3. The I/O module

3-16

Festo P.BE-CB-COMP-EN en 1102d

Special functions of the PLC interface

1)

Pin

Error messages Fault status 0: Warning O/23

Monitoring the buffer zones and controlling the parts

supply with switch hysteresis

Buffer zone sensor 2

2)

I/13

Additional test of material features which are not chec ked

during contour registering (e.g. by metal detector or

colour sensor). Downstream-switched test function,

e.g. only good par t s are checked.

External sensor

3) 4)

I/10

Externally controlled switching on/off of the picture

registration under particularly difficult conditions.

Camera trigger I/9

Such as for monitoring the pneumatic supply fo r th e

actuators: In the event of a fault, the CHB-C-X will be

switched to fault status E 01 by means of a pressure

switch.

External fault I/19

1)

Deactivated at t he factory Functions can be activated and adapted with CheckKon.

2)

Can be set optionally with CheckKon, set at factory “External type selection: bit 2”.

3)

Counter function and special function “External sensor” cannot be use d at the same time.

4)

Can be set optionally with CheckKon, set at factory “External type selection: bit 3”.

Tab. 3/5: Special functions of the PLC interface

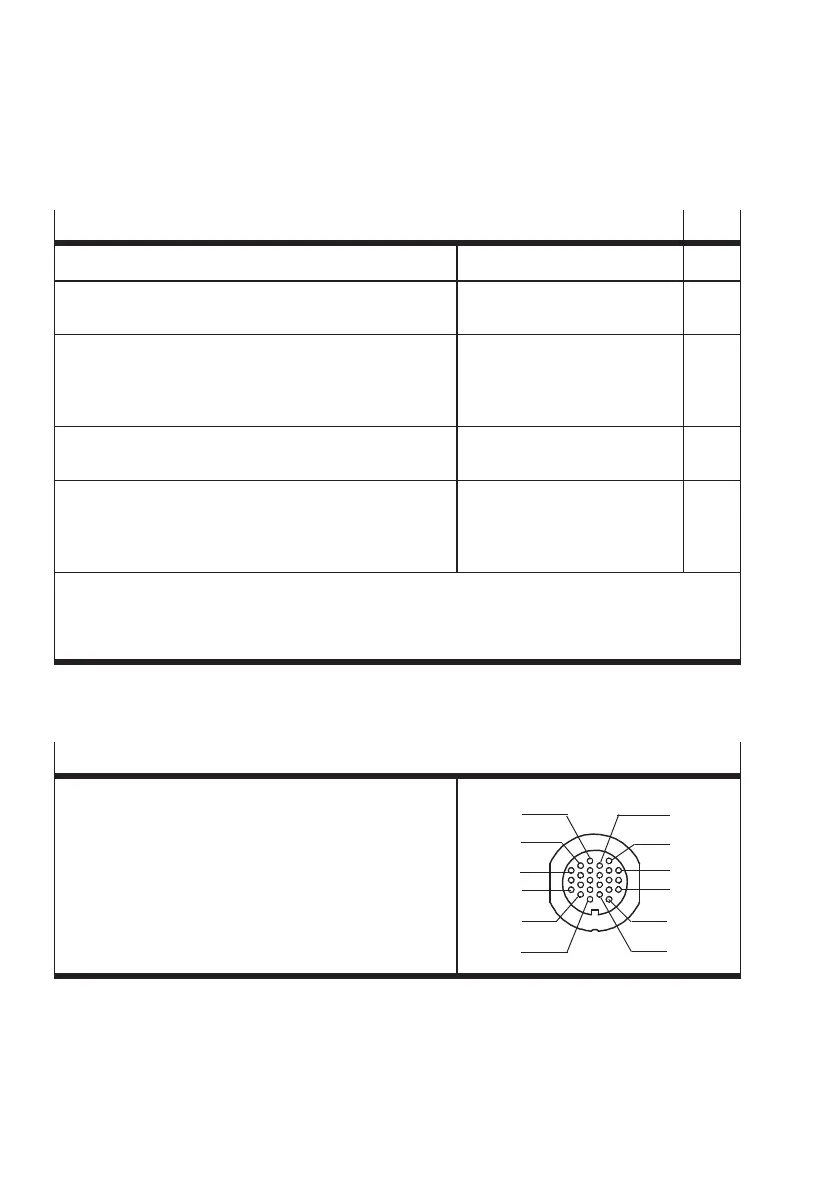

Electrical properties of the PLC interface

Inputs:

– Input current: . 30 mA

– Logical “1”: V

on

, 15 V

– Logical “0”: V

on

. 5V

Outputs:

– Max. current loading per channel:

700 mA

– Max. sum current of all outputs: 1 A

– PNP switching

1

3

7

4

8

12

13

16

21

17

22

24

Tab. 3/6: Electrical properties of the PL C interface

Loading...

Loading...