– 79 –

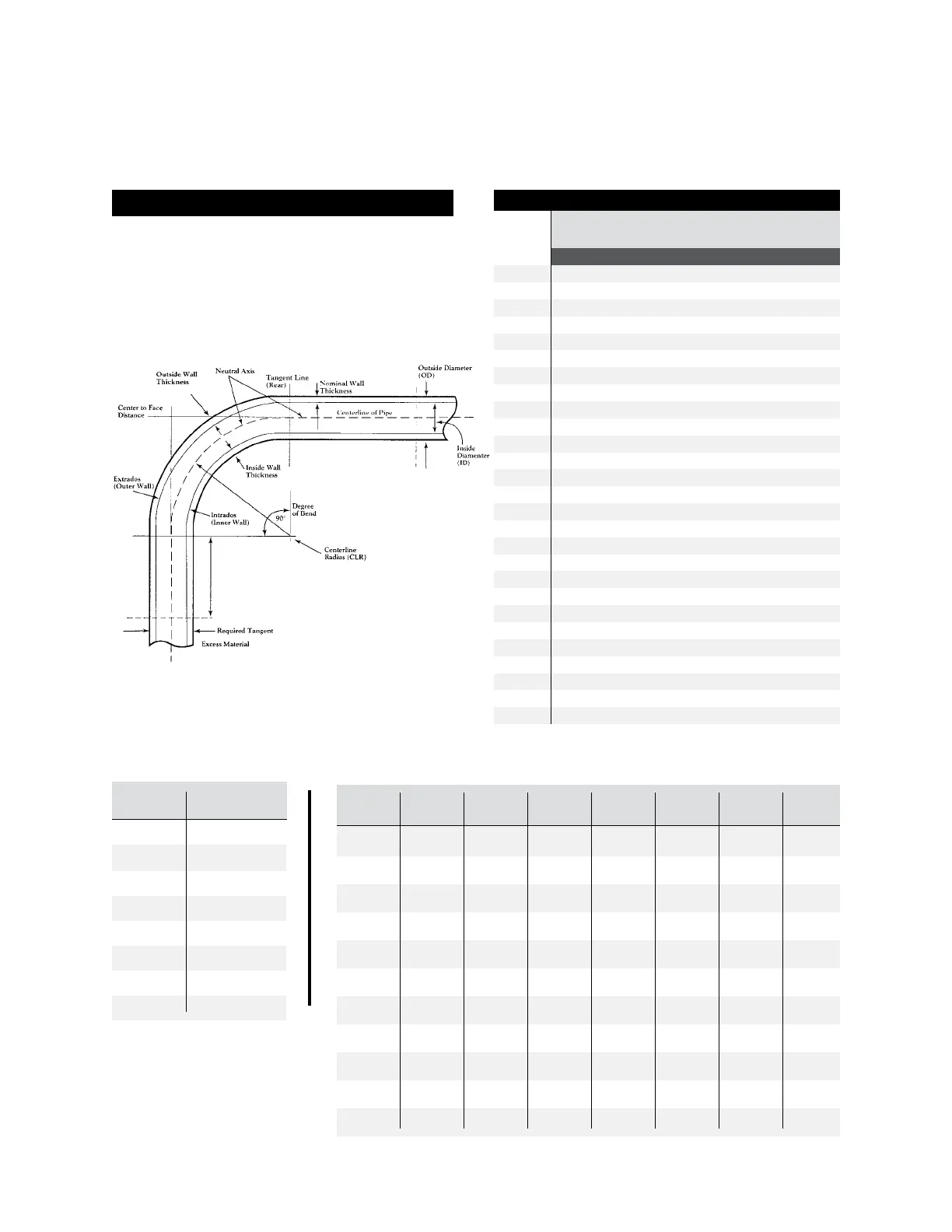

Commercial pipe and wall thickness

Nominal Outside Schedule Schedule Schedule Schedule Schedule XX

Size Dia. 5 10 40 80 160 Strong

⅛ .405 .049 .068 .095

¼ .540 .065 .088 .119

⅜ .675 .065 .091 .126

½ .840 .065 .083 .109 .147 .188 .294

¾ 1.050 .065 .083 .113 .154 .219 .308

1 1.315 .065 .109 .133 .179 .250 .358

1¼ 1.660 .065 .109 .140 .191 .250 .382

1½ 1.900 .065 .109 .145 .200 .281 .400

2 2.375 .065 .109 .154 .218 .344 .436

2½ 2.875 .083 .120 .203 .276 .375 .552

3 3.500 .083 .120 .216 .300 .438 .600

Tube Equivalent

gauge in inches

10 .134

11 .120

12 .109

13 .095

14 .083

16 .065

18 .049

20 .035

Radius x Degree of Bend x .0175 = Length

Material Consumption

for Bend Angle

To calculate total pipe length, add distance

from end of pipe to the first bend, plus first

bend arc length, plus distance to second bend.

