A. Technical appendix

A-3

Festo P.BE-CB-COMP-EN en 1102d

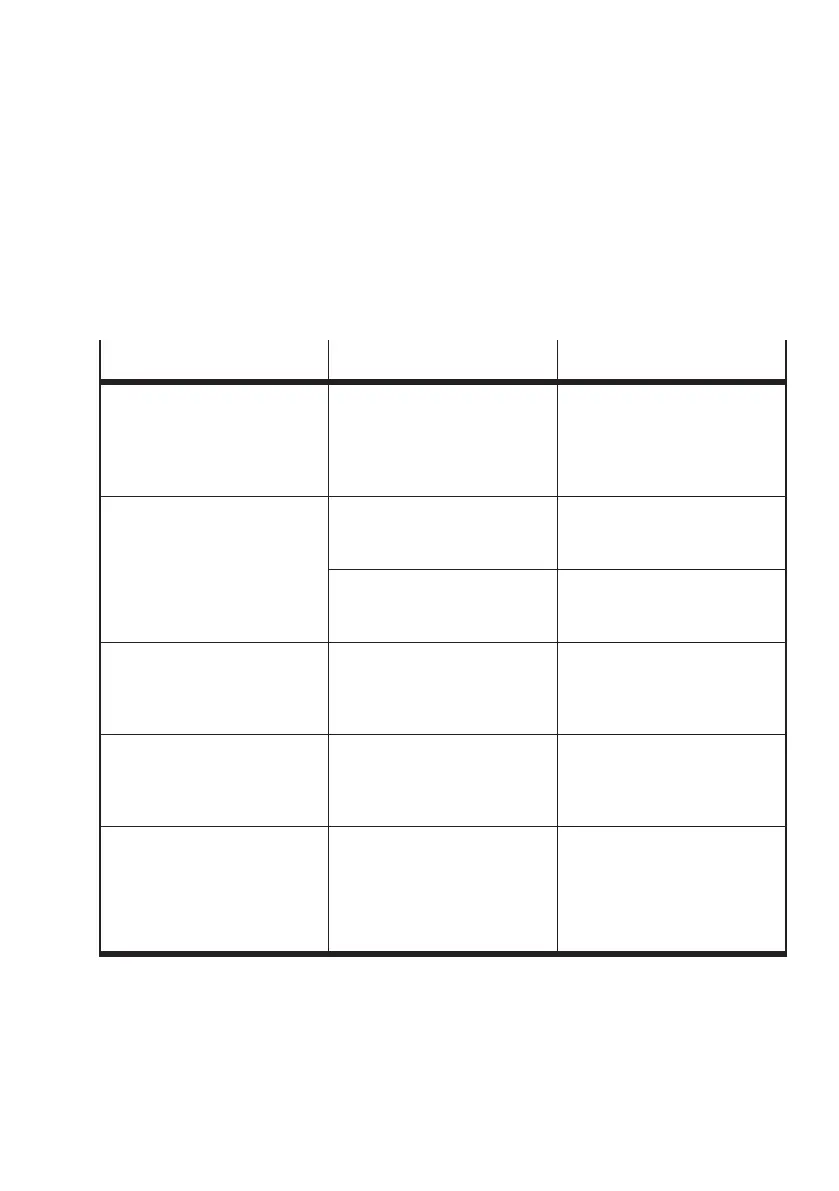

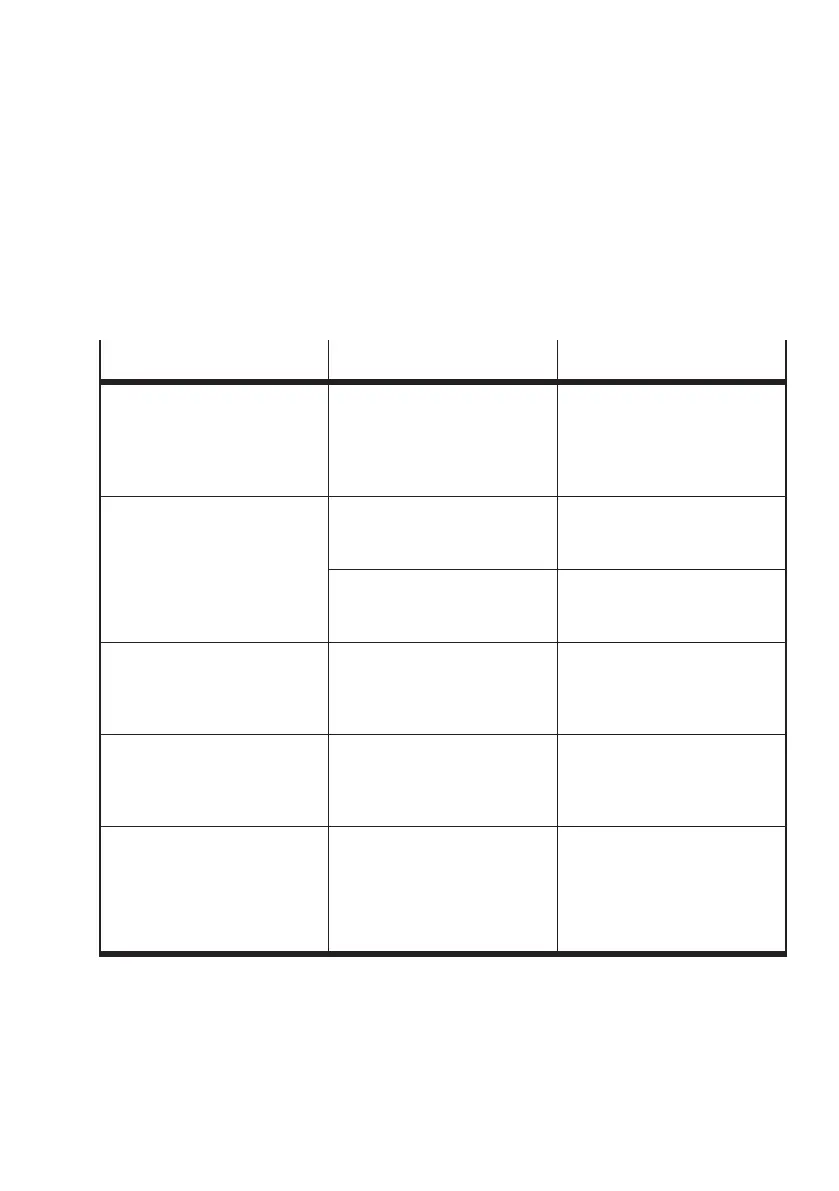

A.1 Operating malfunctions

A.1.1 General fault finding

Problem Cause Action

Device does not function, both

illuminated push-buttons are

flashing.

Ambient, setting, data or

hardware fault

1. Identify fault coding in

Appendix A.1.2.

2. Eliminate fault.

3. Acknowledge with

START/STOP button.

Good inspection par t s are

sorted as bad parts.

– Tolerance set too low – Increase toleranc e and

repeat Teach procedure with

more sample parts.

– Incorrect parts type selected

by external type preselection

at the PLC connection.

– Select the (correct) parts

type with external type

preselect.

Bad inspection parts are

accepted as good parts by the

device.

– Tolerance is set too high.

–Deviationsarenot

recognisable for the

Checkbox.

– Reduce tolerance.

– With CheckOpti: Optimize the

Teach data.

– Display cFul

– Good part s are blown back

into the small parts c onveyor

in all orientations.

The preselected counter status

is reached and is not reset by

the external controller.

– Check connection to

controller.

–CheckPLCprograminthe

controller.

–Responsetime

point/duration of the

Checkbox is not correct.

– Inspection part deviation is

shown fo r an unusually long

time.

Checkbox runs in the diagnostic

mode.

– With CheckKon: switch from

the diagnostic mode to t he

operating mode, or

– Conclude

CheckKon/CheckOpti.

Tab. A/1: Faults and remedies

Loading...

Loading...