Maintenance

11. Inser t the second bearing and new seal into the

wheel.

12. Apply a thread loc king adhesi v e to the 2nd spacer

n ut and thread onto the axle with the wrenc h ats

facing outw ard.

13. T or que the n ut to 75-80 in-lb (8-9 N-m), loosen,

then re-tor que to 20-25 in-lb (2-3 N-m). Mak e

sure axle does not extend bey ond either n ut.

14. R einstall the seal guards o v er the wheel hub and

inser t wheel into caster fork. R einstall caster bolt

and tighten n ut fully .

Important: T o pr ev ent seal and bearing dama ge,

check the bearing adjustment often. Spin the

caster tir e. T he tir e should not spin fr eel y

(mor e than 1 or 2 r ev olutions) or ha v e an y side

play . If the wheel spins fr eel y , adjust torque on

spacer n ut until ther e is a slight amount of dra g .

R eappl y thr ead locking adhesi v e.

Check Spark Plugs

Service Interval : Every 200 hours

R emo v e spark plugs , c hec k condition and reset g aps ,

or re place with new plugs . See Engine Owner's

Man ual.

Change Fuel Filter

Service Interval : As required

A fuel lter is installed betw een the fuel tank and the

engine . R e place when necessar y .

Note: It is impor tant to reinstall the fuel line hoses

and secure with plastic ties the same as they w ere

originally installed at the factor y to k ee p the fuel line

a w a y from components that could cause fuel line

damag e .

Change Hydraulic System

Filter and Fluid (X-Series)

Service Interval : After the rst 250 hours

Every 500 hours/Y early

(whichever comes

rst) thereafter .

(Every 250 hours/Y early

if using Mobil 1 15W50

thereafter)

Note: Use only Exmark P ar t No . 109-4180 for

Summer use abo v e 32°F (0°C) or P/N 1-523541 for

Winter use belo w 32°F (0°C) (R efer to T ransmission

section in Specications for lter specications).

1. Stop engine , w ait for all mo ving par ts to stop , and

remo v e k ey or spark plug wire(s). Eng ag e parking

brak e .

2. R emo v e and retain the thigh pad and rear guard.

3. Raise the rear of mac hine up and suppor t with

jac k stands (or equi v alent suppor t) just high

enough to allo w dri v e wheels to tur n freely .

CAUTION

R aising the mo w er f or ser vice or maintenance

r el ying solel y on mechanical or h y draulic

jacks could be danger ous. T he mechanical or

h y draulic jacks may not be enough suppor t

or may malfunction allo wing the unit to f all,

which could cause injur y .

Do Not r el y solel y on mechanical or h y draulic

jacks f or suppor t. Use adequate jack stands

or equi v alent suppor t.

4. R emo v e and retain right and left dri v e tires and

lug n uts .

5. Use a catc h pan when draining the h y dro oil.

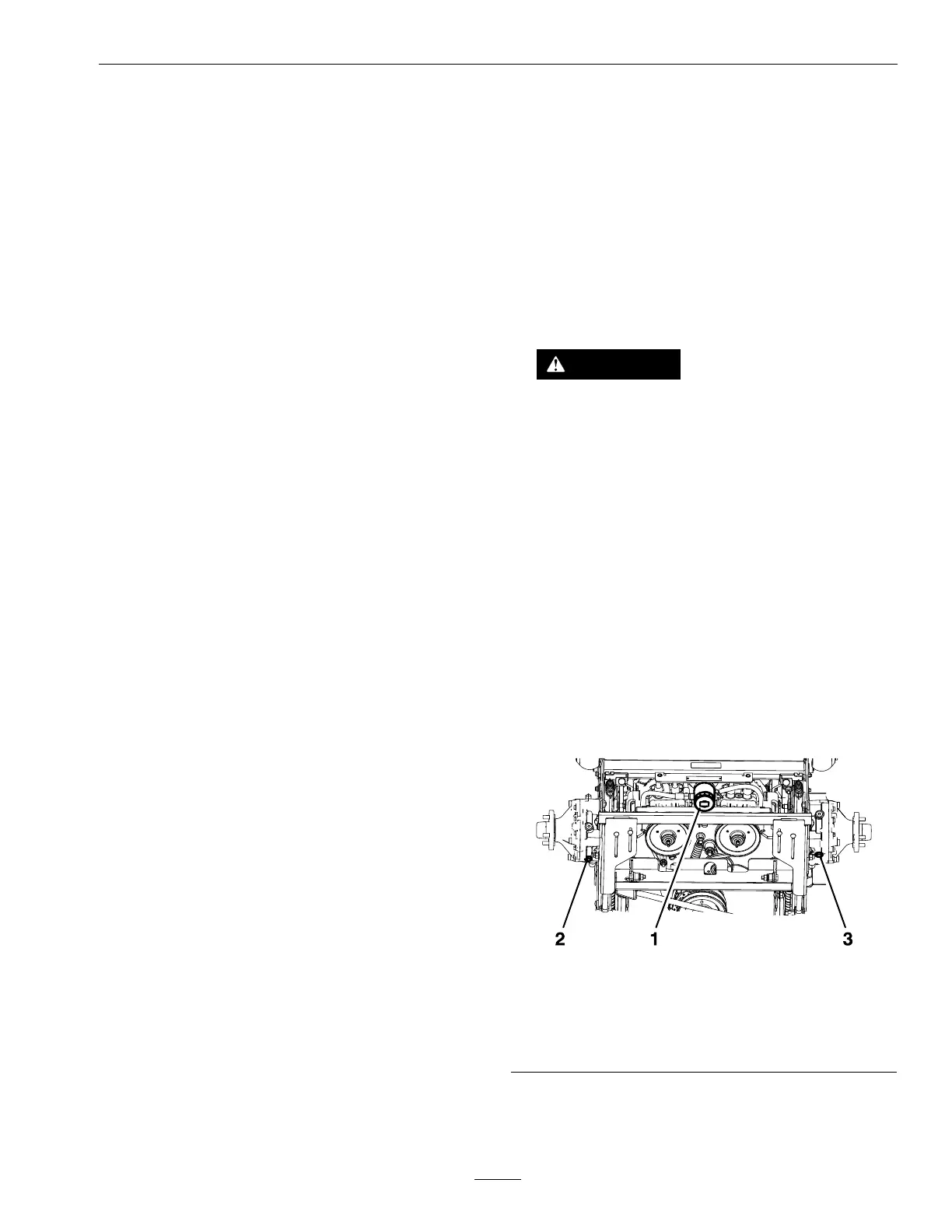

6. T here are three drains that need to be remo v ed to

do a complete uid c hang e . Place a pan under

eac h drain from the follo wing components:

h y draulic lter and the left and right wheel motors .

g451535

Figure 25

Some components removed for clarity

1. Hydraulic lter

3. Right wheel motor plug

2. Left wheel motor plug

7. Carefully clean area around lter . It is impor tant

that no dir t or contamination enter h y draulic

system.

45

Loading...

Loading...