4. Teaching parts

4-10

Festo P.BE-CB-COMP-EN en 1102d

4.2.2 Observing the scatter of characteristics

C...

Observethedisplaywhenscanningthesampleparts.It

shows briefly for each part the maximum value of the scatter

of characteristics for the current feature which differs to the

greatest extent (C-value).

The following factors influence the scatter of characteristics:

– parts geometry

– different contours of the part, depending on the swivel

angle around the longitudinal axis (e.g. with springs,

screws)

– different positioning on the conveyor device.

If the displayed C-value changes erratically, you have prob-

ably placed the conveyed part incorrectly on the conveyor

device. If the C-value changes only minimally, a sufficient

scatter of characteristics in the current orientation has prob-

ably been achieved. The optimum situation is when the curve

of the values changes at first considerably and then becomes

increasingly more constant.

Small values indicate narrow manufacturing tolerances and a

steady supply of par ts. Very large values indicate that the

taught sample parts differ greatly from each other with

regard to their properties. If the (good) parts are allowed to

differ greatly from each other, the Teach procedure can

nevertheless still be continued.

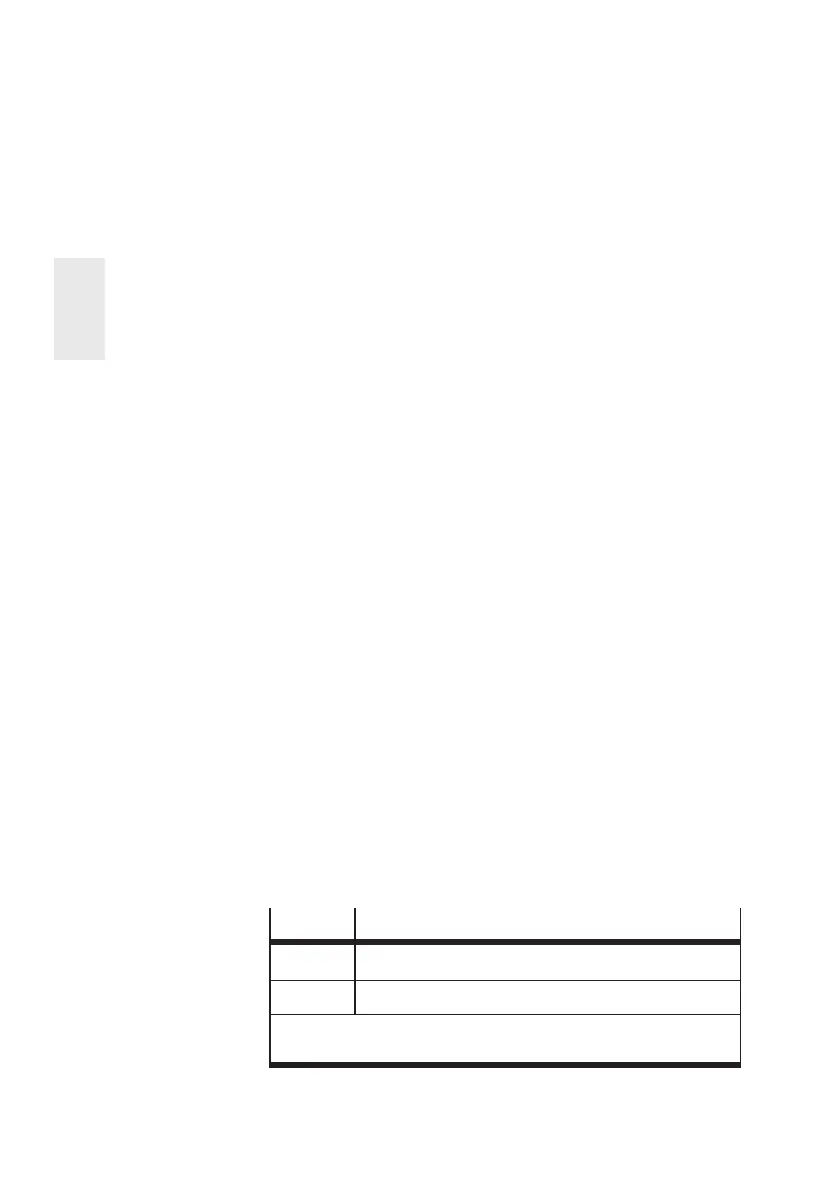

C-value

Significance

. 10 Sample parts are very similar in all features

, 30 Large scatter of at least one feature

An exact description of the calculation algorithm for the scatter of

characteristic s can be found in Appe ndix A.3.2.

Tab. 4/1: C-value (scatter of characteristics)

Loading...

Loading...