8 Commissioning

8/5

8.6 Workpiece Cable

Remove paint, rust and dirt from the clamping or welding location with a wire brush! Fix the

earthing clamp or tongs close to the weld location!

Assembly aids, pipes, rails etc.. may not be used as a return lead unless theyare part of the

job itself!

A perfect current flow must be ensured on welding benches and jigs!

Torch and hosepack and the workpiece cable should never be rolled up in a spiral!

Operation whilst rolled our straight avoids voltage drops through so-called induction

losses and a negative alteration of the welding characteristics.

•

Plug the workpiece lead in one of the power sockets (choke tapping points)

"-" (Chapter 4.:

E1/F1) and lock it by turning to the right.

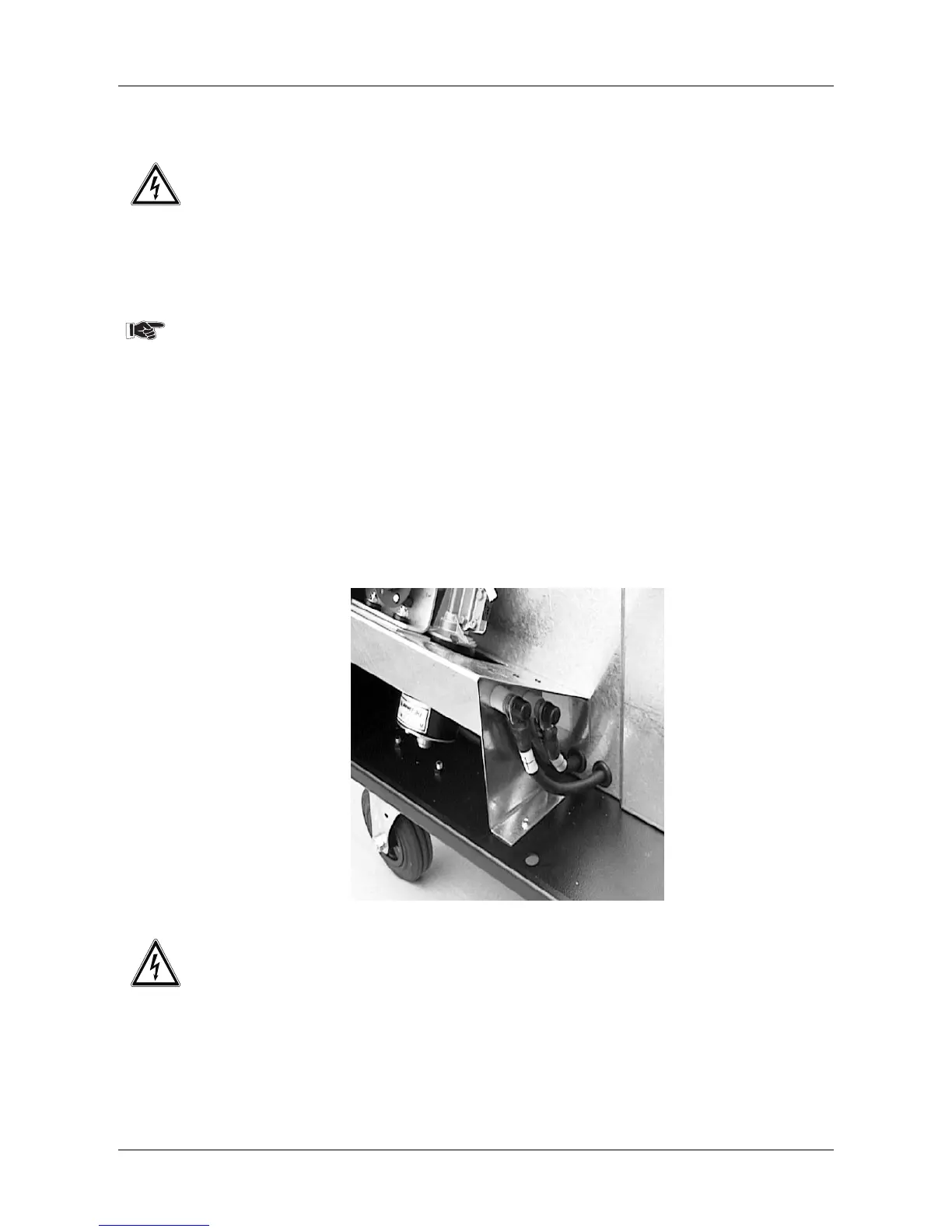

8.6.1 Changing the welding current polarity (option for cored wire welding)

The polarity of the welding current potentials (welding torch/workpiece) can be changed

inside the machine by rewiring the welding leads.

Fig. 5/3: Changing the polarity of welding current leads

Switch off the welding machine.

Withdraw the mains plug from the socket.

• Remove the plastic caps of the screw fasteners,

• unscrew the welding current leads,

• exchange the leads and screw back into place,

• replace the plastic caps.

Loading...

Loading...