– 86 –

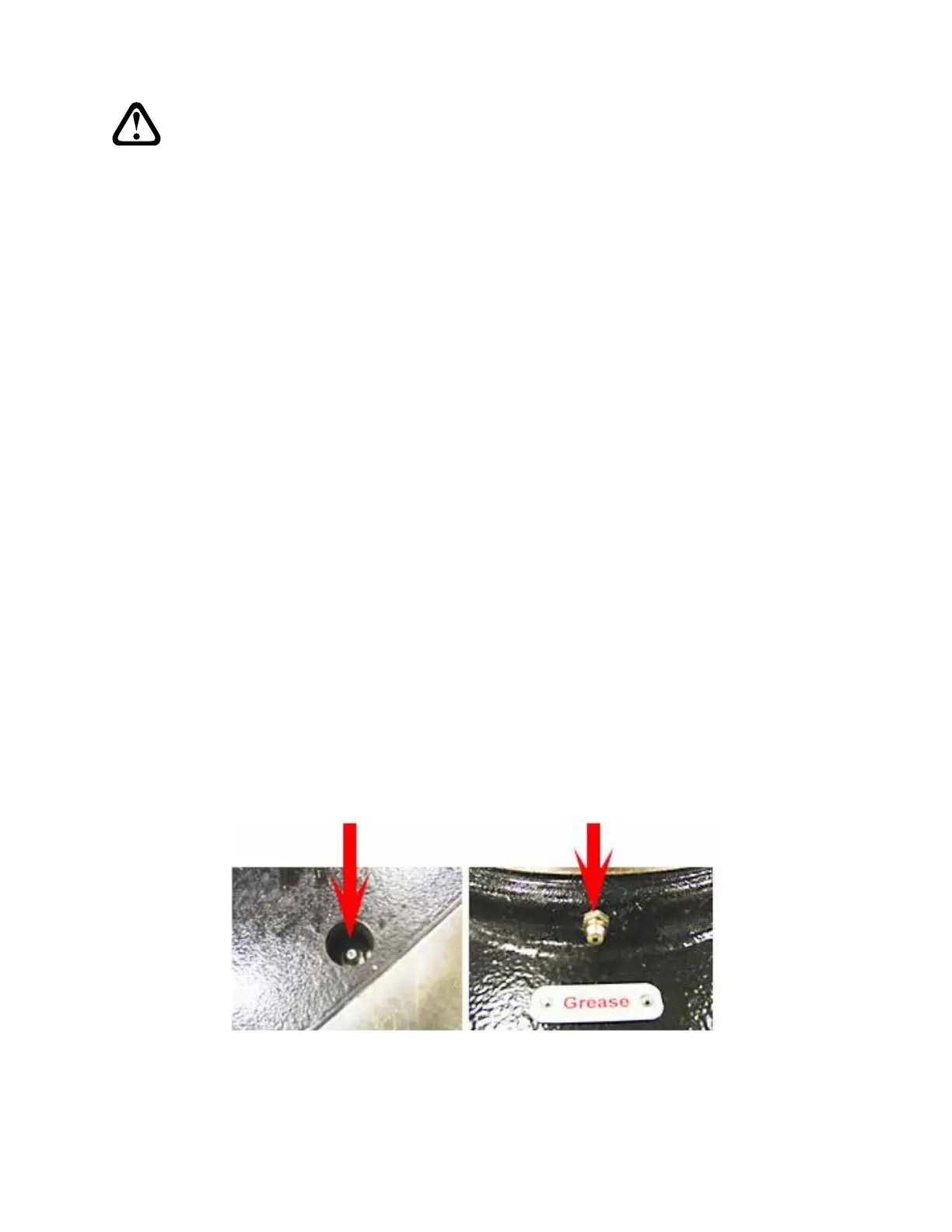

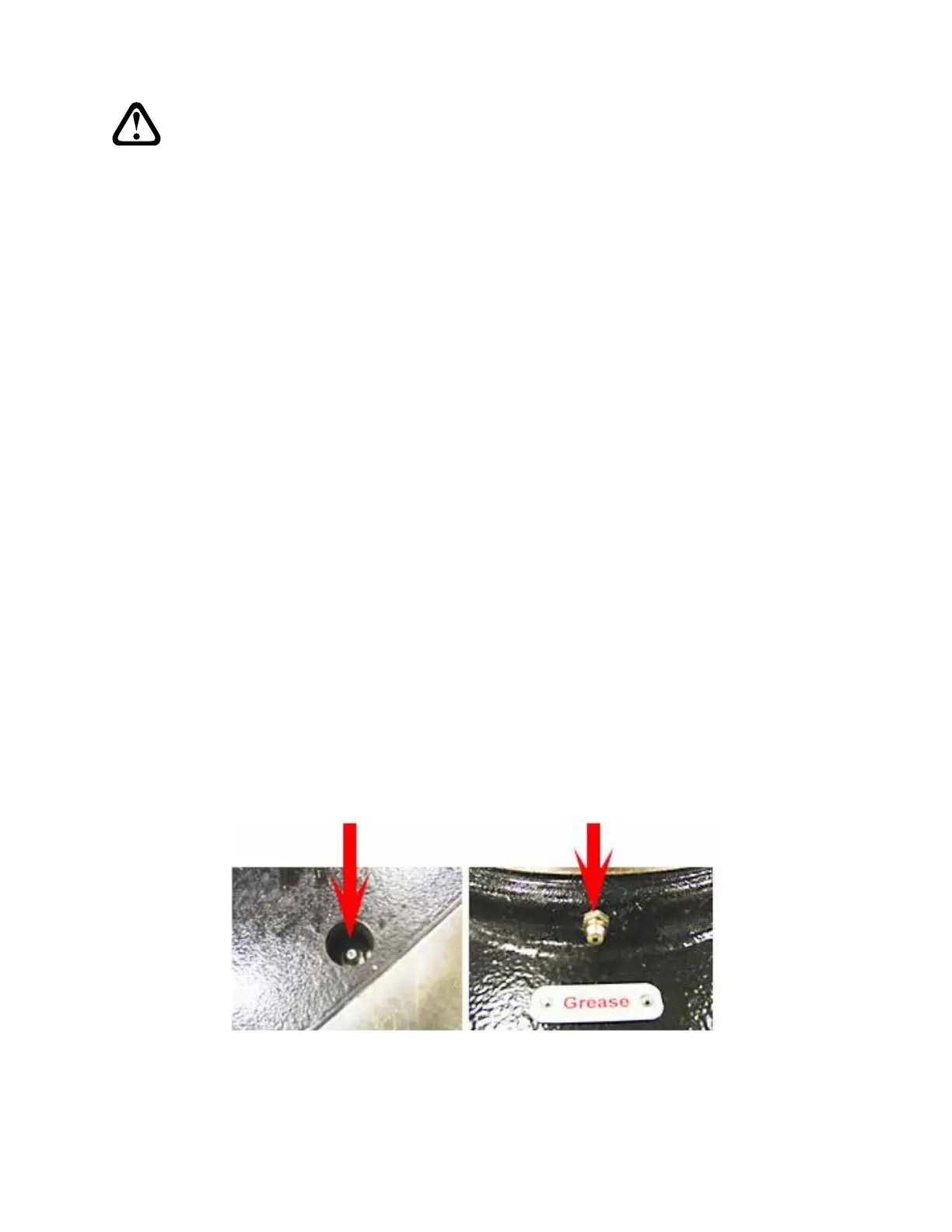

Don’t Forget The Grease!

Grease ttings are permanently installed by a threaded connection leaving a connection

that a grease gun attaches to. To prolong the life of your Ercolina bending machine it is

important to grease the zerks (ttings) every 40 work hours or 1,000 bends. WD-40 and

other penetrating oils actually break down the grease and can cause damage to your

machine.

Grease machine every 40 hours of operation

Use 1 oz. of Hi-Temp Grease NLGI No. 2 per tting.

Inadequate greasing can leave your gear case dry,

damaging the bushings in your machine.

VARIOUS TYPES AND LOCATIONS OF GREASE ZERKS

TB130 TB100

Routine Maintenance

CAUTION: Always disconnect machine from power source before performing maintenance

or adjustments.

Maintenance procedures should be performed by qualied personnel only.

1. Reduction gearbox: Check gearbox for leakage every 100 hours of operation.

2. Gears: Grease drive gears once every 3 months or sooner if under heavy use.

Recommended Grease: NLGI No. 2 EP / Rated NLGI GC-LB

03/2015TB100/TB130

Loading...

Loading...