22

Enertech Global IOM, VS/VT Models, Rev A

Section 5: Unit Piping Installation

Interior Piping

All interior piping must be sized for proper ow rates

and pressure loss. Insulation should be used on all

inside piping when minimum loop temperatures

are expected to be less than 50°F. Use the table

below for insulation sizes with different pipe sizes.

All pipe insulation should be a closed cell and

have a minimum wall thickness of 3/8”. All piping

insulation should be glued and sealed to prevent

condensation and dripping. Interior piping may

consist of the following materials: HDPE, copper,

brass, or rubber hose (hose kit only). PVC is not

allowed on pressurized systems.

Table 3: Pipe Insulation

Piping Material Insulation Description

1” IPS Hose 1-3/8” ID - 3/8” Wall

1” IPS PE 1-1/4” ID - 3/8” Wall

1-1/4” IPS PE 1-5/8” ID - 3/8” Wall

2” IPS PD 2-1/8” ID - 3/8” Wall

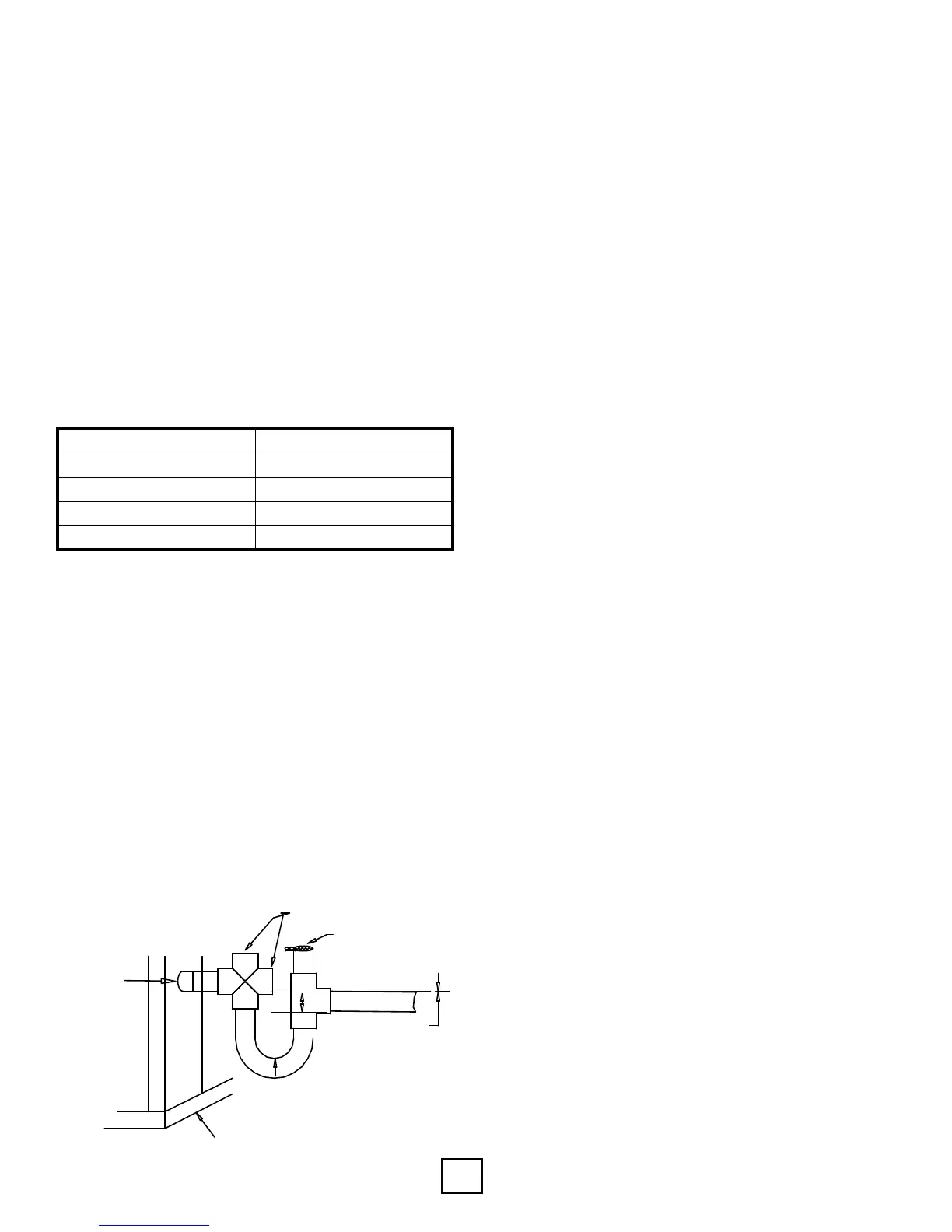

Condensation Drain Connection

Connect the EZ-Trap to the 3/4” equipment

condensate drain connection as shown in Figure 1.

The condensate line must be trapped a minimum of

1.0” as shown in the diagram. The condensate line

should be pitched away from the unit a minimum

of 1/4” per foot. The condensate line from the unit

drain connection to the P-trap should be sloped

downward. For more information on installing EZ-

Trap, see installation sheet that comes with the EZ-

Trap Kit. Always install the air vent after the trap.

Figure 1: Typical Condensation Drain Connection

Cleaning Holes (Capped)

1/4" per foot

Vent

Front of Unit

Unit Condensate

Drain Outlet

1.0”

Note: Connect the drain through the trap to the

condensation drain system in conformance to local

plumbing codes.

Part Number Description

ACDT1A - EZ-Trap ¾” Kit

ACDT2A - EZ-Trap 1” Kit (customer must provide a 1”

S x 3/4” Mips adapter)

Typical Pressurized Flow Center Installation

The ow centers are insulated and contain all

ushing and circulation connections for residential

and light commercial earth loops that require a

ow rate of no more than 20 gpm. 1-1/4” fusion x

1” double o-ring ttings (AGA6PES) are furnished

with the double O-ring ow centers for HDPE loop

connections. Various ttings are available for the

double O-ring ow centers for different connections.

A typical installation will require the use of a hose

kit. Matching hose kits come with double O-ring

adapters to transition to 1” hose connection.

Note: Threaded ow centers all have 1” FPT

connections. Matching hose kits come with the

AGBA55 adapter needed to transition from 1” FPT to

1” hose.

Typical Non-Pressurized Flow Center Installation

Standing column ow centers are designed to

operate with no static pressure on the earth loop.

The design is such that the column of water in the

ow center is enough pressure to prime the pumps

for proper system operation and pump reliability.

The ow center does have a cap/seal, so it is still a

closed system, where the uid will not evaporate. If

the earth loop header is external, the loop system

will still need to be ushed with a purge cart. The

non-pressurized ow center needs to be isolated

from the ush cart during ushing because the ow

center is not designed to handle pressure. Since this

is a non-pressurized system, the interior piping can

incorporate all the above-mentioned pipe material

options (see interior piping), including PVC. The ow

center can be mounted to the wall with the included

bracket or mounted on the oor as long as it is

properly supported.

Loading...

Loading...