26

Enertech Global IOM, VS/VT Models, Rev A

Flushing & Charging a Pressurized Flow Center

Once piping is completed between the unit, ow

center, and the earth loop, nal purging and

charging of the system is needed. A ush cart (at

least a minimum of 1.5 hp pump motor or larger)

is needed to achieve adequate ow velocity (2

fps in all piping) in the loop to purge air and debris

from the loop piping (unless the header manifold is

located inside and has isolation valves). All air and

debris must be removed from the system before

operation or pump failure could result. The ush

ports located on the ow center are access to the

piping system for the ush cart. See Figure 5 for

connection details.

The 3-way valves on the ow center include

direction indicators on the valves which determine

the ow path (see Figure 6). A 3/8” socket drive is

required to operate the 3-way valves. The valves

will turn in either direction, 360 degrees. Make sure

during this process that the valves are in the same

position so that air does not become trapped in the

system.

Water Quality

Even on a closed loop system water quality is an

issue. The system needs to be lled with clean water.

If the water on site has high iron content, high

hardness, or the PH is out of balance, premature

pump failure may result. Depending upon water

quality, it may need to be brought in from off site.

Removing Debris During Flushing

Most ow center or pump failures are a result of

poor water quality or debris. Debris entering the loop

during fusion and installation can cause noise and

premature pump failure. Enertech recommends a

double ush ltering method during purging. When

purging, use a 100 micron bag lter until air bubbles

are removed. Remove the 100 micron bag, replace

it with a 1 micron bag and restart the ushing.

