76

Enertech Global IOM, VS/VT Models, Rev A

Section 12: Troubleshooting

When any compressor bearing unit is connected to

a weak power supply, starting current will generate

a signicant “sag” in the voltage which reduces

the starting torque of the compressor motor and

increases the start time. This will inuence the rest of

the electrical system in the building by lowering the

voltage to the lights. This momentary low voltage

causes “light dimming”. The total electrical system

should be evaluated with an electrician and

HVAC technician. The evaluation should include

all connections, sizes of wires, and size of the

distribution panel between the unit and the utility’s

connection. The transformer connection and sizing

should be evaluated by the electric utility provider.

Note: Proper Power Supply Evaluation

⚠ CAUTION ⚠

CHECK COMPRESSOR AMP DRAW TO VERIFY

COMPRESSOR ROTATION ON THREE PHASE UNITS.

COMPARE AGAINST UNIT ELECTRICAL TABLES.

REVERSE ROTATION RESULTS IN HIGHER SOUND

LEVELS, LOWER AMP DRAW, AND INCREASED

COMPRESSOR WEAR. THE COMPRESSOR INTERNAL

OVERLOAD WILL TRIP AFTER A SHORT PERIOD OF

OPERATION.

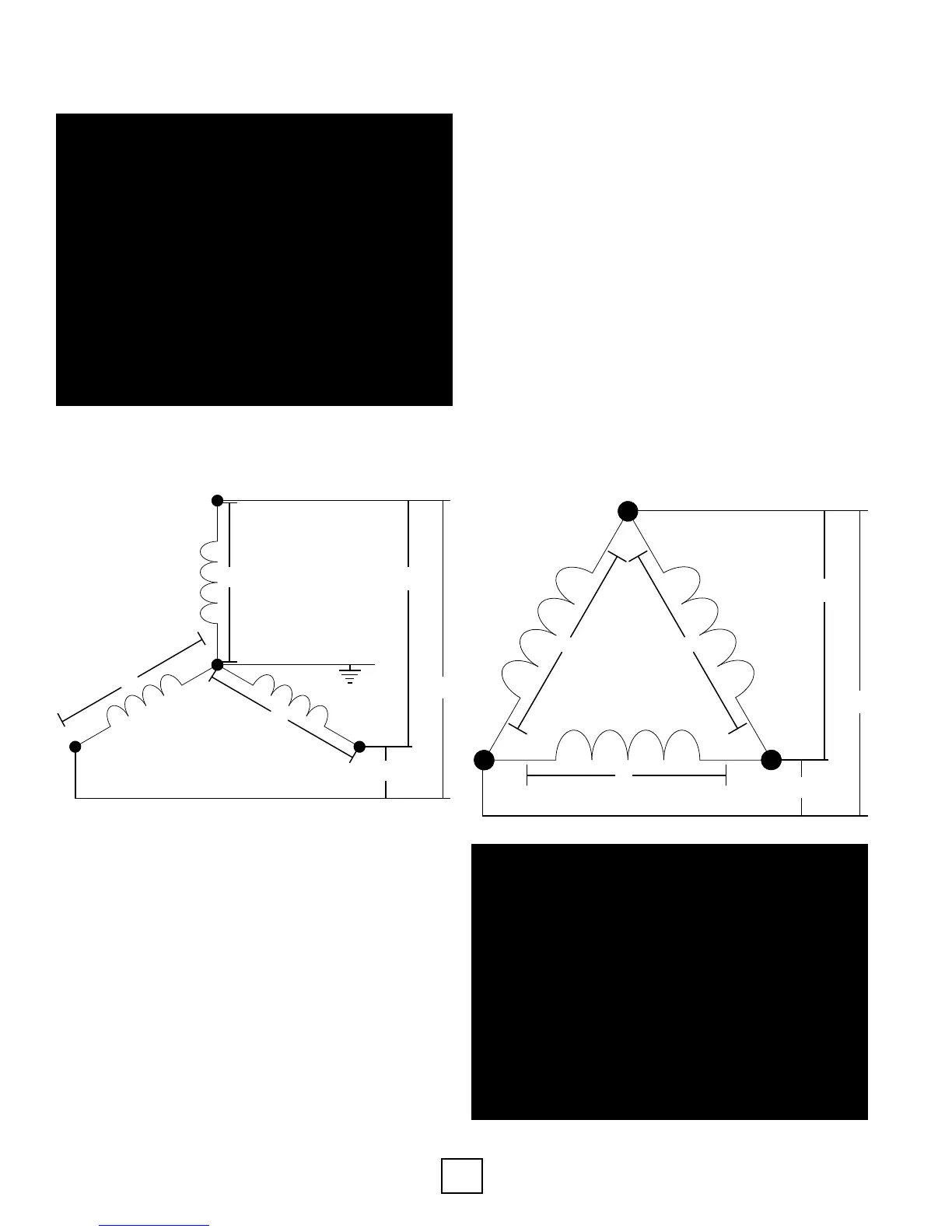

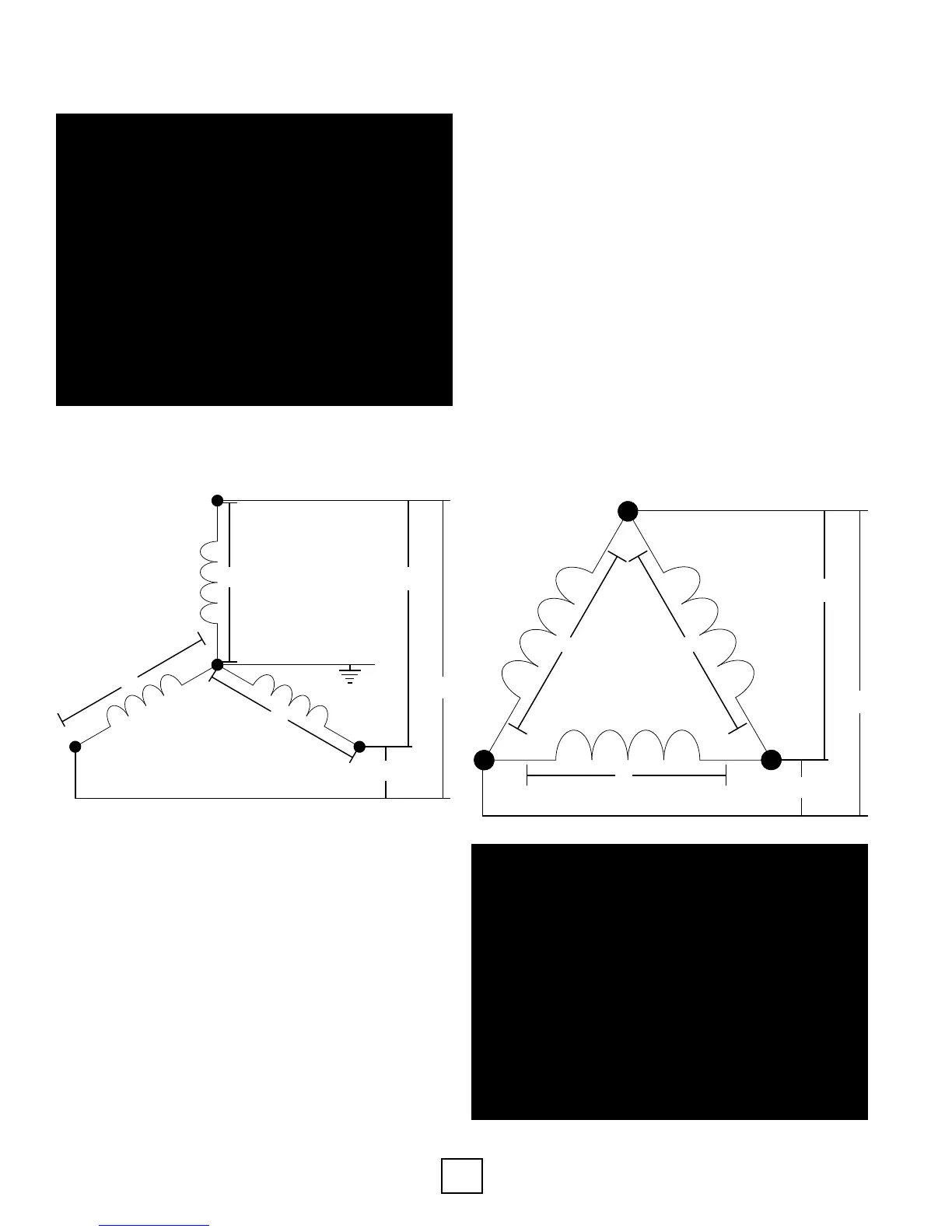

⚠ CAUTION ⚠

ALL VOLTAGE CODE “3” 460V UNITS UTILIZE A 277V

ECM MOTOR WHICH REQUIRES A NEUTRAL WIRE.

THE MOTORS ARE WIRED BETWEEN THE NEUTRAL

AND ONE HOT LEG OF THE CIRCUIT. SOURCE

WIRING MUST BE WYE (STAR) CONFIGURATION.

3-PHASE DELTA CONNECTIONS WILL NOT PROVIDE

THE CORRECT WIRING AND WILL CAUSE THE UNIT

NOT TO OPERATE.

Example 1: WYE (STAR) Electrical Circuit Example 2: DELTA Electrical Circuit

E

P

E

L

A

B

C

E

L

E

L

E

P

E

P

NEUTRAL OR

GROUND

E

P

E

L

A

B

C

E

L

E

L

E

P

E

P

NEUTRAL OR

GROUND

E

L

E

L

E

L

E

P

E

P

E

P

I

P

Unit Electrical Data

Loading...

Loading...