126 Functional description CG Drives & Automation 01-7491-01r0

Acceleration Time to Minimum

Speed [335]

If minimum speed, [341]>0 rpm, is used in an application,

the AC drive uses separate ramp times below this level. With

“Acc<MinSpeed [335]” and “Dec<MinSpeed [336]” you can

set the required ramp times. Short times can be used to

prevent damage and excessive pump wear due too little

lubrication at lower speeds. Longer times can be used to fill

up a system smoothly and prevent water hammer due to

rapidly exhausting air from the pipe system.

If a Minimum speed is programmed, this parameter will be

used to set the acceleration time parameter [335] for speeds

up to minimum speed at a run command. The ramp time is

defined as the time it takes for the motor to accelerate from

0 rpm to nominal motor speed.

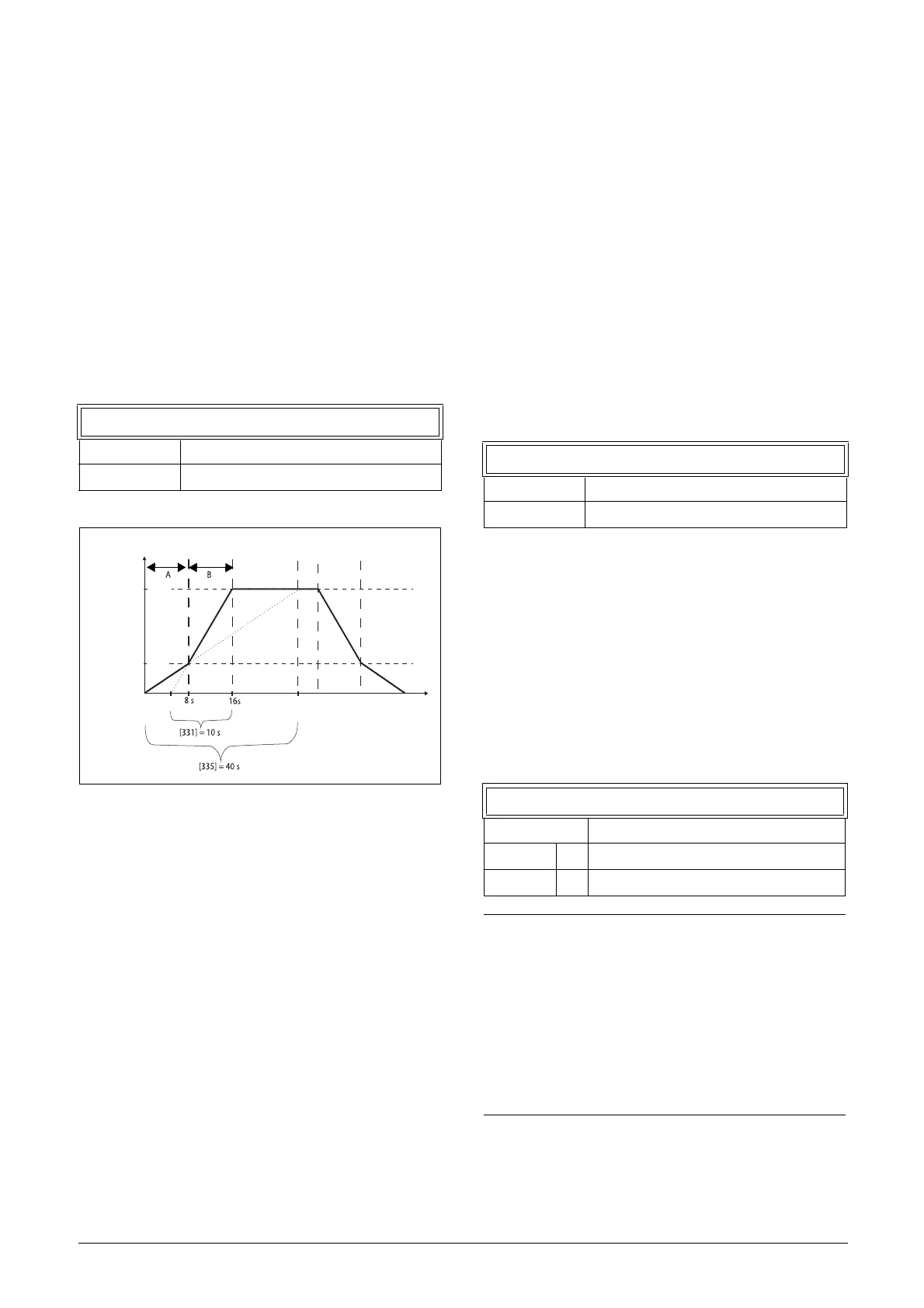

Fig. 104 Calculation example of accelerating times

(graphics not proportional).

Example

“Motor speed [225]” 3000 rpm

Minimum speed [341] 600 rpm

Maximum speed [343] 3000 rpm

Acceleration time [331] 10 seconds

Deceleration time [332] 10 seconds

Acc>Min speed[335] 40 seconds

Dec<Min speed[336] 40 seconds

A. The drive will start from 0 rpm and accelerate to

Minimum speed [341] = 600 rpm in 8 seconds

according to ramp time parameter

Acc>Min speed [335].

Calculated as following:

600 rpm is 20% of 3000 rpm => 20% of 40 s = 8 s.

B. The acceleration continues from minimum speed level

600 rpm to maximum speed level 3000 rpm with

acceleration rate according to ramp time Acceleration

time [331].

Calculate by following:

3000 - 600= 2400 rpm which is 80 % of 3000 rpm =>

acceleration tim is 80 % x 10 s = 8 s.

This means that the total acceleration time from 0 -

3000 rpm will take 8 + 8 = 16 seconds.

Deceleration Time from Minimum

Speed [336]

If a minimum speed is programmed, this parameter will be

used to set the deceleration time from the minimum speed

to 0 rpm at a stop command. The ramp time is defined as

the time it takes for the motor to decelerate from the

nominal motor speed to 0 rpm.

Acceleration Ramp Type [337]

Sets the type of all the acceleration ramps in a parameter set.

See fig. 105. Depending on the acceleration and

deceleration requirements for the application, the shape of

both the ramps can be selected. For applications where speed

changes need to be started and stopped smoothly, such as a

conveyor belt with materials that can drop following a quick

speed change, the ramp shape can be adapted to a S-shape

and prevent speed change shocks. For applications that are

not critical in this, the speed change can be fully linear over

the complete range.

335 Acc<Min Spd

Default: 10.0 s

Range: 0.50-3600 s

time

rpm

Motor Speed

Max speed

Min speed

[341]

[343]

[225]

3000

600

336 Dec<Min Spd

Default: 10.0 s

Range: 0.50-3600 s

337 Acc Rmp

Default: Linear

Linear 0 Linear acceleration ramp.

S-Curve 1 S-shape acceleration ramp.

NOTE: For S-curve ramps the ramp times, [331] and

[332], defines the maximum acceleration and

deceleration rated, i.e. linear part of S-curve, just as

for the linear ramps. The S-curves are implemented

so that for a speed step below sync speed the ramps

are fully S-shaped while for larger steps the middle

part will be linear. Therefore will a S-curve ramp from

0 –sync speed take 2 x Time while a step from 0–2 x

sync speed will take 3 x Time (middle part 0.5sync

speed – 1.5sync speed linear). Also valid for menu

[338], Deceleration ramp type.

Loading...

Loading...