Maintenance 4. Joint #1 (Replacing the Motor)

100 S5 Rev.5

-check the

bolts to make sure that you have not forgotten to tighten any of

them.

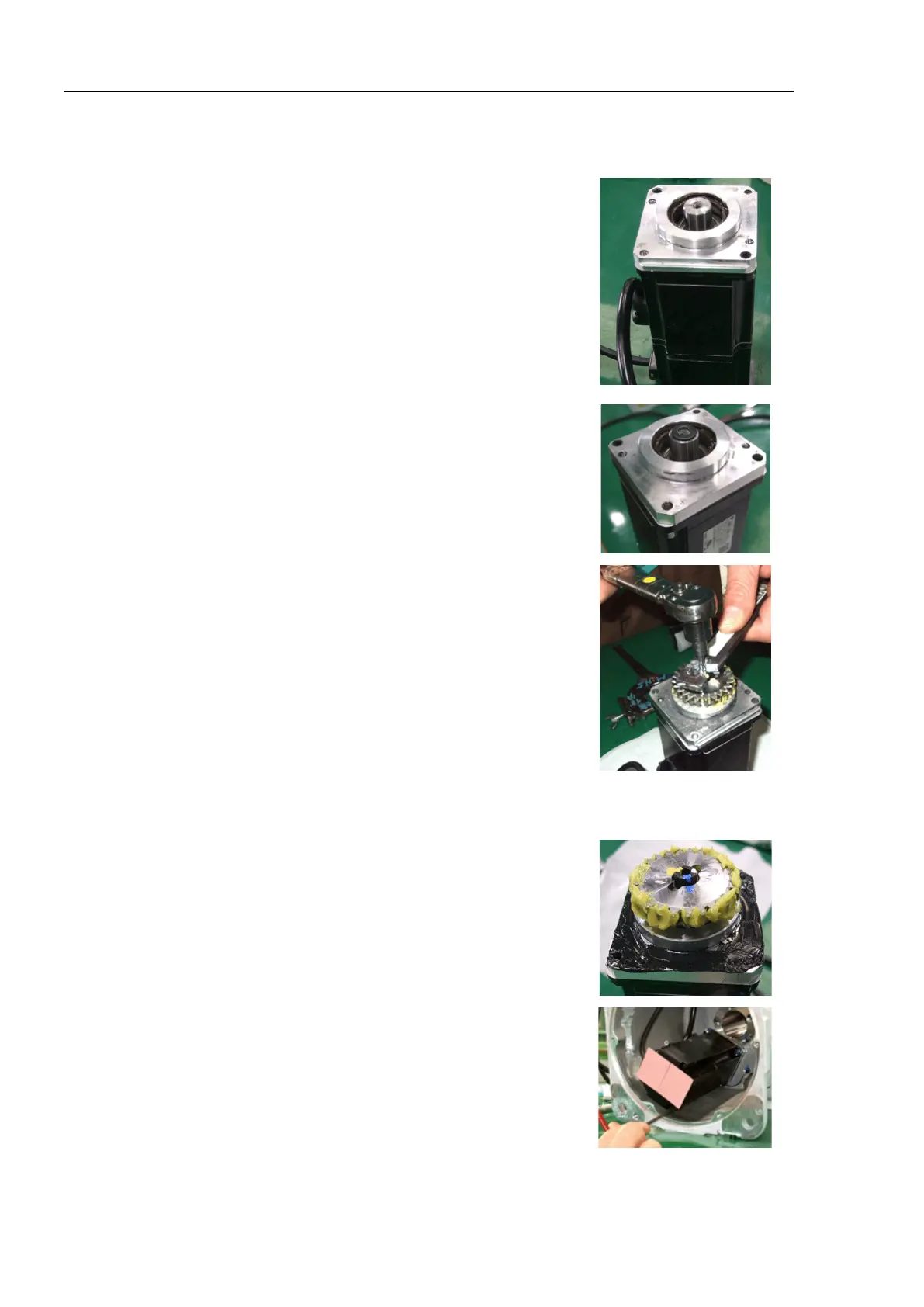

Mount the Joint #1 motor plate on the Joint #1

motor.

Hexagon socket head cap bolt

: 2-M4×14 (with disc spring, M4 washer)

Tightening torque: 2.8 N·m (0.29 kgf·m)

Be careful of direction of the Joint #1 motor plate.

Be careful not to damage the oil seal in the Joint

#1 motor plate.

Mount the gasket on the Joint #1 motor.

Mount the Joint #1 input gear.

Hexagon socket head cap bolt

: 1-M5×16 (with disc spring 2H-5)

Apply the liquid gasket.

