CG Drives & Automation 01-7491-01r0 Installation 31

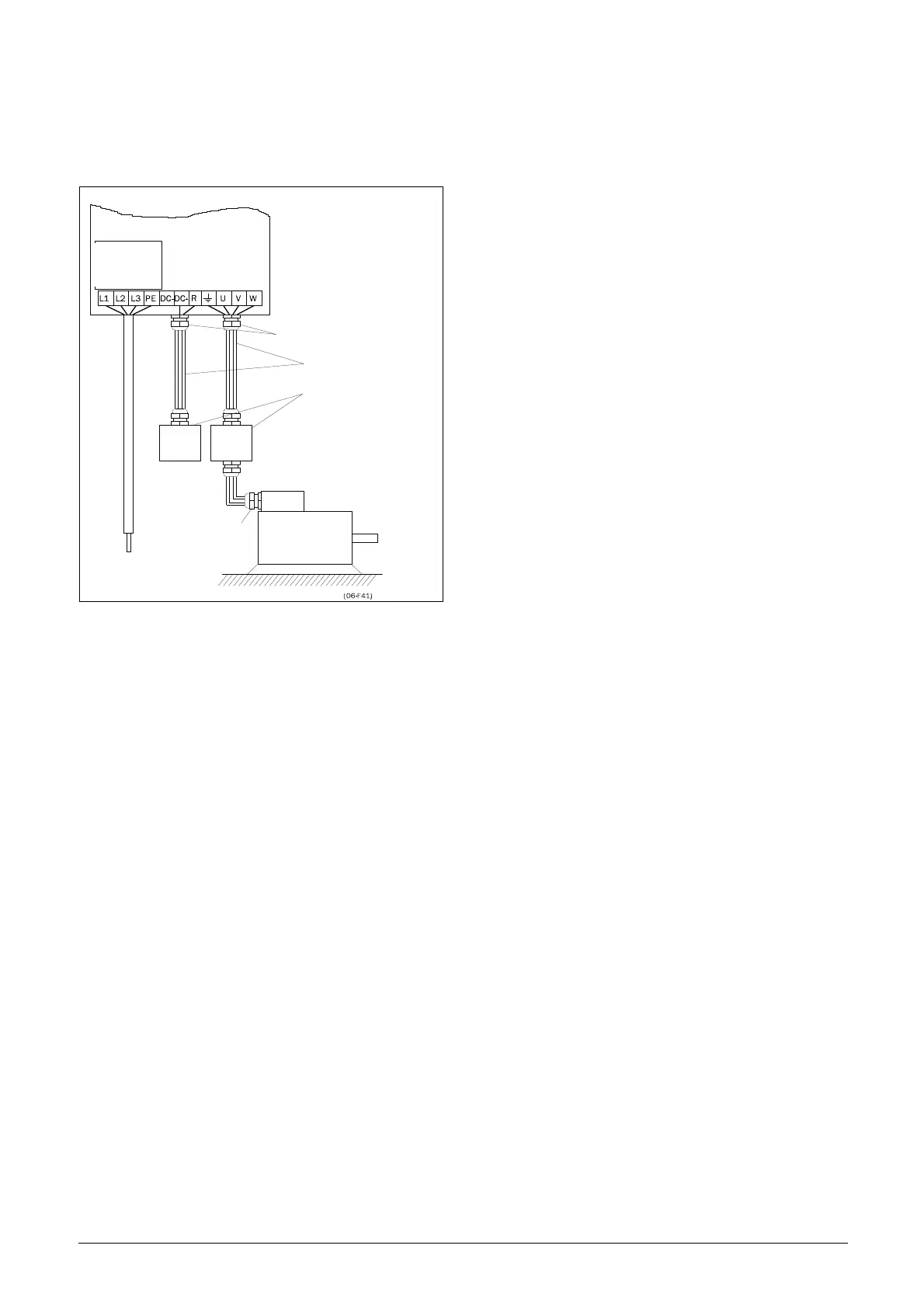

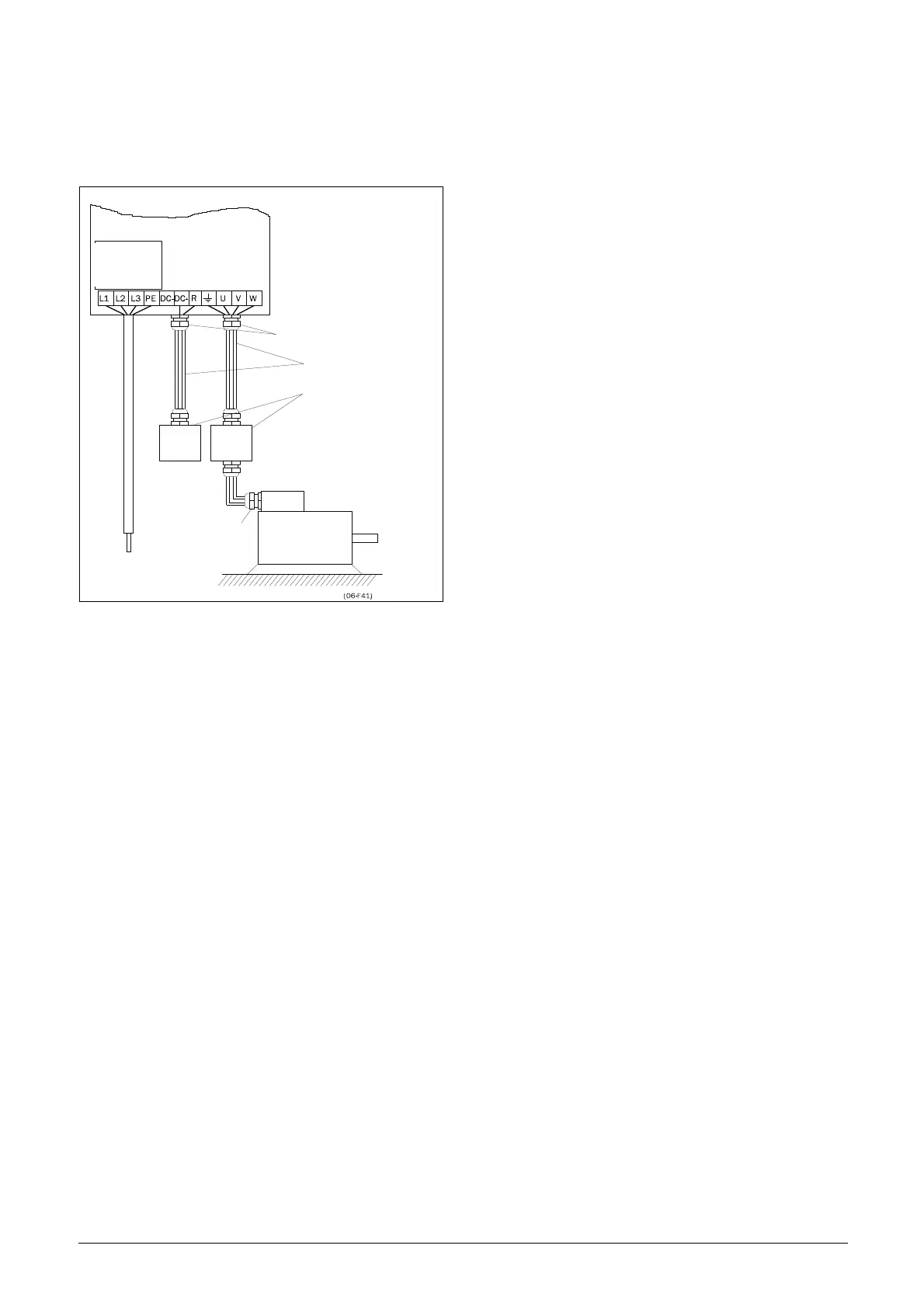

Fig. 43 shows an example when there is no metal mounting

plate used (e.g. if IP54 AC drives are used). It is important

to keep the “circuit” closed, by using metal housing and

cable glands.

Fig. 43 AC drive as stand alone.

Connect motor cables

1. Remove the cable interface plate from the AC drive

housing.

2. Put the cables through the glands.

3. Strip the cable according to table 15.

4. Connect the stripped cables to the respective motor

terminal.

5. Put the cable interface plate in place and secure

with the fixing screws.

6. Tighten the EMC gland with good electrical con-

tact to the motor and brake chopper cable screens.

Placing of motor cables

• Separate the power cables (AC drive, soft starter, output

coils, filters, magnetic switches, etc.) from the signal

cables (relay control circuit, PLC, sensors,

control PCBs, electronics, etc.).

• Keep the control cables as far from the power cables as

possible.

• If power cables and control cables must be laid close to

each other, try to ensure that they do not run parallel, at

least for a distance of no more than 300 mm (12 in).

If necessary, use a cable tray with a division or stack the

cable trays.

• Ensure that where power cables and control cables cross,

they do so at 90° to each other.

Long motor cables

If the connection to the motor is longer than 100 m

(330 ft)(for powers below 7.5 kW (10.2 hp)) please contact

CG Drives & Automation), it is possible that capacitive

current peaks will cause tripping at overcurrent. Using

output coils can prevent this. Contact the supplier for

appropriate coils.

Switching in motor cables

Switching in the motor connections is not advisable. In the

event that it cannot be avoided (e.g. emergency or

maintenance switches) only switch if the current is zero. If

this is not done, the AC drive can trip as a result of current

peaks.

Metal EMC cable

glands

Screened cables

Metal housing

Loading...

Loading...