FARO Gage

May 2011

40

Chapter 6: Maintenance and Troubleshooting

• Make sure the Gage probe is secure. Only hand-tighten the probe with the

12mm wrench. Do not over-tighten the probe.

• Make sure that the compensation hole, cone or sphere is located about 2/3

the distance of the Gage from the base.

• Make sure that the compensation cone, or sphere, is securely screwed into

the holder and that the holder is securely fastened to a stable surface.

• Make sure that probe tip is in contact with hole, cone or sphere.

• Compensate the probe again, and check that all points were digitized

properly.

• Use the other compensation method (sphere or hole).

Buttons (FRONT & BACK) will not respond.

• Make sure that all of the encoders are referenced. See “Referencing the

Encoders” on page 17.

• Turn auxiliary port OFF. See “Edit Probe” on page 55.

• Check buttons in Diagnostic command. See “Diagnostics” on page 65.

Single-point calibration shows excessive error.

• You must use a ball probe. Check that it is installed correctly. See “Installing

Probes” on page 11.

• Recompensate probe. See “Compensate Probe” on page 56.

• During the test, watch the probe to ensure flush seating in the hole. See

“Gage Calibration” on page 32.

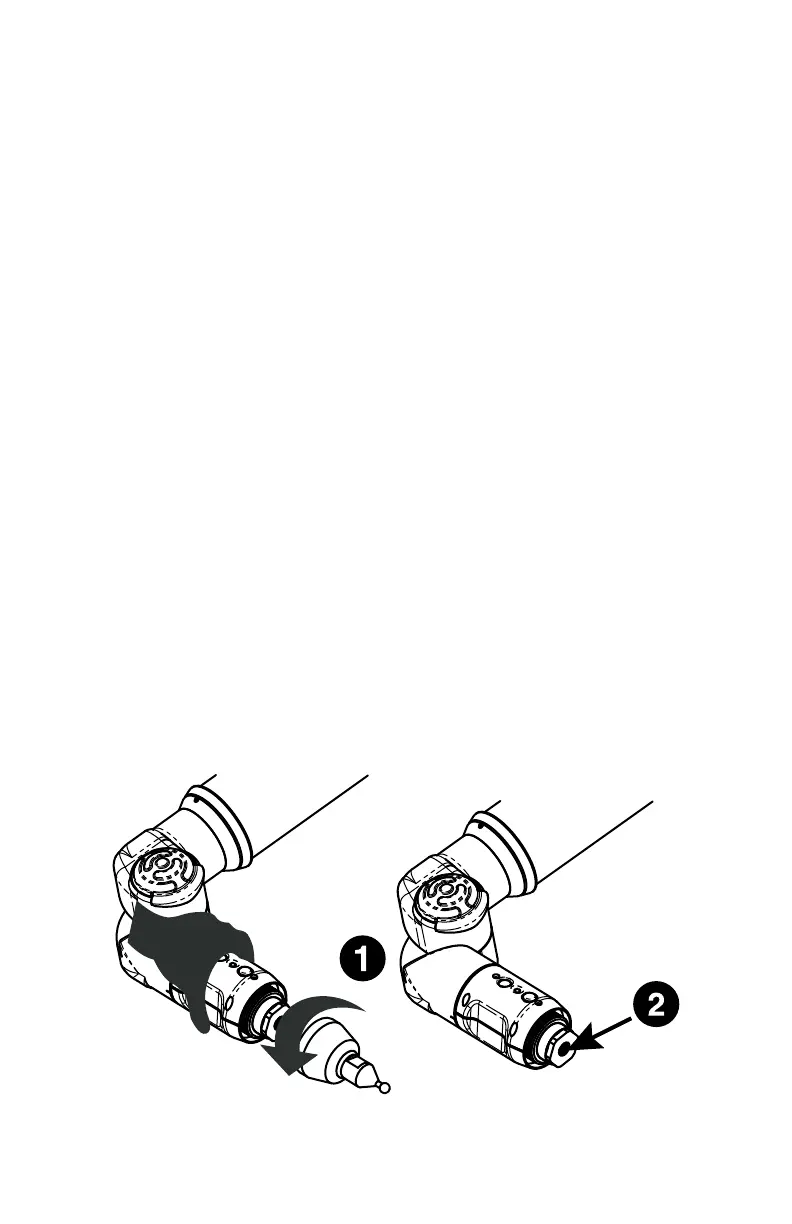

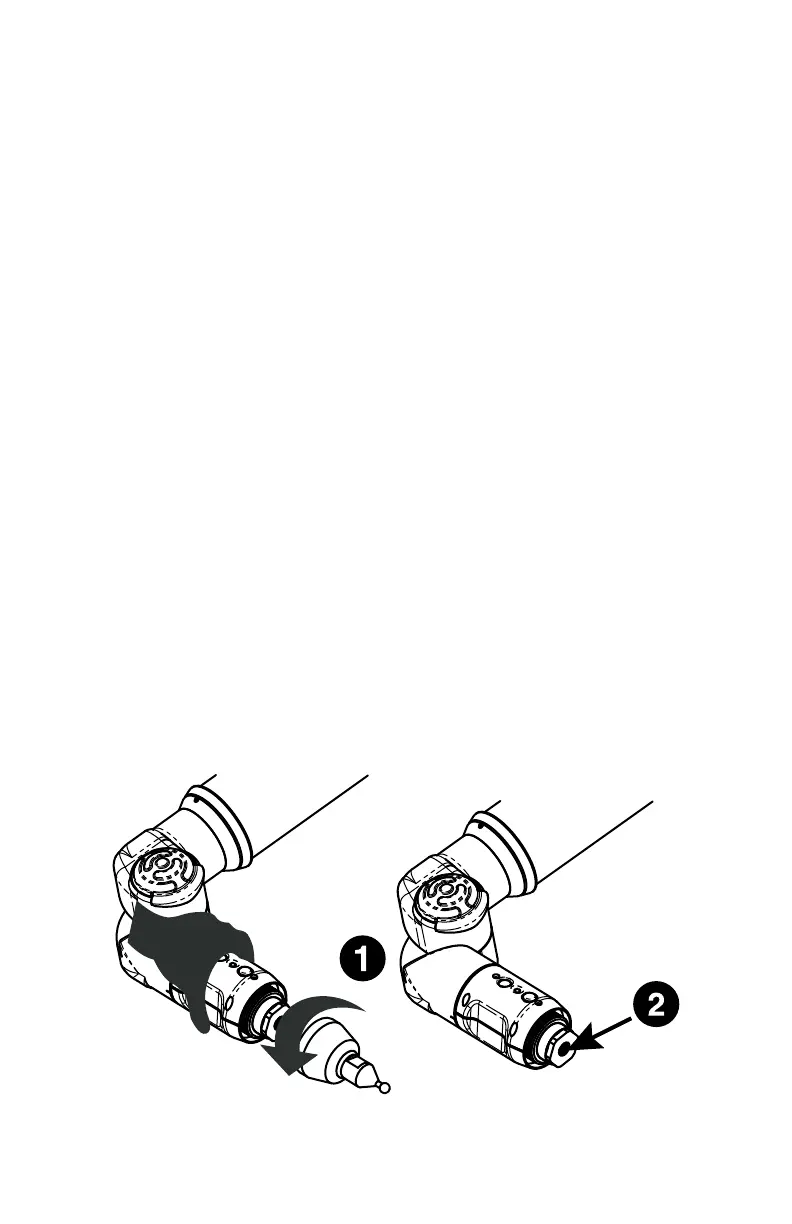

Gage records points without pressing either button.

• Re-seat the set screw in the Gage handle. If the set screw is not seated

correctly it causes intermittent contact to the pin underneath, and random

points are taken.

Figure 6-1 Handle Screw

08M47E00_FAROGage.book Page 40 Wednesday, June 8, 2011 4:12 PM

Loading...

Loading...