6 Description of M201 control

6/6

6.7 Further Functions

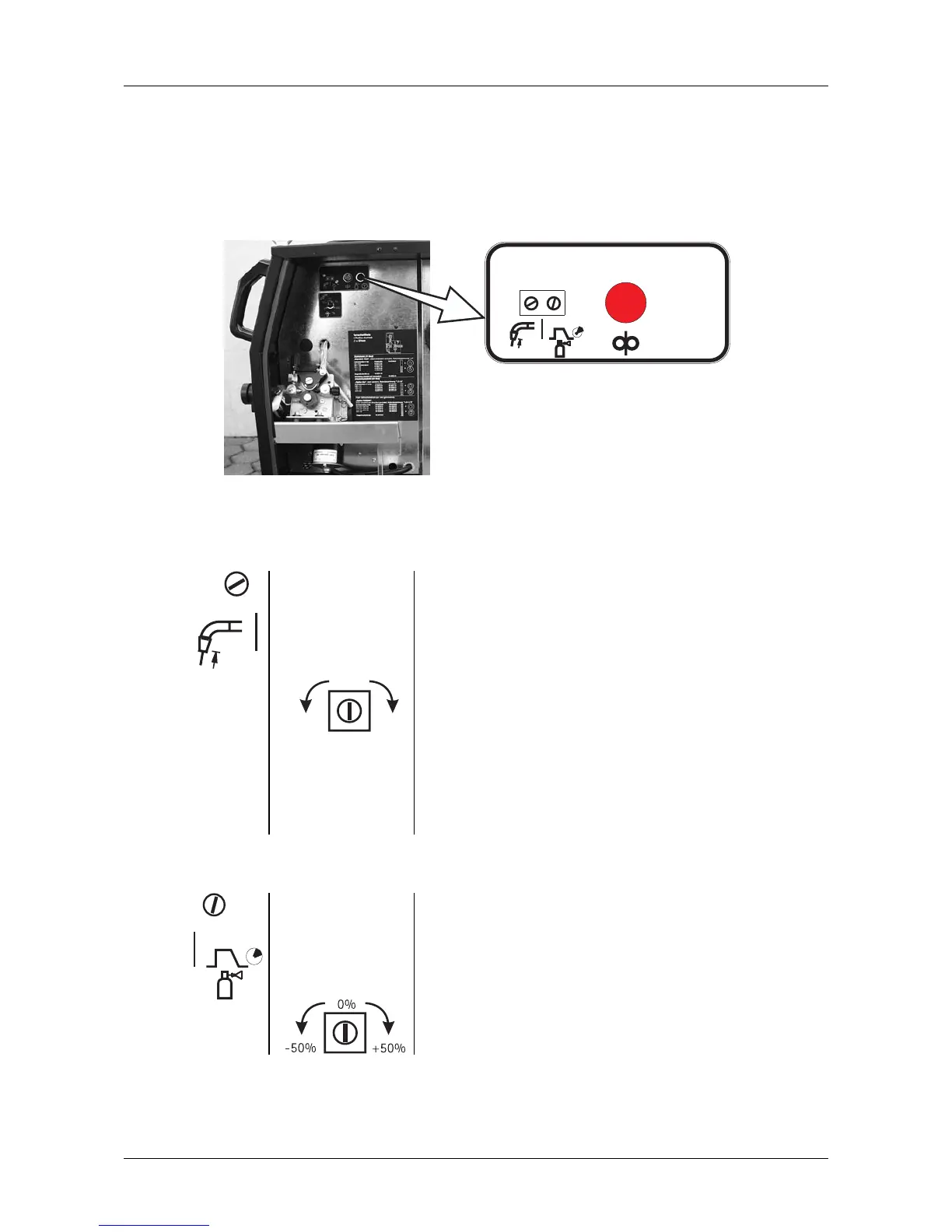

Operating elements to adjust the following welding parameters can be found in the welding

machine (Fig. 6/3), or, with the decentralised version, in the wire-feed unit.

Fig. 6/3; Adjustment possibilities in the welding machine

6.7.1 Wire Burn-back

Trimmer

Wire burn-back

time

-100% +100

0%

The time is automatically pre-set to the optimum value to

correspond with the wire-feed speed and the welding

parameters (0%), it may, however be changed by about

± 100 % with the trimmer.

