– 85 –

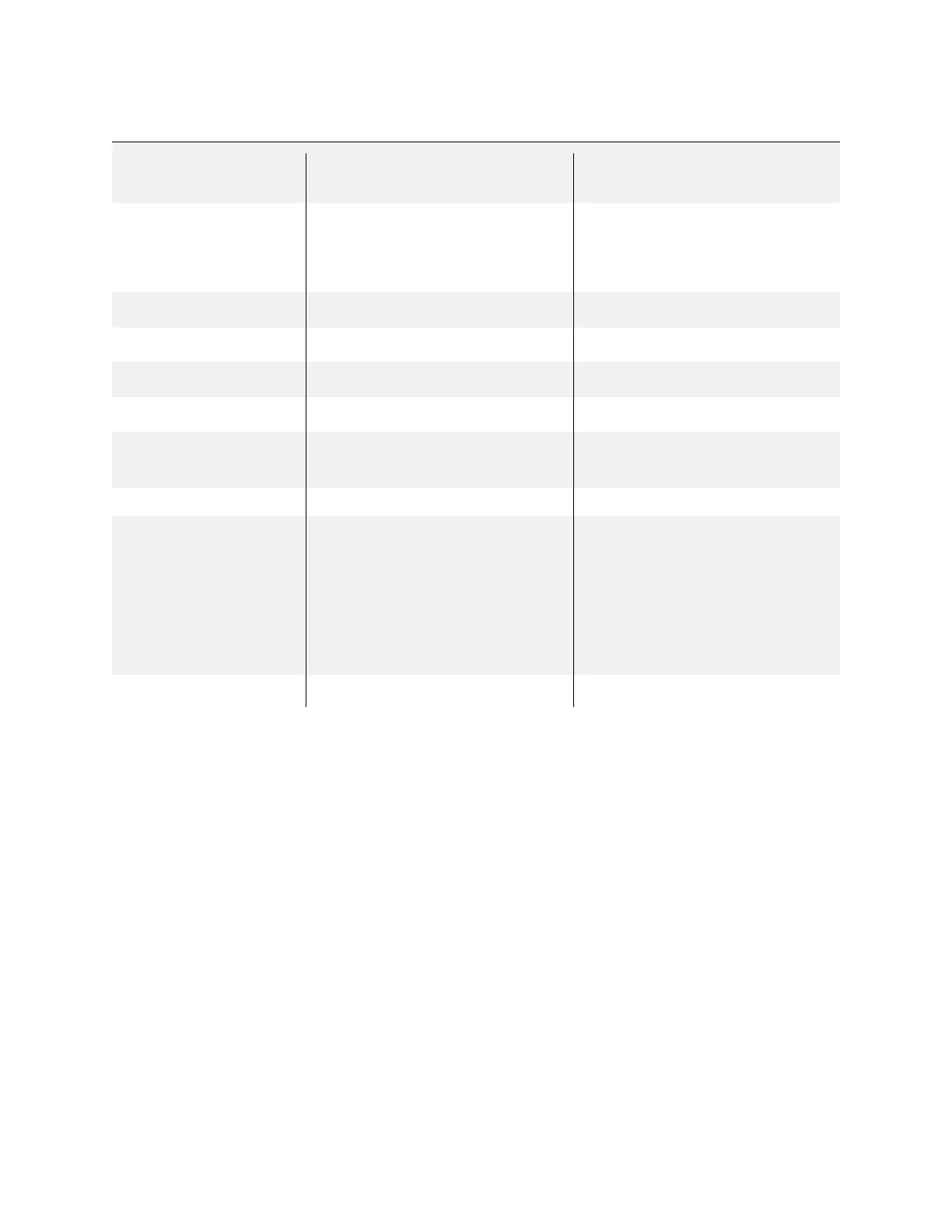

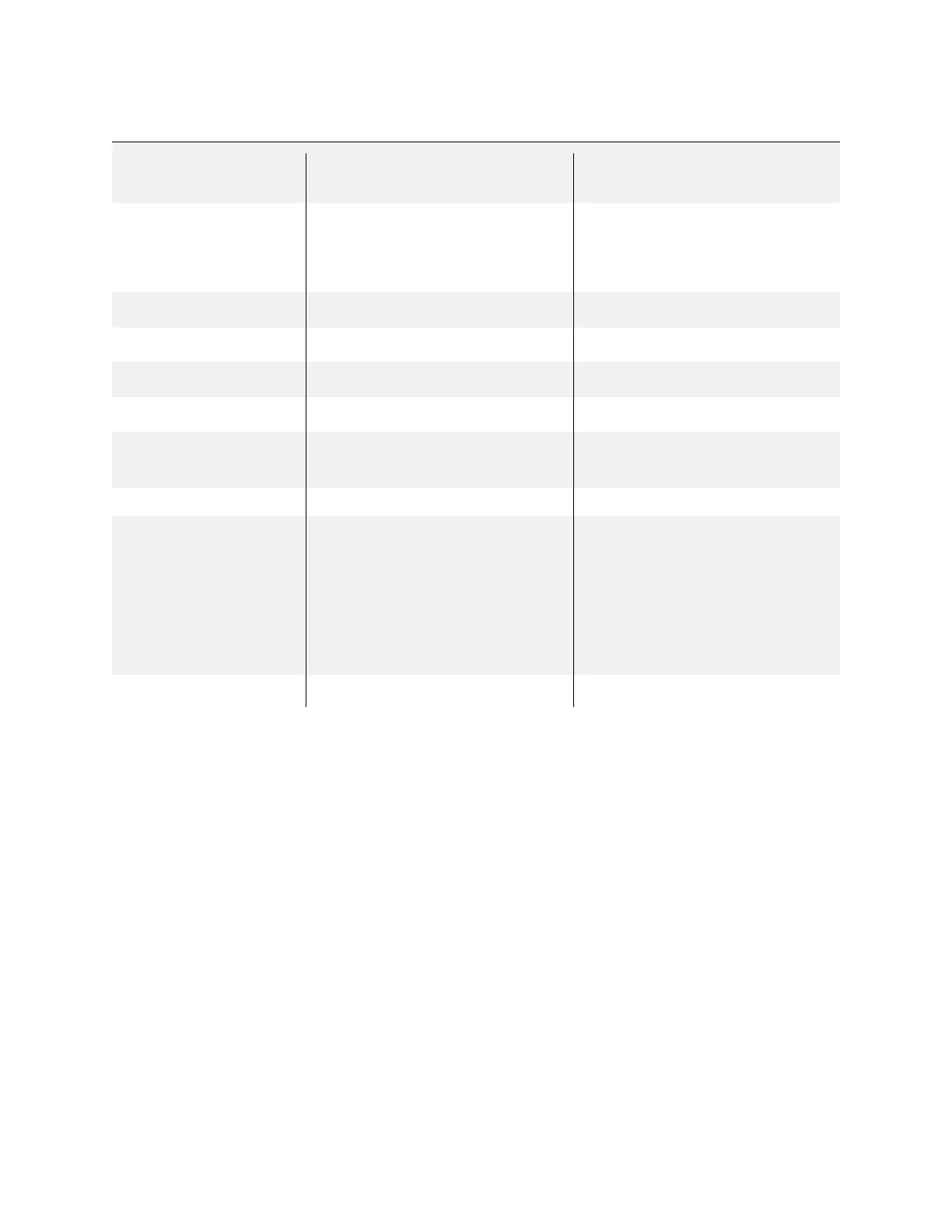

Problem Probable Cause Solution

Wrinkles on internal surface Material size Use correct size tube

Bending pressure too low Increase counter bending die pressure

Tube slips Material size Use correct size tube

Poor quality tubing, die pressure is too low Measure tubing and replace with quality

tube, increase die pressure

Tube cracks or breaks Poor tubing quality Change tube suppliers or composition

Poor bend quality Die and former are touching or deformed Die worn out, replace

Tube wrinkles or is deformed CLR is too tight for workpiece Increase the CLR

Workpiece is oval or deformed Too much pressure on die Decrease die pressure

Workpiece ends oval or Too much pressure on die Decrease die pressure and use adjustment

deformed screw

Machine goes into overload Material over capacity Use roller style counter bend die

Machine goes into overload Machine needs voltage calibration Enter system tests mode and view

voltage. Measure actual incoming line

voltage with hand held meter. If actual

voltage is different from voltage shown

on system display, use (plus and minus)

button on control pad to adjust display

to actual voltage.

Die wears prematurely Too much pressure, not enough lubricant Decrease pressure and use lubricant

Non-Mandrel Bending Trouble Shooting

TB100/TB13003/2015

Loading...

Loading...