EXTENDED MODE

CARD G / FIT 68 V 6.15 E / April 2010

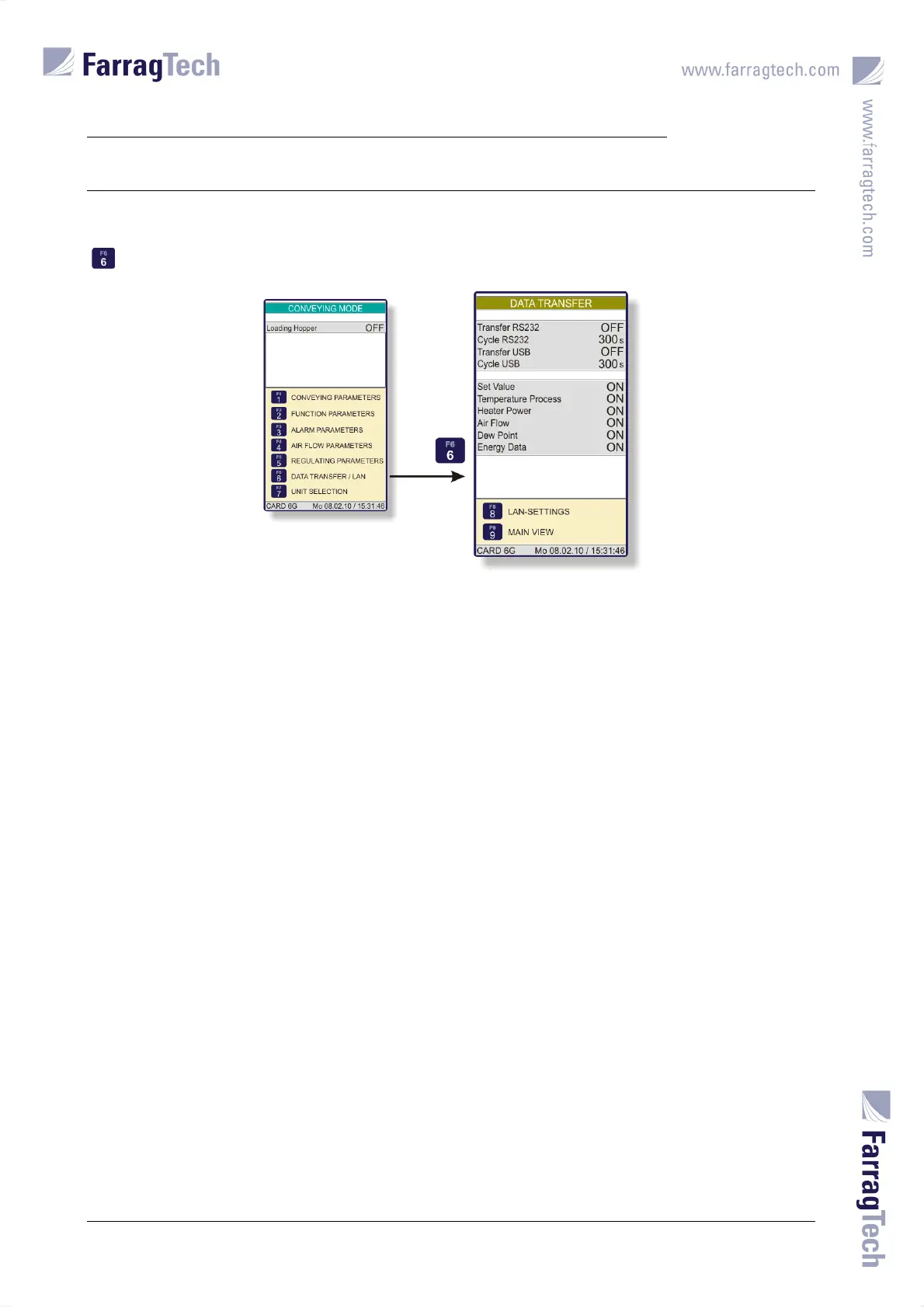

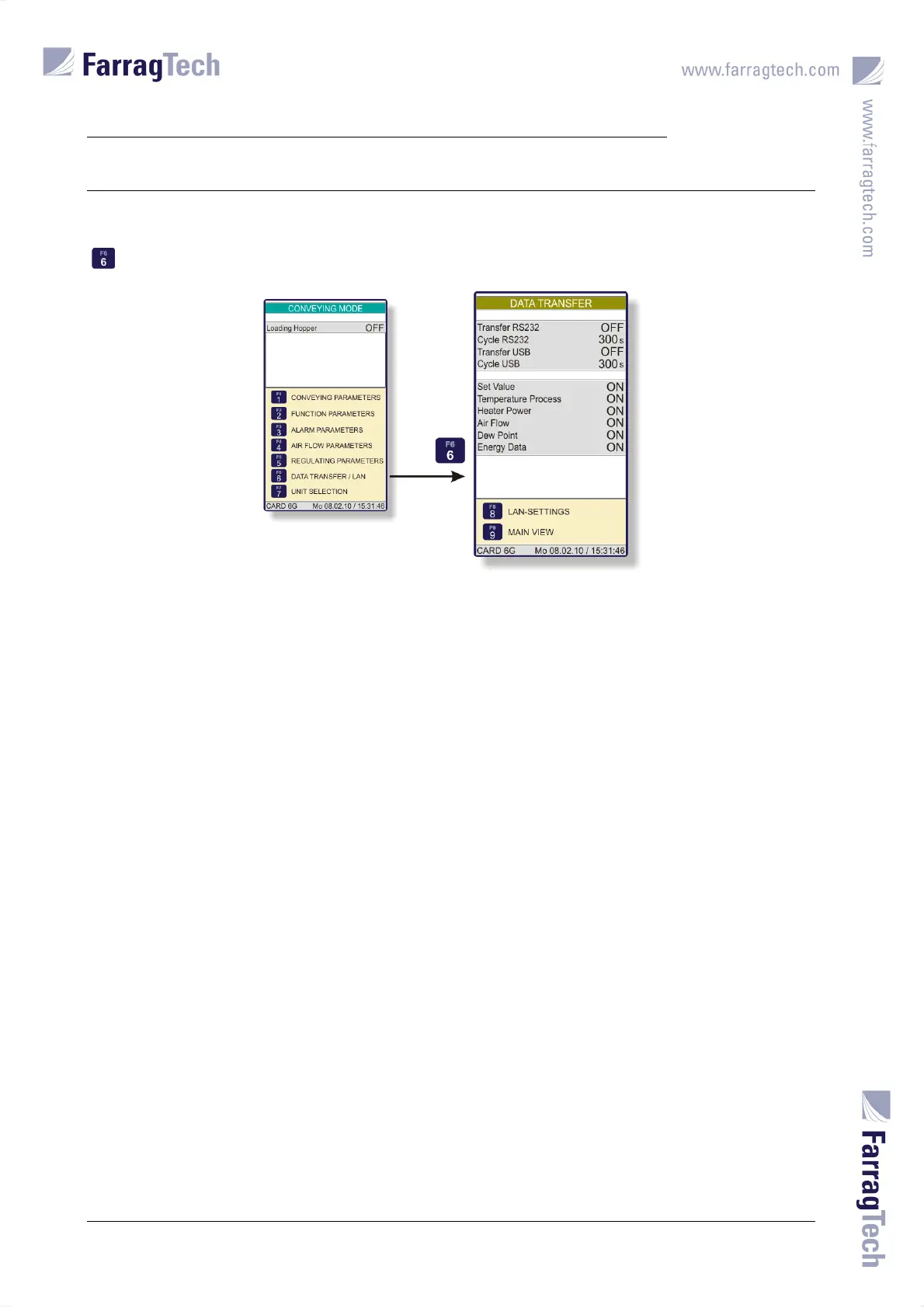

17.10.1 DATA TRANSFER

The parameters for DATA TRANSFER are attained from the screen CONVEYING MODE with the key

.

Process data of the CARD G FIT can be recorded through the serial port or through a USB-stick

plugged into the FIT-controller.

Data logging through the serial port is barely used anymore but still offered to keep the

compatibility to the former model of the FIT-controller. Detailed information can be found in the

SYSTEMS MANUAL CARD G FIT if this type of logging still wants to be used.

Data recording through a USB-stick is a simple and efficient way to document the drying

process. This method requires a USB-stick plugged into the FIT-controller inside of the

CARD G FIT.

A record is made every 300 seconds (5 minutes). This time can be changed by the operator but it

is recommended to retain this value, so that the amount of data is kept within an acceptable

range. A USB-stick with a memory size of 2 Gigabytes will be able to store process data up to 50

years using the pre-set time interval.

A new file with data is automatically created every day. The file name is build from the date of

recording. 288 data records will be written to such a file per day if the time interval is set to 300

seconds. This prevents a file becoming too big which simplifies the data evaluation and

minimizes the risk of data loss in case of a corrupted file.

Data are saved in a comma separated value (csv)-file and can easily be imported and analyzed in

various programs (e.g. Microsoft Excel, Lotus etc.).

Fault and event messages are saved in a text file.

Following parameters are available in this menu:

Loading...

Loading...