2. Fitting and commissioning

2-7

Festo P.BE-CB-COMP-EN en 1102d

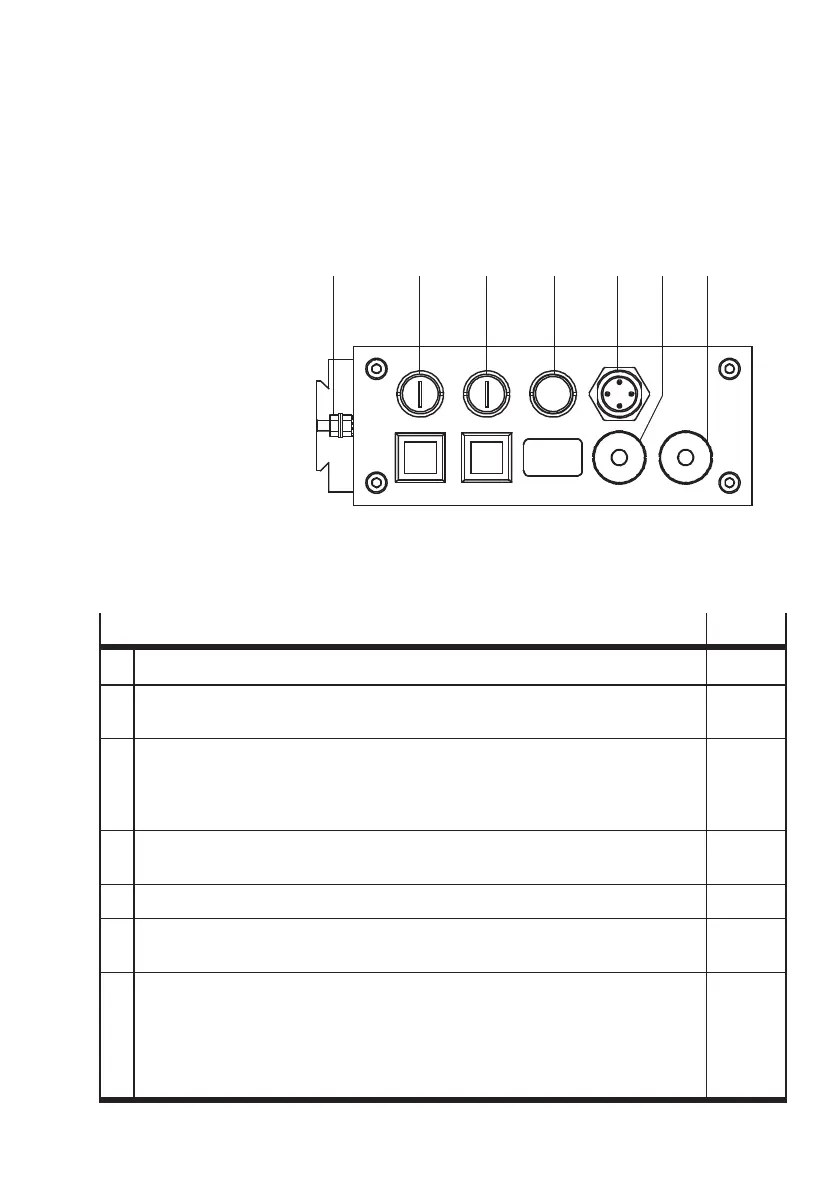

2.3 Electrical connection

1

FE

2 ACTUA TORS

3 BUFFER/FEEDER

4 DIAG

5 24 V DC

6 ENCODER

7 PLC

1234567

Fig. 2/4: Connections of the Checkbox

Function

Chapter

1 – Functional ear th connection 2.3

2 – Connection of a maximum of 3 actuators for sor t ing out the tested conveyed

parts

3.2

3 – Connection of 1 buffer zone sensor for controlling the transfer of work items to

the next machine

– 24 V po wer out puts fo r controlling the supply system (small parts conveyor) and

the transpor t ing system (conveyor device)

3.3

4 – Connection of a diagnostic PC for system diagnosis, visualizing and optimizing

the test procedure with the software packages CheckKon and CheckOpti

3.4

5 – Connection of the 24 V DC power supply 2.3

6 – Connection of a rotary pulse generator for determining the speed of the conveyor

system with increased demands for length ac c uracy

3.5

7 – Connection of 2 buffer zone sensors for controlling the transfer of work items to

the next machine

– 24 V po wer out put f or controlling the supply system (small parts conveyor) and

the transpor t ing system (conveyor device)

– I/O signals for process monitoring and higher-order control or for controlling a

downstream-switched machine.

3.6

Loading...

Loading...