Diagnostics and troubleshooting Deltabar PMD75B HART

62 Endress+Hauser

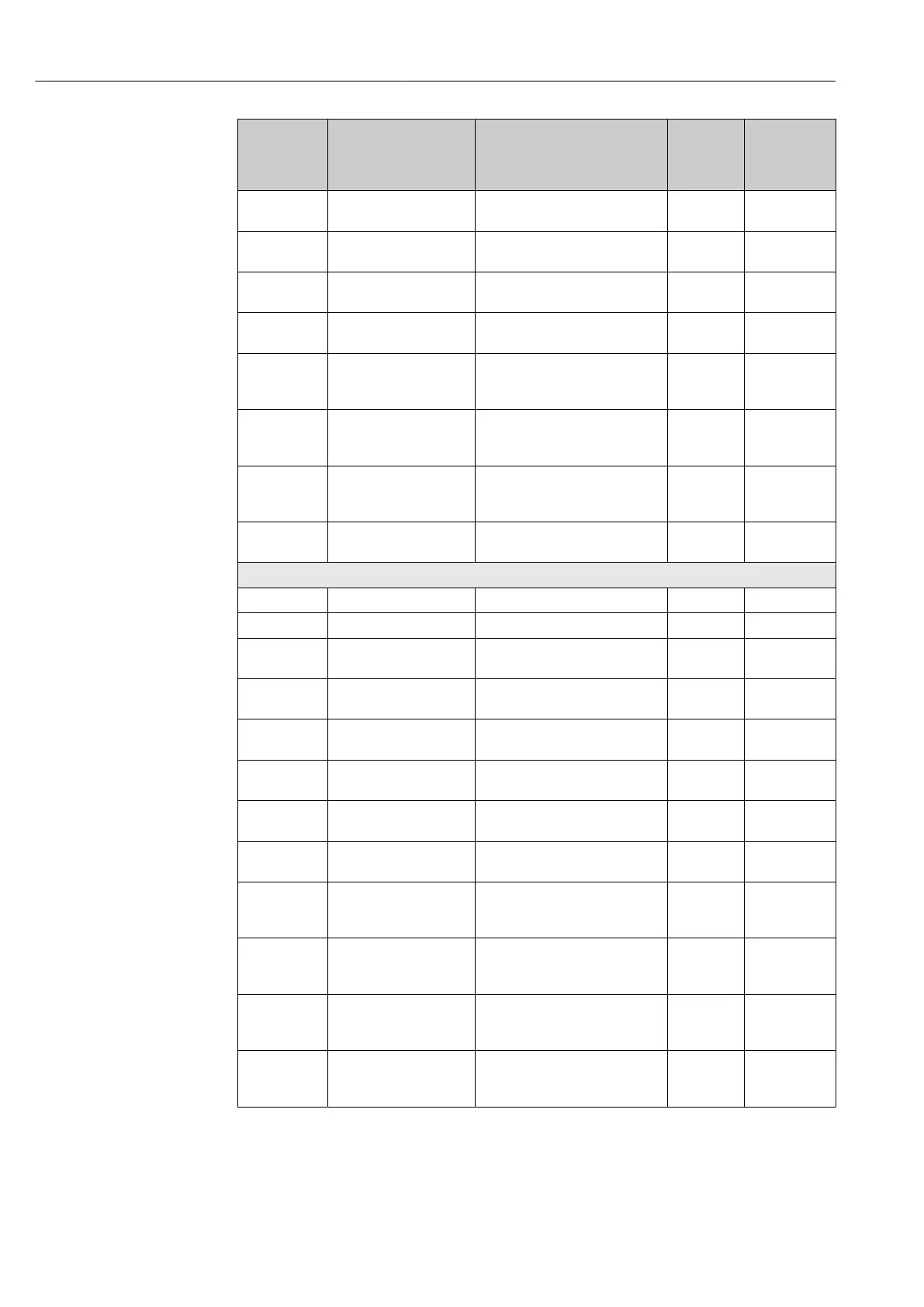

Diagnostic

number

Short text Remedy instructions Status

signal

[from the

factory]

Diagnostic

behavior

[from the

factory]

484 Failure mode simulation

active

Deactivate simulation C Alarm

485 Process variable

simulation active

Deactivate simulation C Warning

491 Current output

simulation active

Deactivate simulation C Warning

495 Diagnostic event

simulation active

Deactivate simulation C Warning

500 Process alert pressure 1. Check process pressure

2. Check configuration of process

alert

S Warning

1)

501 Process alert scaled

variable

1. Check process conditions

2. Check scaled variable

configuration

S Warning

1)

502 Process alert temperature 1. Check process temperature

2. Check configuration of process

alert

S Warning

1)