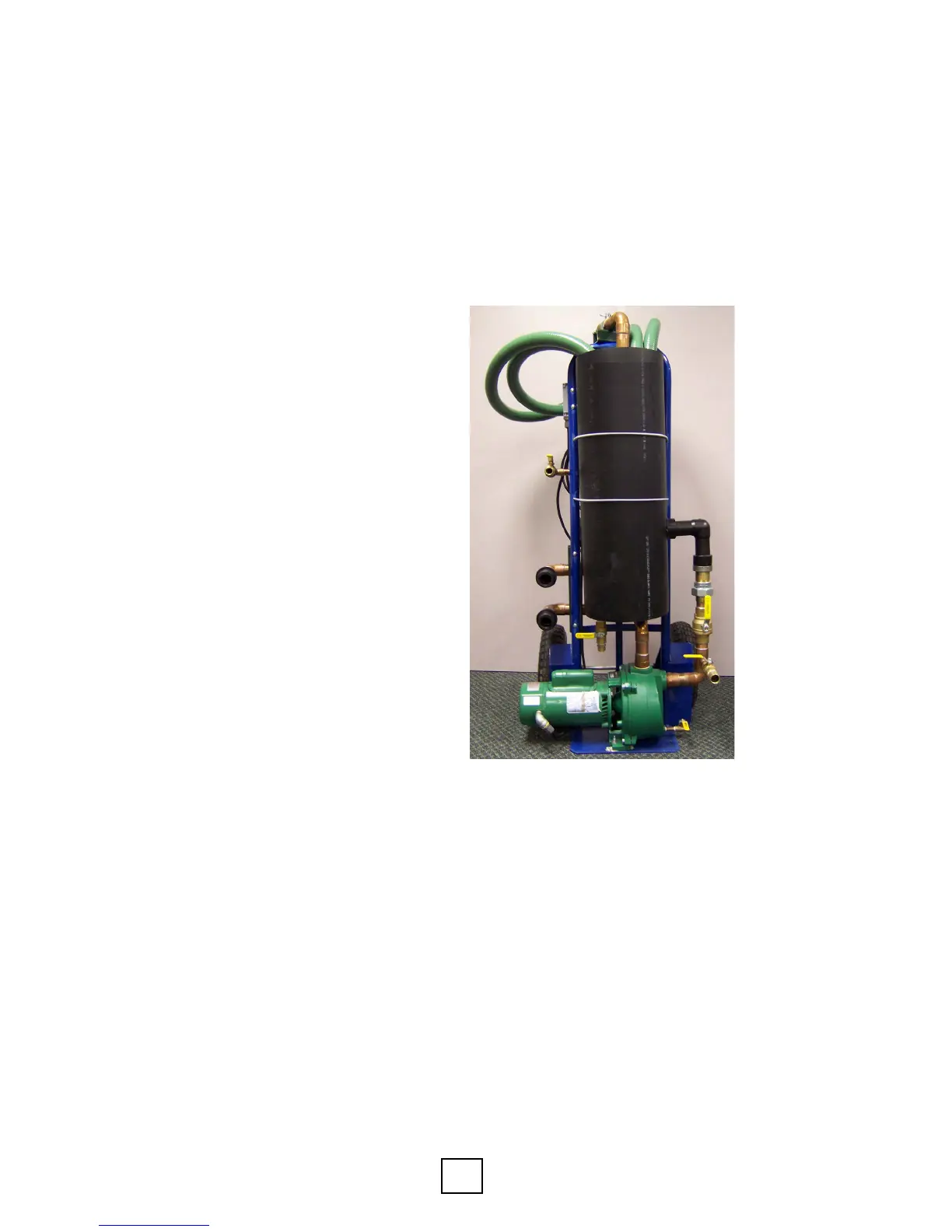

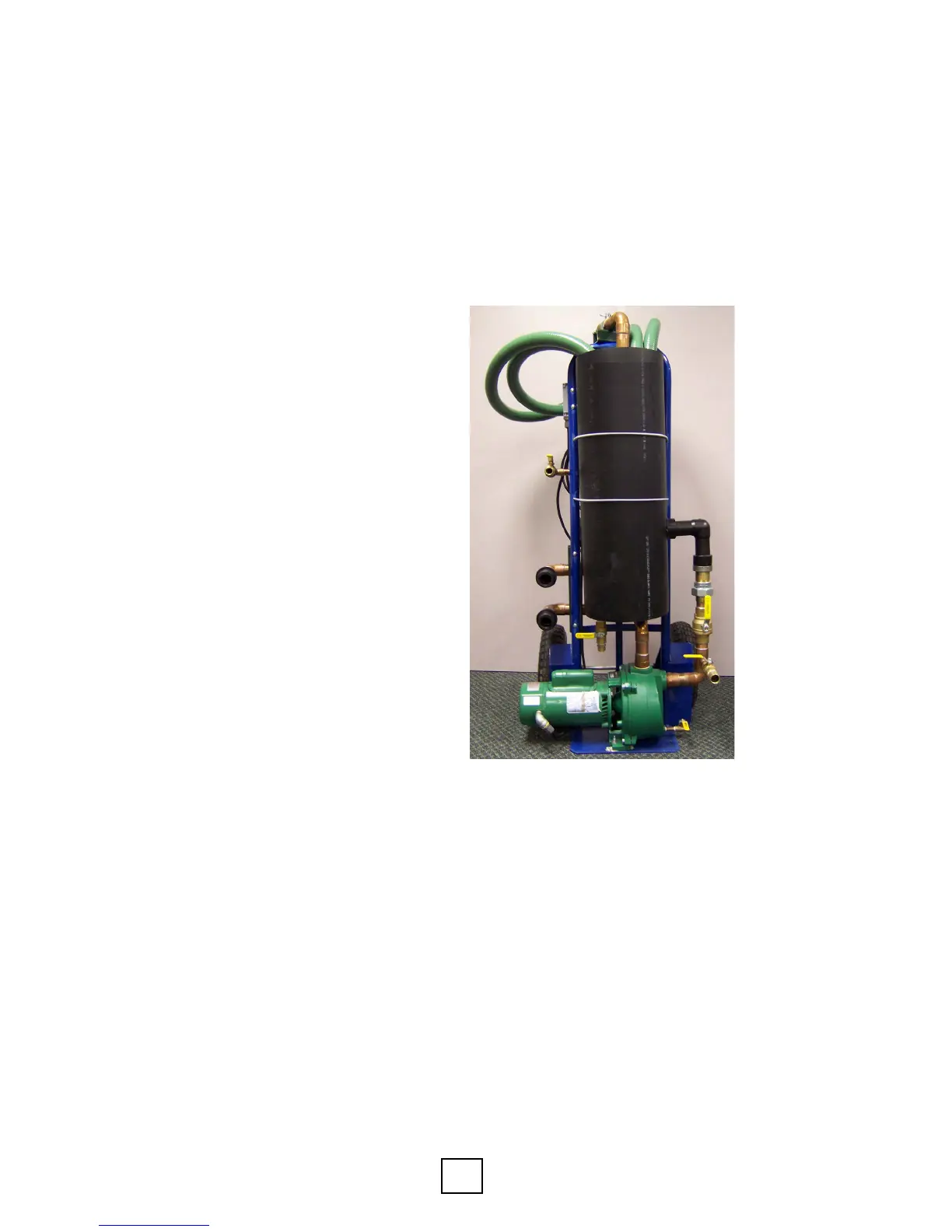

Flush Cart Design

The Enertech Manufacturing ush cart has been

designed to effectively and efciently ush the

earth loop and to facilitate injecting and mixing of

the antifreeze. The single most important element

in ow center reliability is the ability to remove all

the air and debris from the loop and to provide the

proper working pressure.

Features of the ush cart:

• Cylinder: HDPE, SDR15.5, 10” dia. (10 Gallons)

• Pump: Myers High Head QP15, 1.5hp, 115V

• Hose connections: Cam Lock quick connects -

1-1/2” hoses

• Hand Truck: 600lb rating with pneumatic tires

• Wiring: Liquid Tight metal on/off switch

• Tubing: SDR11 HDPE

• Connections: 2 - 3/4” connections for antifreeze

and discharge

• Drain: one on the pump and the tank

Step 1: Flushing the Earth Loop

• Connect ush cart hoses to ow center ush

ports using proper adapters #AGAFP.

• Connect water supply to hose connection on

return line of ush cart.

• Turn both 3-way valves on ow center to ush

ports and loop position.

• Turn on water supply (make sure water is of

proper quality).

• As the reservoir lls up, turn the pump on and off,

sucking the water level down. Do not allow the

water level to drop below intake tting to the

pump.

• Once the water level remains above the water

outlet in the reservoir leave the pump running

continuously.

• Once the water level stays above the “T” in

the reservoir, turn off the water supply (this also

allows observation of air bubbles).

Section 5: Unit Piping Installation

Loading...

Loading...