31

IOM, VS/VT Models, Rev A Enertech Global

Antifreeze Charging

Calculate the total amount of pipe in the system

and use Pipe Fluid Volume Table below to

calculate the amount of volume for each specic

section of the system. Add the entire volume

together, and multiply that volume by the proper

antifreeze percentage needed from the Antifreeze

Percentages by Volume Table below for the freeze

protection required in your area. Then, double

check calculations during installation with the

proper hydrometer and specic gravity chart to

determine if the correct amount of antifreeze was

added.

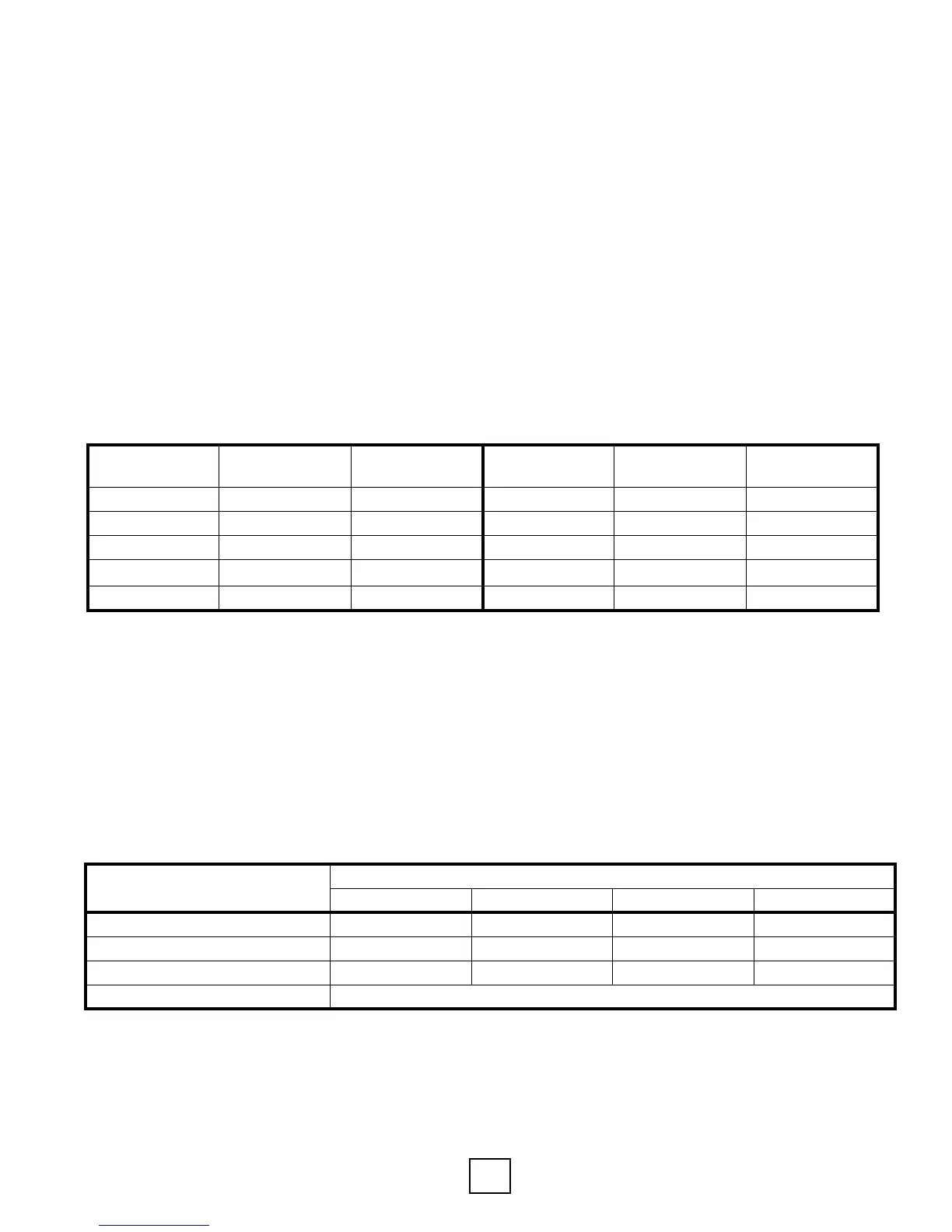

Pipe Fluid Volume

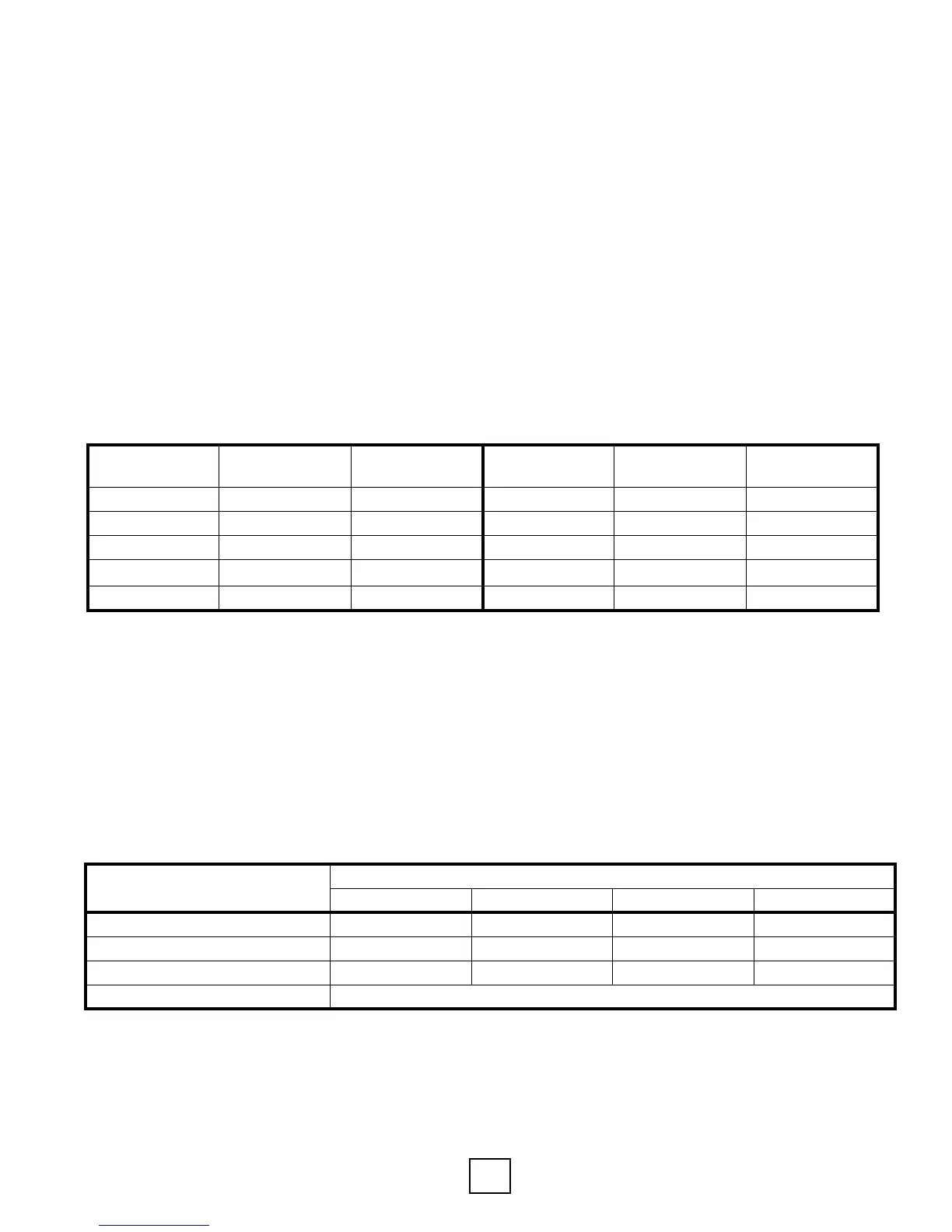

Antifreeze Percentages by Volume

Type of Antifreeze

Minimum Temperature for Freeze Protection

10°F (-12.2°C) 15°F (-9.4°C) 20°F (-6.7°C) 25°F (-3.9°C)

ProCool (Ethanol) 26% 23% 18% 13%

Methanol 21% 17% 13% 5%

Propylene Glycol* 30% 25% 20% 13%

Heat Transfer Fluid (HTF) Mix according to manufacturer’s directions on container label

Antifreeze solutions are shown in pure form - not premixed

HTF is a premixed Methanol solution

*Concentrations below 25-30% (consult manufacturer) typically require additional inhibitors.

Type Size

Volume Per 100ft

US Gallons

Type Size

Volume Per 100ft

US Gallons

Copper 1” CTS 4.1 HDPE .75” SDR11 3.0

Copper 1.25” CTS 6.4 HDPE 1” SDR11 4.7

Copper 1.5” CTS 9.2 HDPE 1.25” SDR11 7.5

HDPE 1.5” SDR11 9.8

HDPE 2” SDR11 15.4

Additional component volumes:

Unit coaxial heat exchanger = 1 Gallon

Flush Cart = 8-10 Gallons

10’ of 1” Rubber Hose = 0.4 Gallons

Section 5: Unit Piping Installation

Loading...

Loading...