FARO Gage

May 2011

56

Chapter 7: Configuring the FARO Gage in CAM2 Gage

are translated into Gage coordinates and you are ready to start taking

measurements.

Measurement accuracy relies on probe compensation under optimal conditions.

If the probe compensation passes, measurements will be accurate. If the probe

compensation fails, measurements will not be as accurate. Proper mounting and

technique are critical compensation factors.

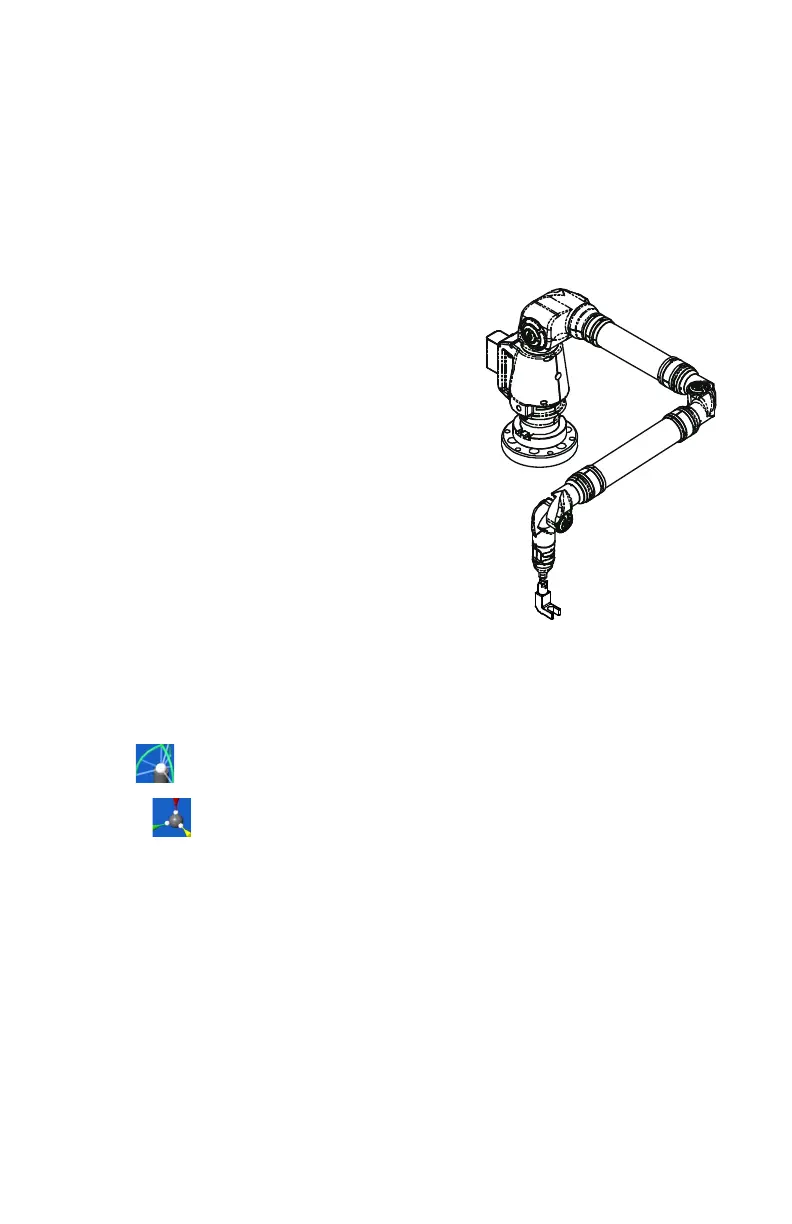

To optimize compensation and minimize stress-

induced errors during this critical procedure,

place the Gage in a single position in which the

elbow joint remains relatively stationary without

any obstructions or restrictions in movement

while the compensation is performed. Do not let

the elbow joint fall during compensation. Only

exercise the last joint of the Gage for the software

to accurately compensate the probe tip.

Minimizing elbow joint movement and focusing

on the probe and last arm joint during

compensation maximizes measurement accuracy.

Compensate Probe

When changing the style or dimension of the probe at the end of the Gage, you

must compensate it for the Gage to measure and function accurately. Probe

compensation is an optimization procedure that requires you to digitize points.

The two methods of compensation are:

•Hole

• Sphere

Click either button to compensate the current probe. The Hole Compensation

method differs depending on whether the G

UIDANCE check box is selected or

cleared. See “Edit Probe” on page 55.

• See “Hole Method - Guidance” on page 57.

• See “Hole Method” on page 60.

• See “Sphere Method” on page 62.

08M47E00_FAROGage.book Page 56 Wednesday, June 8, 2011 4:12 PM

Loading...

Loading...