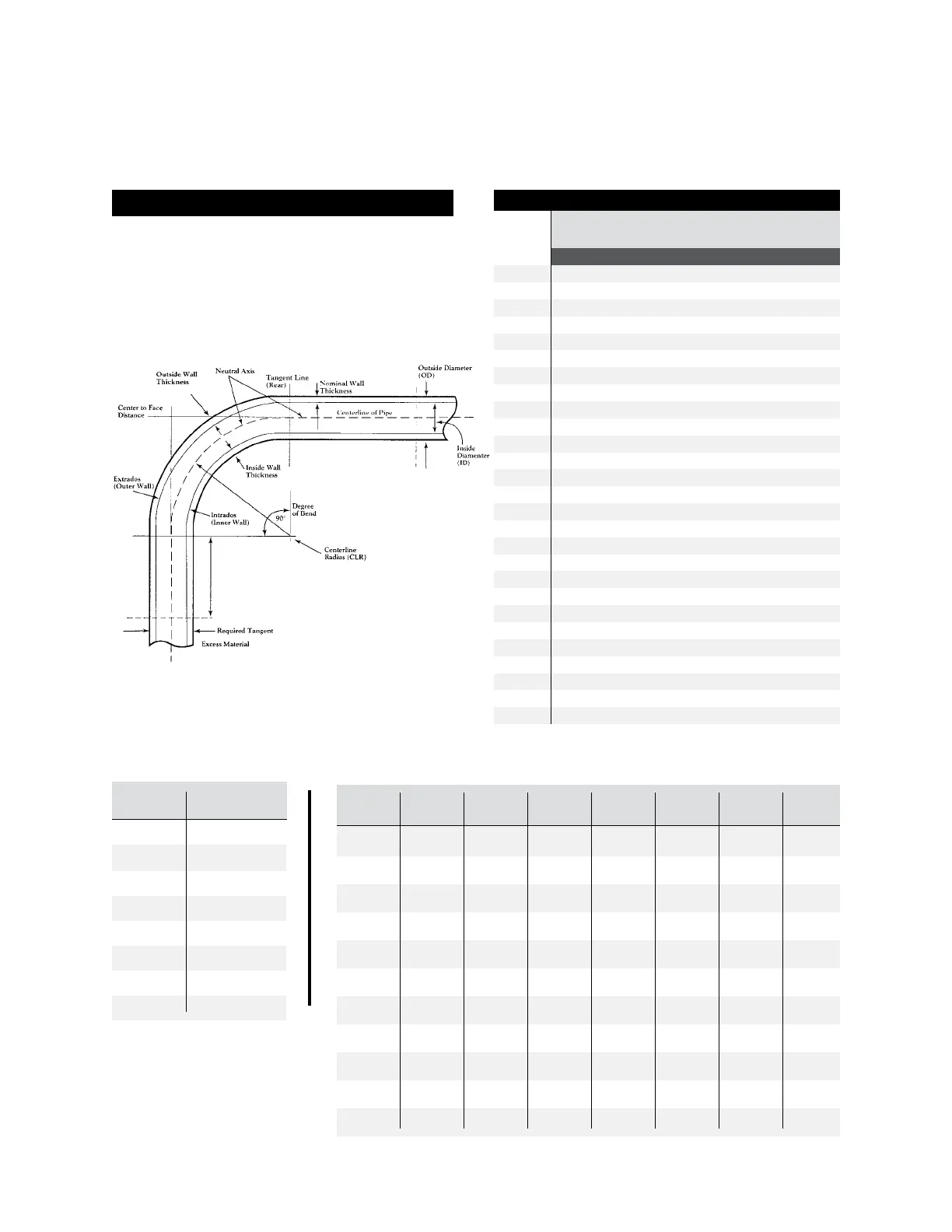

Rotary Draw Bend Reference Information

The following information should be used as a guideline only, exact material consumption may vary.

Pipe Size and Centerline Radius

½″ ¾″ 1″ 1¼″ 1½″ 2″

1.8 2.2 2.6 3.5 3.9 5.9

Material Consumption Guideline

5 .16 .19 .23 .31 .34 .51

10 .31 .38 .45 .61 .68 1.0

15 .47 .58 .68 .92 1.0 1.5

20 .63 .77 .91 1.2 1.3 2.1

25 .79 .96 1.1 1.5 1.7 2.6

30 .97 1.1 1.3 1.8 2.0 3.1

35 1.1 1.3 1.5 2.1 2.4 3.6

40 1.2 1.5 1.8 2.4 2.7 4.1

45 1.4 1.7 2.0 2.7 3.0 4.6

50 1.5 1.9 2.2 3.0 3.4 5.2

55 1.7 2.1 2.5 3.3 3.7 5.7

60 1.8 2.3 2.7 3.6 4.0 6.2

65 2.0 2.5 2.9 3.9 4.4 6.7

70 2.2 2.6 3.1 4.2 4.7 7.2

75 2.3 2.8 3.4 4.5 5.1 7.7

80 2.5 3.0 3.6 4.8 5.5 8.3

85 2.6 3.2 3.8 5.1 5.8 8.8

90 2.8 3.4 4.0 5.5 6.1 9.3

100 3.1 3.8 4.5 6.8 6.1 10.3

110 3.4 4.2 4.9 6.7 7.4 11.4

120 3.7 4.6 5.4 7.3 8.1 12.4

130 4.0 4.9 5.9 7.9 8.8 13.4

140 4.4 5.3 6.3 8.5 9.5 14.5

150 4.7 5.7 6.8 9.1 10.2 15.5

160 5.0 6.1 7.2 9.7 10.8 16.5

170 5.3 6.5 7.7 10.3 11.5 17.6

180 5.6 6.9 8.1 11.0 12.2 18.6

Material Required for

Rotary Draw Bends in Pipe

Angle

of

Bend

TB100/TB13003/2015

Loading...

Loading...