– 13 –

- Mounting counterbending die -

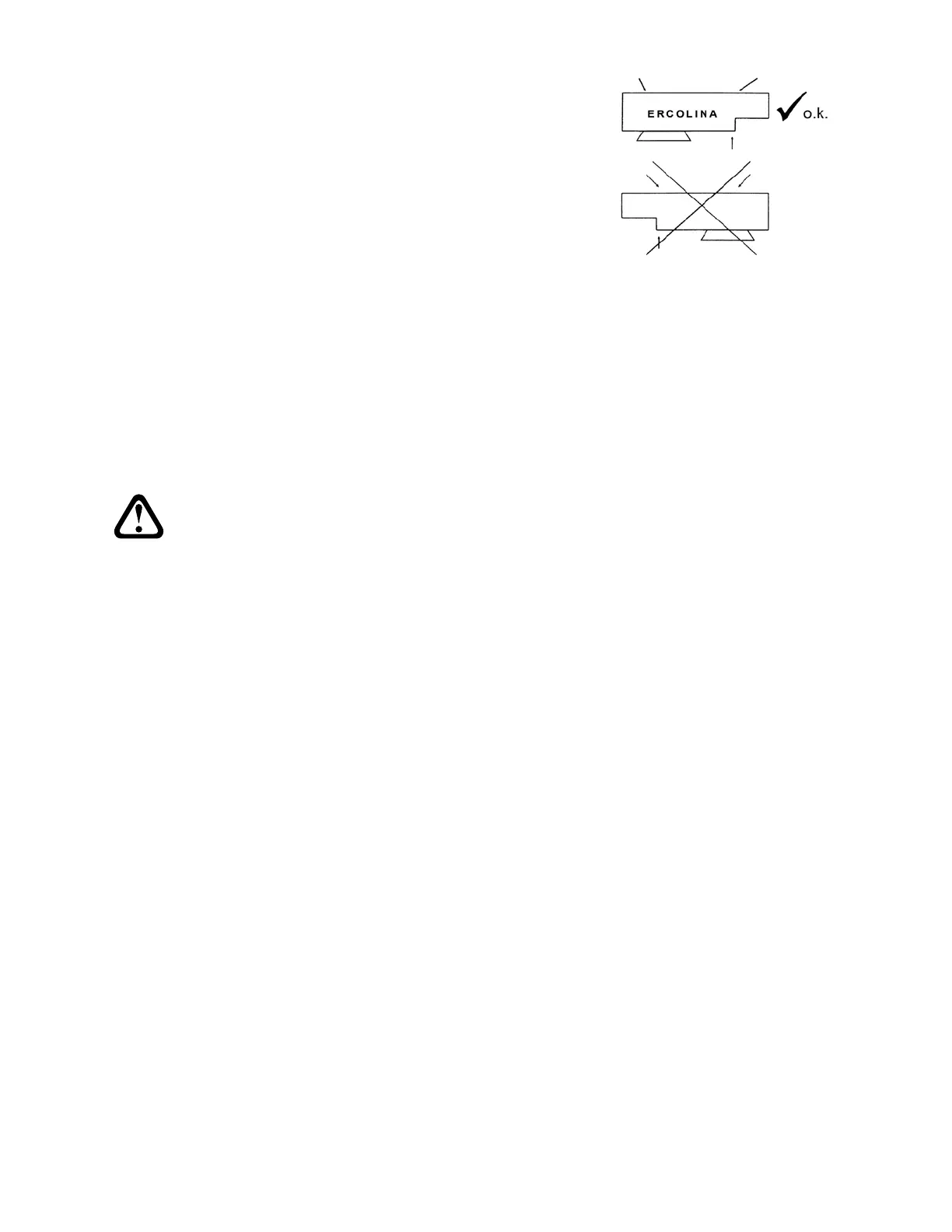

Ercolina

®

counterbending dies are designed for quick installation and

removal. Insert male dovetail located on back of counterbend die

into slot on counterbending die vise. Installed properly, the “Ercolina

®

”

logo will be facing the operator (see gure).

Counterbending dies are wear items - Replace as necessary to ensure bend quality. Counterbending die

should never contact center former when material is in former and tooling is in starting position.

- Counterbending die lubrication -

For best results counterbending dies should be kept well-lubricated with Ercolina

®

spray grease - #810.

Proper lubrication extends counterbend die life and improves bend quality.

Warning! When bending heavy wall proles and solids, standard counterbend die and vise must

be removed and replaced with a roller counterbend die. Attention: Failure to use roller style die on

heavy proles may result in machine damage.

- Mounting “roller” counterbending die -

When bending heavy wall proles or solid materials a roller counterbending die must be used. Remove

counterbend die vise assembly and place roller die onto machine tool post. With material in center former

advance roller die inward until material rests rmly between former and roller. Retract roller die approximately

2½″ from material (refer to FIG. 1 on next page). Warning: Never use roller die ush against material

– doing so will damage machine.

TB100/TB13003/2015

Loading...

Loading...