Tightening torque: 10 N·m (1.02 kgf·m)

-

Hold the Joint #1 input gear as shown in the

picture while removing the bolt to prevent the g

from turning.

- Wipe excess

adhesive from other parts of the

motor with a wiping cloth treated with alcohol.

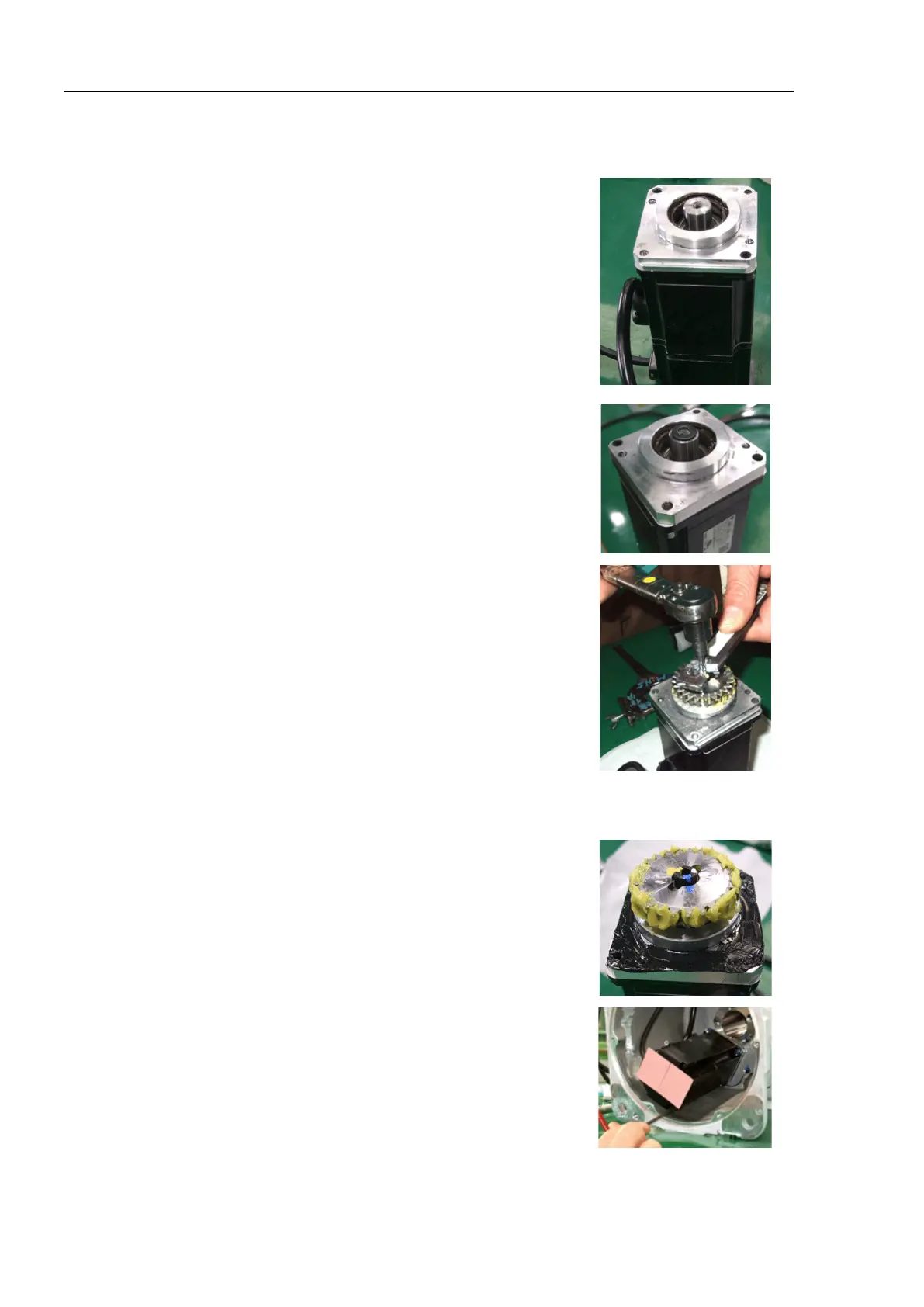

Apply the liquid gasket on surfaces of the Joint #1

motor plate and the Base.

Apply the grease for the reduction gear on the Joint

#1 input gear.

Grease: SK-1A

Mount the Joint #1 motor on the Base.

Hexagon socket head cap bolt

: 2-M4×25 (with disc spring 2H-4, M4 washer)

Apply the liquid gasket.

Tightening torque: 2.8 N·m (0.29 kgf·m)

6)

Connect the Joint #1 motor cables with the cables inside the

manipulator.

Loading...

Loading...