43

IOM, VS/VT Models, Rev A Enertech Global

Section 9: Controls

Heating 3rd Stage, (Y1, Y2, W1, G) VT Units or

Heating 2nd Stage (Y1, W1, G) VS Units

When provided, the ECM fan remains at 100% of

2nd stage airow (CFM) level (based on DIP switch

settings), and the rst stage of electric resistance

heat is energized. Second stage of electric

resistance heat (W2) is energized ten minutes after

rst stage electric resistance heat (W1) is energized.

(W2 is only available with 10kW, 15kW and 20 kW

electric heaters)

Emergency Heat (W1, G) VT or VS Units

The fan is started immediately at 2nd stage airow

(CFM) level (based on DIP switch settings), and the

electric resistance heat is energized. Second stage

of electric heat (W2) is energized two minutes after

rst stage electric heat (W1) is energized. (W2 is

only available with 10kW, 15kW, and 20 kW electric

heaters)

Cooling Operation

The reversing valve is energized for cooling

operation. Terminal “O” from the thermostat is

connected to the reversing valve solenoid.

Cooling 1st stage (Y1, 0, G) VT or VS Units

The ECM fan immediately ramps up to 75% of 1st

stage (VT) or 2nd stage (VS) airow (CFM) level

(based on DIP switch settings), the Accessory (A)

terminal output is energized after the random start

timer (10s-20s) expires then rst stage compressor

and the loop pump(s) are energized 10 seconds

after “A”. The ECM fan adjusts to 100% airow

(CFM) level 90 seconds after the “Y1” input. VS units

with a PSC fan start at 100% airow (CFM) level

immediately upon the “G” input.

Cooling 2nd Stage (Y1, Y2, O, G) VT Units Only

The ECM fan adjusts to 2nd stage airow (CFM) level

(based on DIP switch settings), and the compressor

full load solenoid is energized.

Cooling, Dehumidication Mode VT or VS Units

When provided with an ECM fan motor, the

ECM fan control board includes two types of

dehumidication modes, Constant Dehumidication

mode, and On Demand Dehumidication (ODD).

If the ECM control board is set to Constant

Dehumidication mode, the ECM fan runs at normal

airow (CFM) in all heating stages, but all cooling

operation will be 85% of the current stage airow

(CFM) level (based on DIP switch settings). The

dehumidication mode lowers the airow (CFM)

through the evaporator coil, to improve latent

(dehumidication) capacity.

In ODD mode, a humidistat or a thermostat with a

dehumidication output (output must be reverse

logic -- i.e. it must operate like a humidistat) is

connected to the ODD terminal. When the module

receives a call for dehumidication, the fan runs at

85% of the current stage airow (CFM) in the cooling

mode. Otherwise, the airow is at the normal airow

(CFM) level. The signal is ignored in the heating

mode.

Fan Only VT or VS Units

When the ECM control module receives a “G”

call without a call for heating or cooling, the fan

operates at 50% of the full load airow (CFM) level

(based on DIP switch SETTINGS). VS units with a PSC

fan start at 100% airow (CFM) level immediately

upon the “G” input.

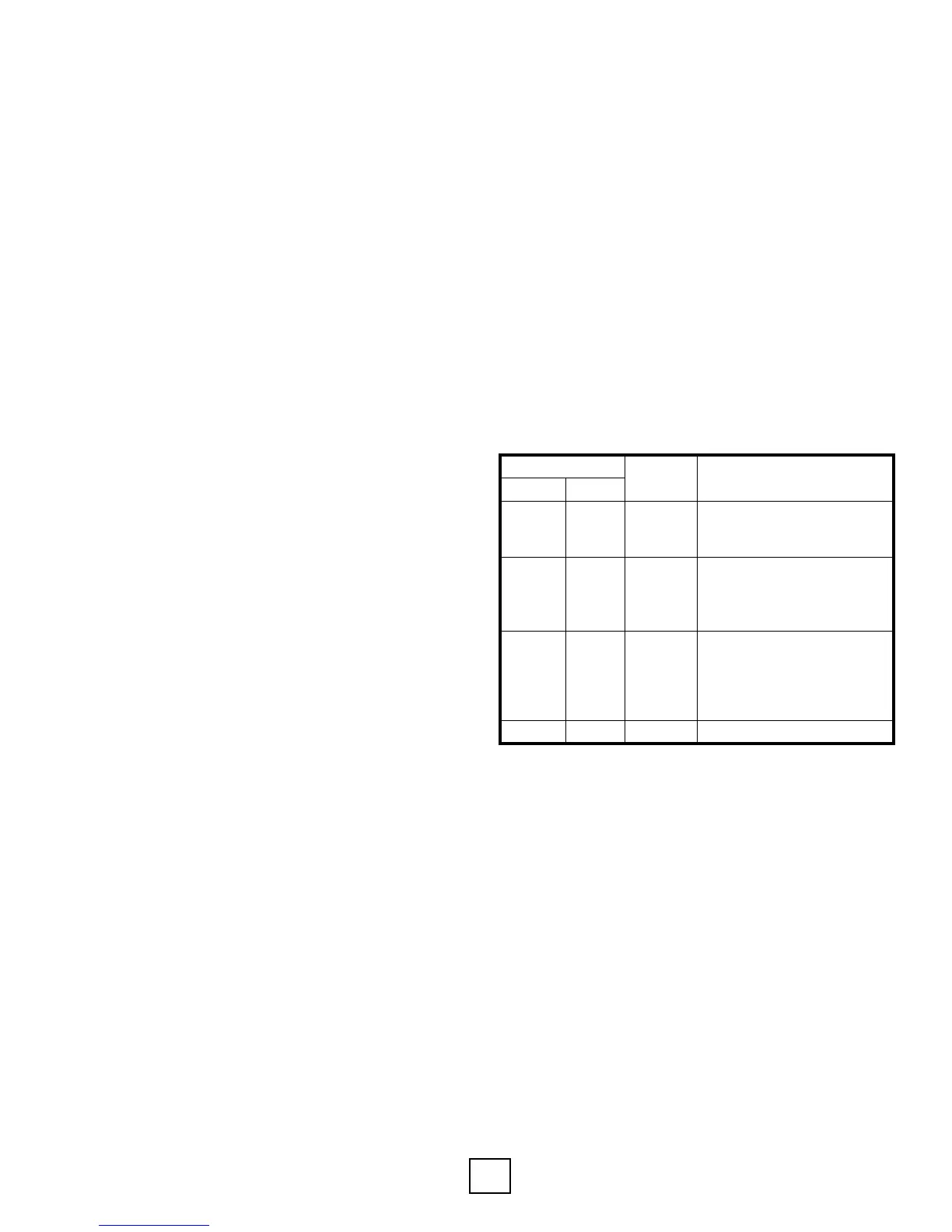

Dehumidication Mode Options

(ECM Fans Only)

DIP Switch

Mode Operation

S9 S10

ON OFF Normal

Dehumidication mode

disabled (normal Htg/Clg

CFM) - factory setting

OFF ON ODD

On Demand Dehumidication

mode (humidistat input at

terminal ODD) -

Humidistat required

OFF OFF

Constant

Dehum

Constant dehumidication

mode (always uses dehum

CFM for cooling and normal

CFM for heating) -

No humidistat required

ON ON Not Used Not an applicable selection

Notes:

1. To enter dehumidication mode, ODD input should be

0 VAC; for normal cooling CFM, ODD input should be

24VAC.

2. Heating CFM is not affected by dehumidication mode.

When in dehumidication mode, cooling CFM is 85% of

normal cooling CFM.

Loading...

Loading...