Maintenance 7. Joint #4 (Replacing the Motor)

S5 Rev.5 143

After parts have been replaced (motors, reduction gear units, timing belts, etc.), the

Manipulator cannot perform positioning properly because a mismatch exists between the

origin stored in each motor encoder and its corresponding origin stored in the Controller.

After replacing the parts, it is necessary to match these origins.

The process of aligning the two origins is called “Calibration”.

Refer to Maintenance 12. Calibration and follow the steps that pertain to the software you

are using to perform the calibration.

Maintenance

Parts

Grease for reduction gear

Arm #3 Cover.

efer to Maintenance 3.3 Arm #3 Cover.

Remove the bolts that secure the supporting plate

and then pull out the lead line from the

manipulator.

GT-SA bolt: 2-M4×10

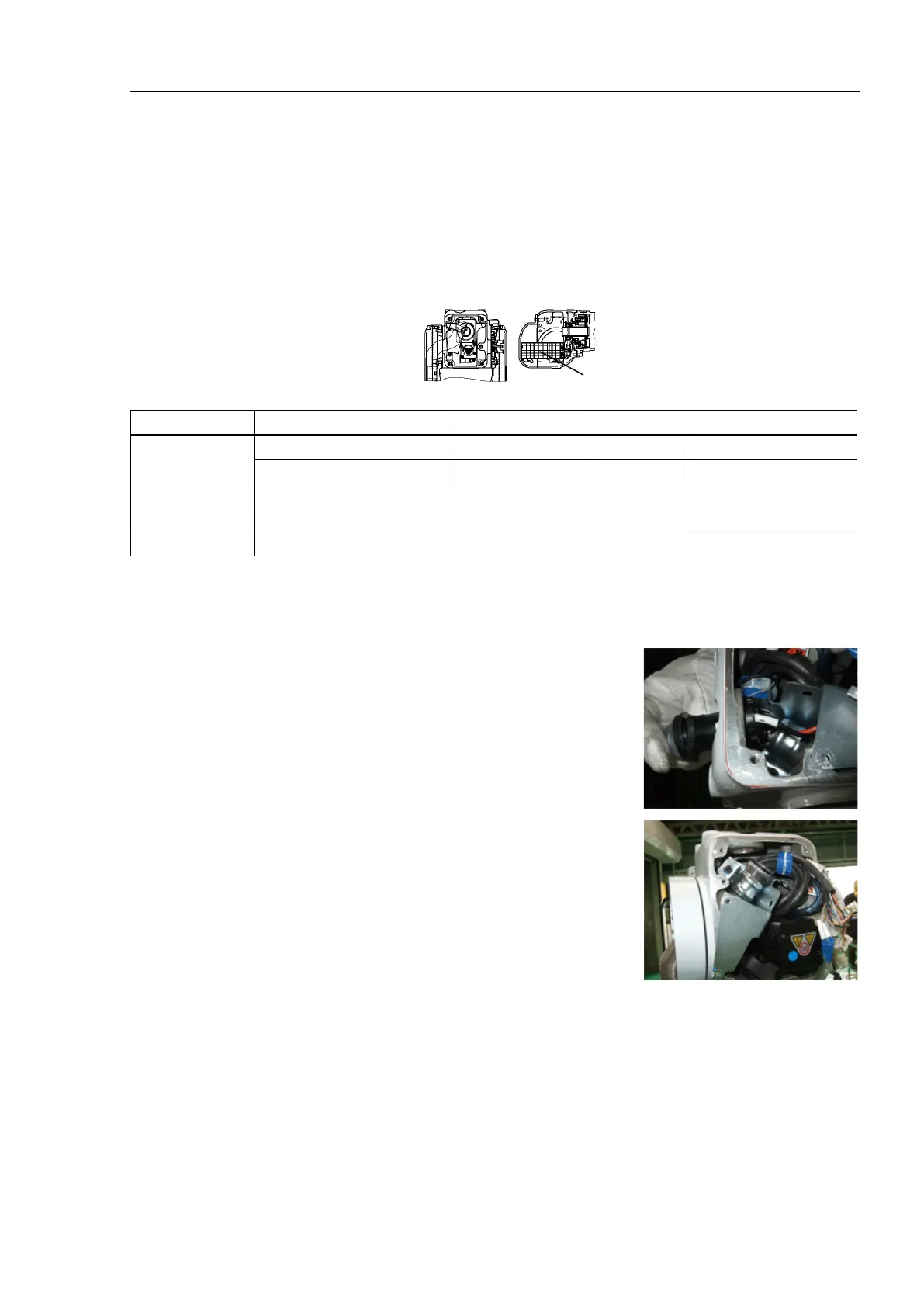

Connect the backup battery to the Joint #4 motor cable.

oint #4 motor cables from the cables inside the manipulator.

Remove the bolts and then remove the Joint #4 motor.

GT-SA bolt : 2-M3×12 (with M3 washer

Remove the bolts and then remove the pulley.

Hexagon socket head cap bolt : M3×12 (with disc spring 2H-3)

Loading...

Loading...