Contents and general instructions

XIV

Festo P.BE-CB-COMP-EN en 1102d

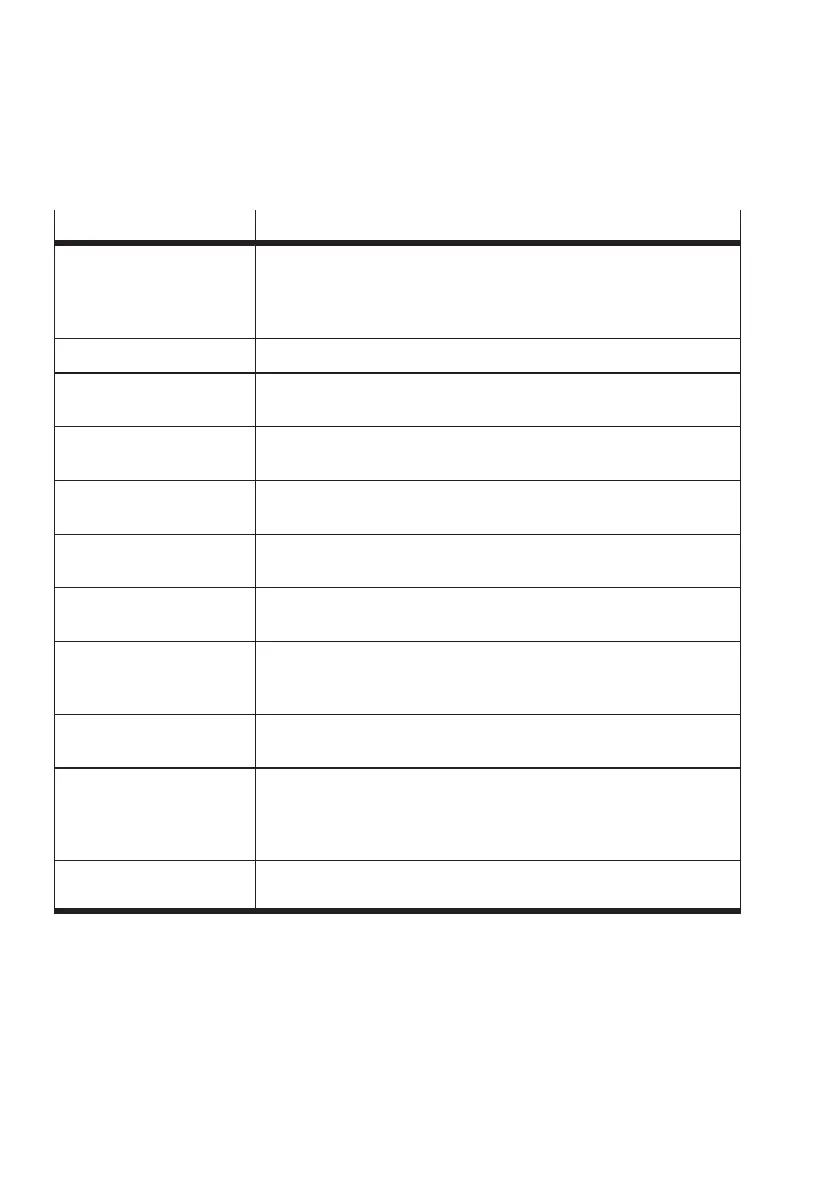

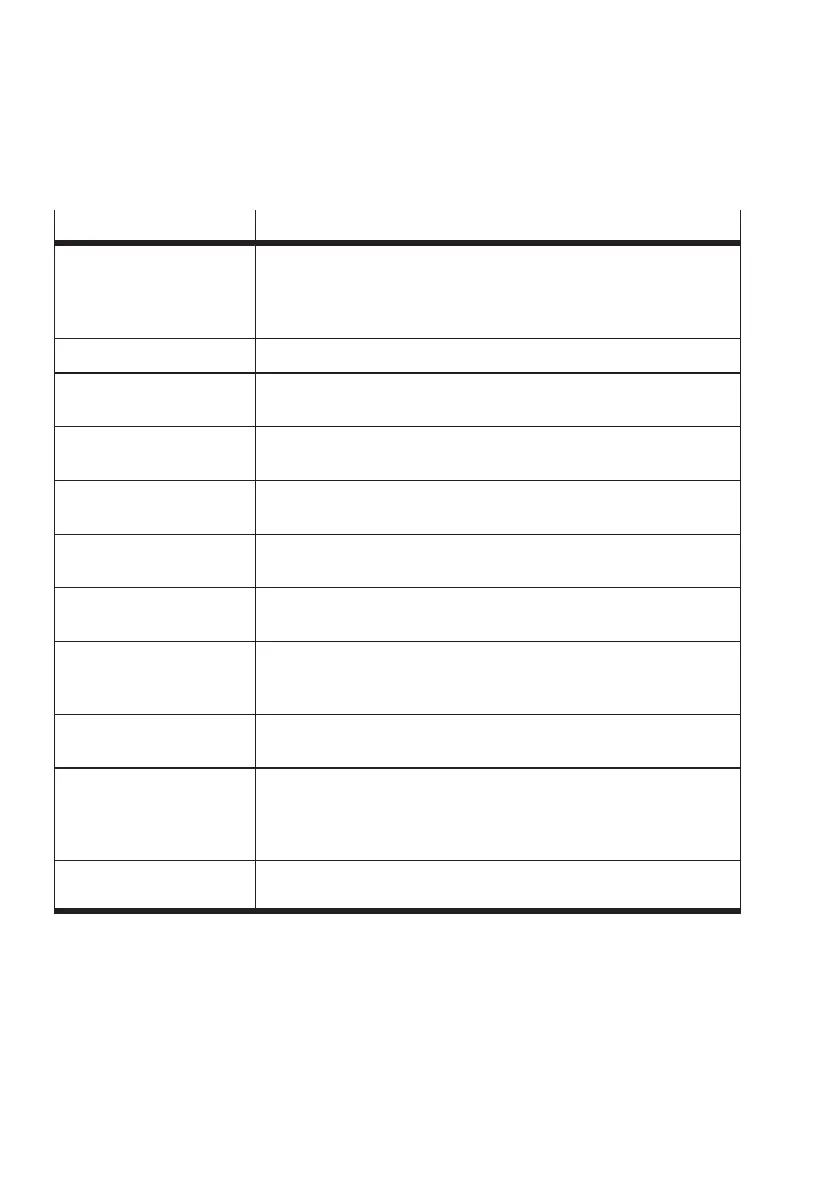

Term/abbreviation Significance

Orientation The parts to be tested by the Checkbox can be placed on the conveyor

belt facing in different directions. During the Teach procedure you can

define the orientations by showing the different directions. Orientation

1 is the preferred orientation (nominal orientation)

Parts type Conveyed part defined by the Teac h data of the sample parts.

Reject part An inspection part on which at least one feature lies outside the

tolerance.

Sample parts Good parts which have been selected for the Teach procedure and

which possess all the features necessary for identifying the parts type.

(System) parameters Settings of t he Checkbox (in some cases can only be set with

configuration software)

Teach data All features ascer t ained during the Teac h procedure, eac h with

min./max. limits and the average value.

TEACH mode Operating mode of the Checkbox in which the Teach procedure is

carried out.

Teach procedure During the Teach procedure, sample parts on the conveyor belt are

shown to the Checkbox and the features are scanned. This is also

referred to as “Teaching pa rt s”.

Test dat a Thetestdataarethedatausedforthetest.Thesecorrespondtothe

Teach data plus admitted tolerances.

Test procedure During the t est procedure, inspection par ts on the conveyor belt are

shown to t he Checkbox and graded ac c ording to their features with

regard to orientation and observance of the tolerances. This is also

referred to as “Testing parts”.

Toleranc e Fact or in per cent related to the average values and which affects the

min./max. limits of all features.

Tab. 0/2: Terms and abbreviations

Loading...

Loading...