Maintenance

Hydraulic System Air Purge

Service Interval : As required

Air m ust be purg ed from the h y draulic system

when any h y draulic components , including oil

lter , are remo v ed or any of the h y draulic lines are

disconnected.

T he critical area for purging air from the h y draulic

system is betw een the oil reser v oir and eac h

c harg e pump located on the top of eac h v ariable

displacement pump ( Figure 27 ). Air in other par ts of

the h y draulic system will be purg ed through nor mal

operation once the c harg e pump is “primed”.

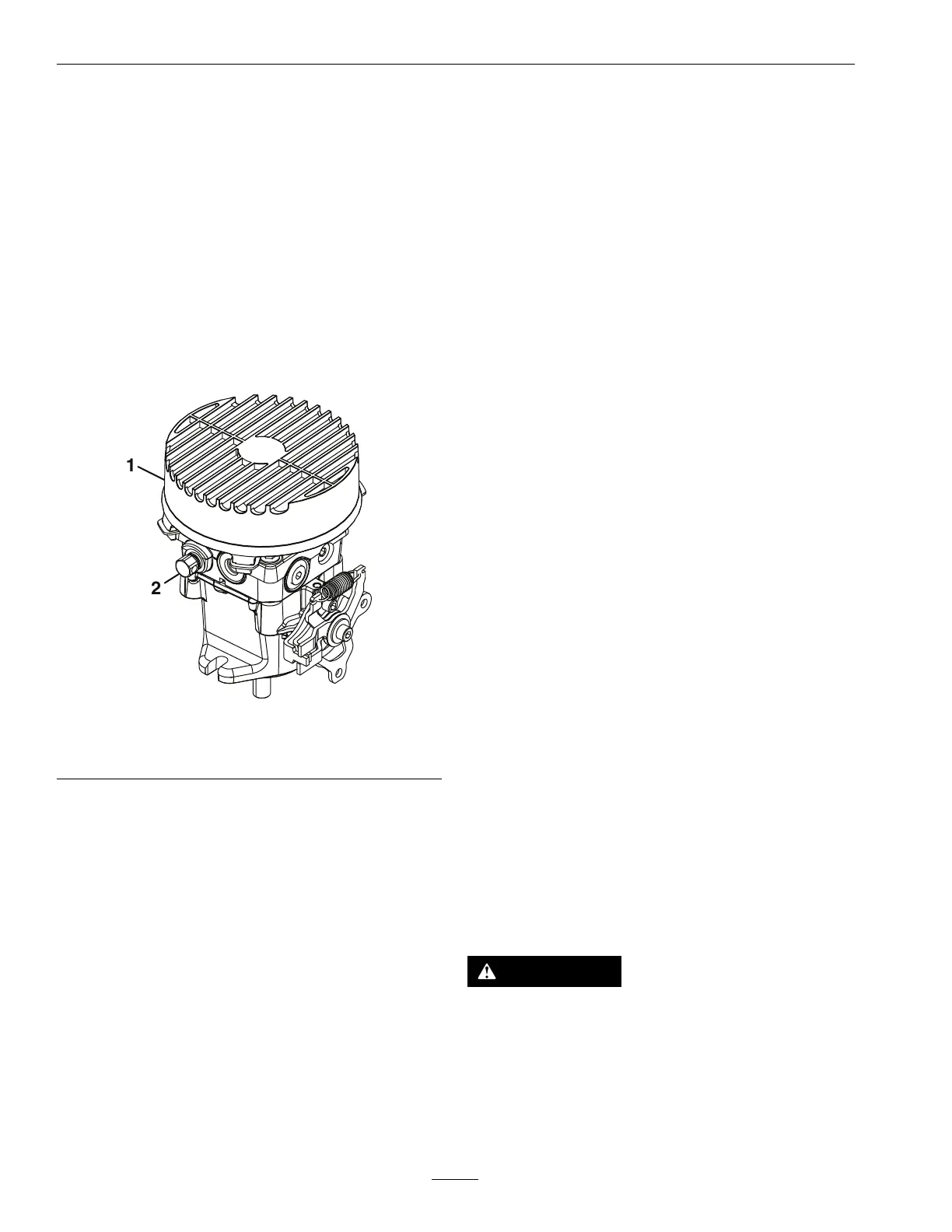

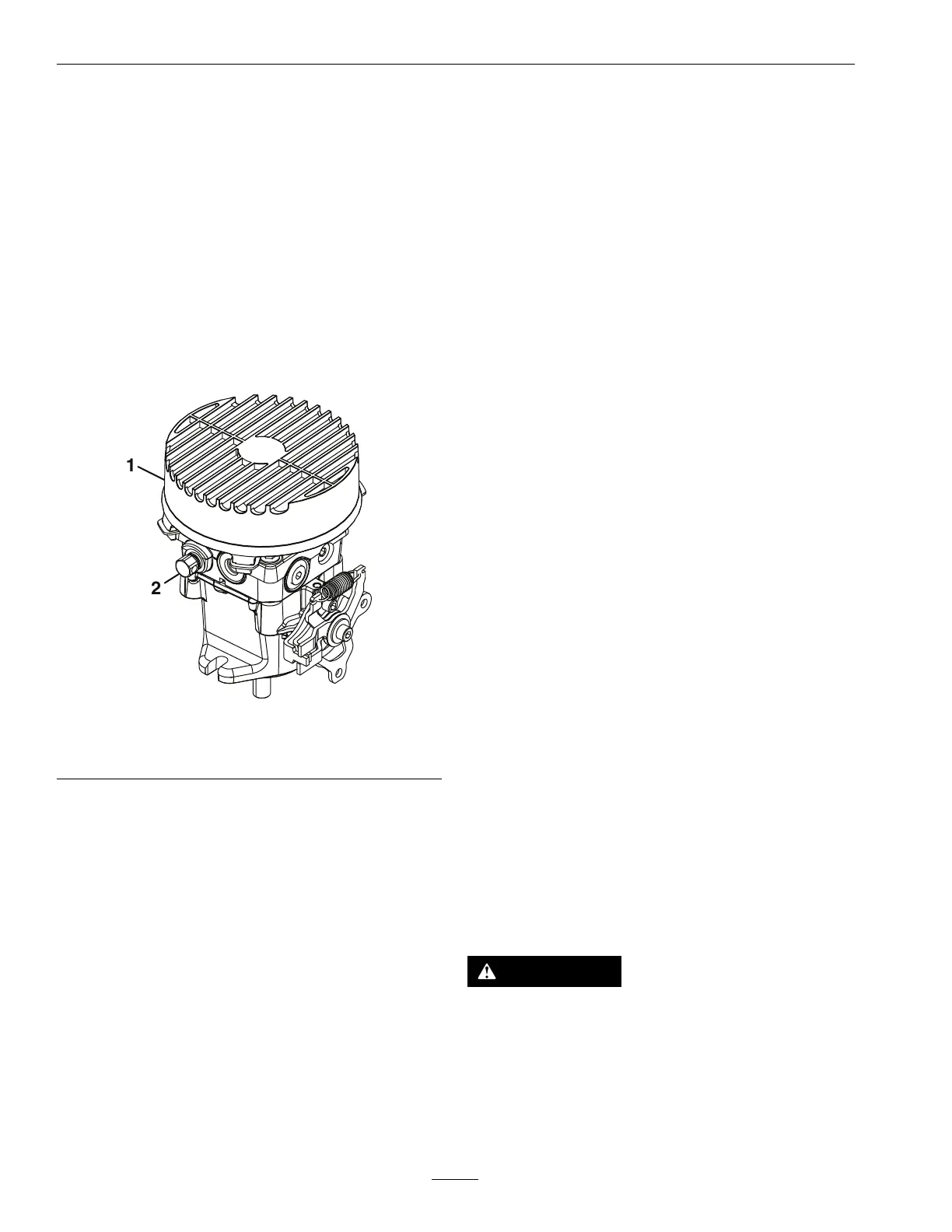

g377574

Figure 27

1. Pump fan and guard

2. Bypass valve

1. Stop engine and w ait for all mo ving par ts to stop .

Raise the rear of the mac hine up onto jac k stands

high enough to raise the dri v e wheels off the

g round.

2. Chec k oil lev el as stated in Check Hy draulic Oil

Lev el section.

3. Star t engine and mo v e throttle control ahead to

full throttle position. Diseng ag e parking brak e

and mo v e motion control lev ers forw ard with

equal pressure .

If either dri v e wheel does not rotate , it is possible

to assist the purging of the c harg e pump b y

carefully rotating the tire in the forw ard position.

Note: It is necessar y to lightly touc h the pump to

c hec k the pump temperature . If the pump is too

hot to touc h, tur n off engine . T he pumps ma y be

damag ed if the pump becomes too hot.

If either dri v e wheel still does not rotate contin ue

