is smaller than 13,5 mm, move the Y-sensor

set plate in the direction of “C”

Initialize the embroidery unit again and be sure the range

between A and B is in the range of 10.1 mm to 11.1 mm. If

not, repeat the procedure and adjust the range again.

13.5 mm

i

u

o

A

C

B

Loading...

Loading...