Setting Instructions:

If burn-back is set too high: the formation of large globes on

the end of the welding wire causes poor arc striking

performance or the wire is melted into the contact tip.

If burn-back is set too low: the welding wire gets stuck in the

weld-pool.

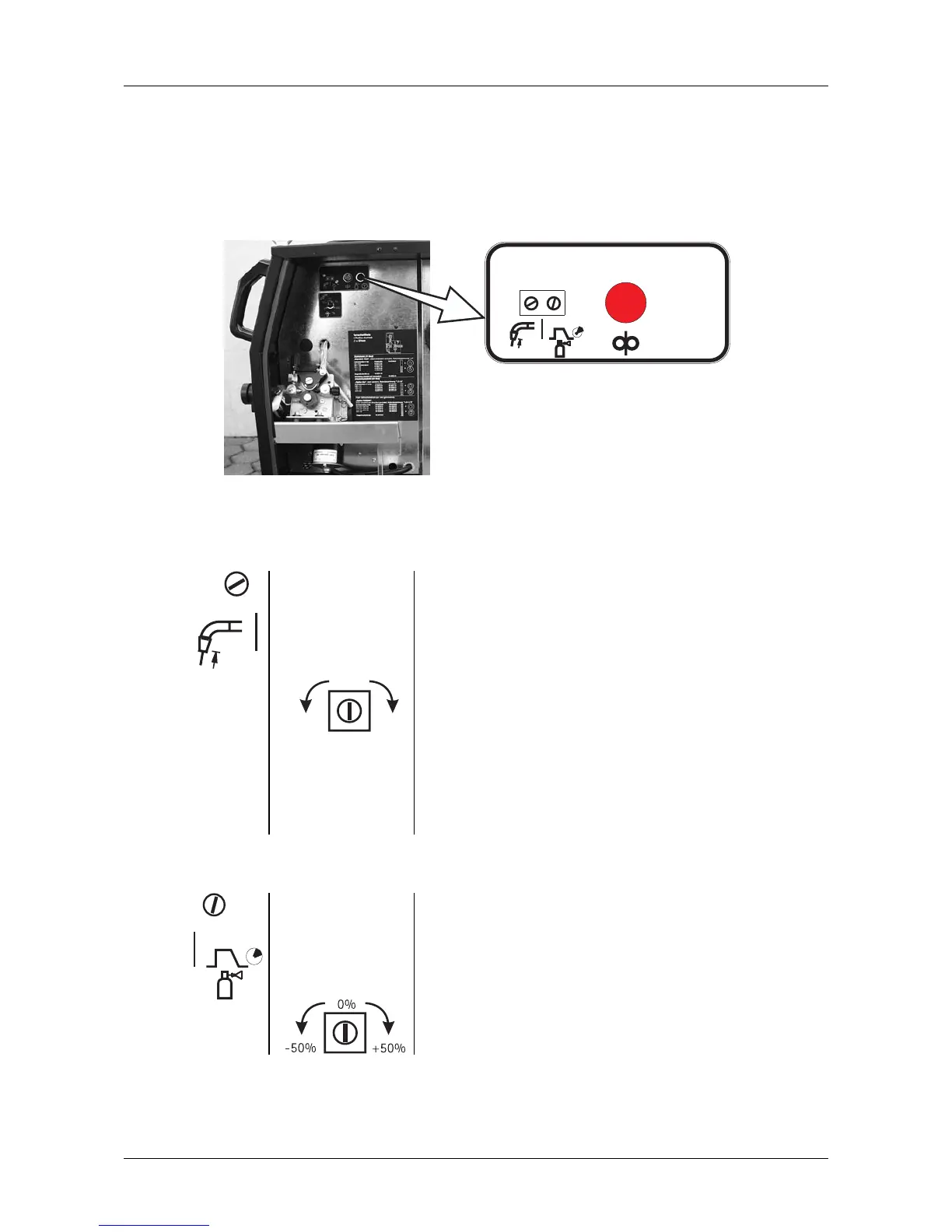

6.7.2 Gas after-flow time

Trimmer

Gas after-flow

time

The gas after flow is intended to ensure that the weld-pool

solidifies under a shielding gas atmosphere so no crater

porosity is caused. The time is automatically pre-set to the

optimum value to correspond with the material / gas

combination (0%), it may, however be changed by about

± 50 % with the trimmer.

Loading...

Loading...