with ste p 4 .

4. Open the b ypass v alv e (sho wn in Figure 27 ).

5. With the b ypass v alv e open and the engine

r unning, slo wly mo v e the motion control lev ers

in both forw ard and rev erse directions v e to six

times . As air is purg ed from the unit, the oil lev el

in the reser v oir will drop .

6. Close the b ypass v alv e . With the b ypass v alv e

closed and the engine r unning, slo wly mo v e the

motion control lev ers in both forw ard and rev erse

directions v e to six times .

7. Allo w unit to r un sev eral min utes after the c harg e

pumps are “primed” with dri v e system in the full

speed position. Chec k oil lev el as stated in Check

the Hy draulic Oil Lev el section.

8. Chec k h y dro dri v e linkag e adjustment as stated in

Hy dr o Dri v e Linka ge Adjustment section in

Adjustments .

Wheel Hub Nut

Specication–S-Series

Only

Service Interval : After the rst 100 hours

Every 500 hours thereafter

T or que the n ut on the wheel motor tapered shaft to

211-260 ft-lb (286-352 N-m).

Note: Do Not use anti-seize compound on the

wheel hub .

Check Spark Arrester

(if equipped)

Service Interval : Every 50 hours

W ARNING

Hot exhaust system components may ignite

gasoline v apor s ev en after the engine is stopped.

Hot par ticles exhausted during engine operation

may ignite amma ble materials. Fir e may r esult

in per sonal injur y or pr oper ty dama ge.

Do Not r efuel or r un engine unless spar k ar r ester

is installed.

48

Loading...

Loading...