Maintenance

Lubrication Chart (cont'd.)

Lubrication Char t

Fitting

Locations

Initial

Pumps

Number of

Places

Ser vice

Inter v al

1. Dec k

Idler Pi v ot

1 2

Y early

2. F ront

Caster

Pi v ots

*0

2

*Y early

g452849

Figure 23

Lubricate Caster Wheel Hubs

Service Interval : As required

1. Stop engine , w ait for all mo ving par ts to stop , and

remo v e k ey . Eng ag e parking brak e .

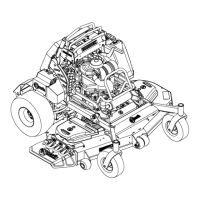

g006115

Figure 24

1. Seal guard 2. Spacer nut with wrench

ats

2. R emo v e caster wheel from caster forks .

3. R emo v e seal guards from the wheel hub .

4. R emo v e one of the spacer n uts from the axle

assembly in the caster wheel. Note that thread

loc king adhesi v e has been applied to loc k the

spacer n uts to the axle . R emo v e the axle (with the

other spacer n ut still assembled to it) from the

wheel assembly .

5. Pr y out seals , and inspect bearings for w ear or

damag e and re place if necessar y .

6. P ac k the bearings with a NLGI g rade #1

m ulti-pur pose g rease .

7. Inser t one bearing, one new seal into the wheel.

Note: Seals (Exmark P/N 103-0063) m ust be

re placed.

8. If the axle assembly has had both spacer n uts

remo v ed (or brok en loose), apply a thread loc king

adhesi v e to one spacer n ut and thread onto the

axle with the wrenc h ats facing outw ard. Do

Not thread spacer n ut all of the w a y onto the end

of the axle . Lea v e appro ximately 1/8 inc h (3 mm)

from the outer surface of the spacer n ut to the

end of the axle inside the n ut.

9. Inser t the assembled n ut and axle into the wheel

on the side of the wheel with the new seal and

bearing .

10. With the open end of the wheel facing up , ll

the area inside the wheel around the axle full of

NLGI g rade #1 m ulti-pur pose g rease .

44

Loading...

Loading...