503 Zero adjustment 1. Check measuring range

2. Check position adjustment

M Warning

Diagnostic of process

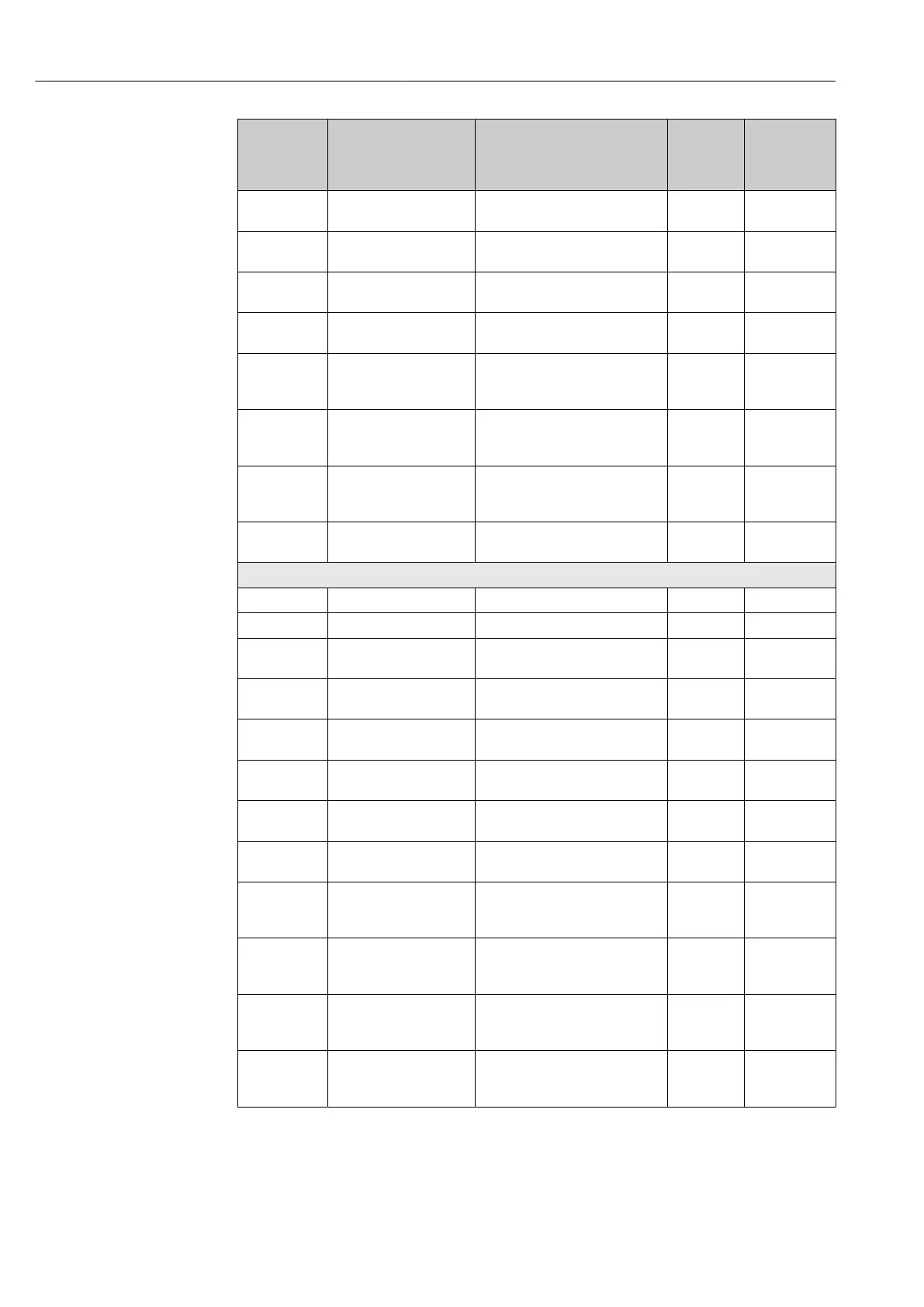

801 Supply voltage too low Increase supply voltage F Alarm

802 Supply voltage too high Decrease supply voltage S Warning

805 Loop current faulty 1. Check wiring

2. Replace electronics

F Alarm

806 Loop diagnostics 1. Check supply voltage

2. Check wiring and terminals

M Warning

1)

807 No Baseline due to insuf.

volt. at 20 mA

Increase supply voltage M Warning

822 Sensor temperature out

of range

1. Check process temperature

2. Check ambient temperature

S Warning

1)

825 Operating temperature 1. Check ambient temperature

2. Check process temperature

S Warning

841 Operating range 1. Check the process pressure

2. Check the sensor range

S Warning

1)

900 High signal noise

detected

1. Check impulse line

2. Check valve position

3. Check process

S Warning

1)

901 Low signal noise detected 1. Check impulse line

2. Check valve position

3. Check process

S Warning

1)

902 Min signal noise detected 1. Check impulse line

2. Check valve position

3. Check process

S Warning

1)

906 Out of range signal

detected

1. Process Information. No action

2. Rebuild baseline

3. Adapt signal range thresholds

C Warning

1)

1) Diagnostic behavior can be changed.

Loading...

Loading...